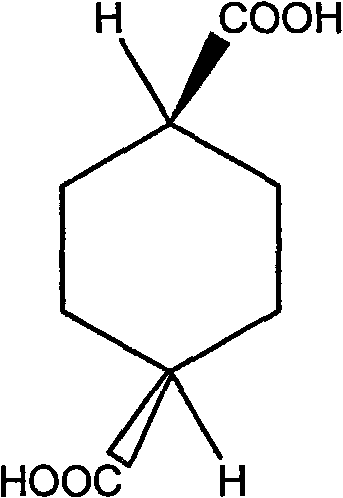

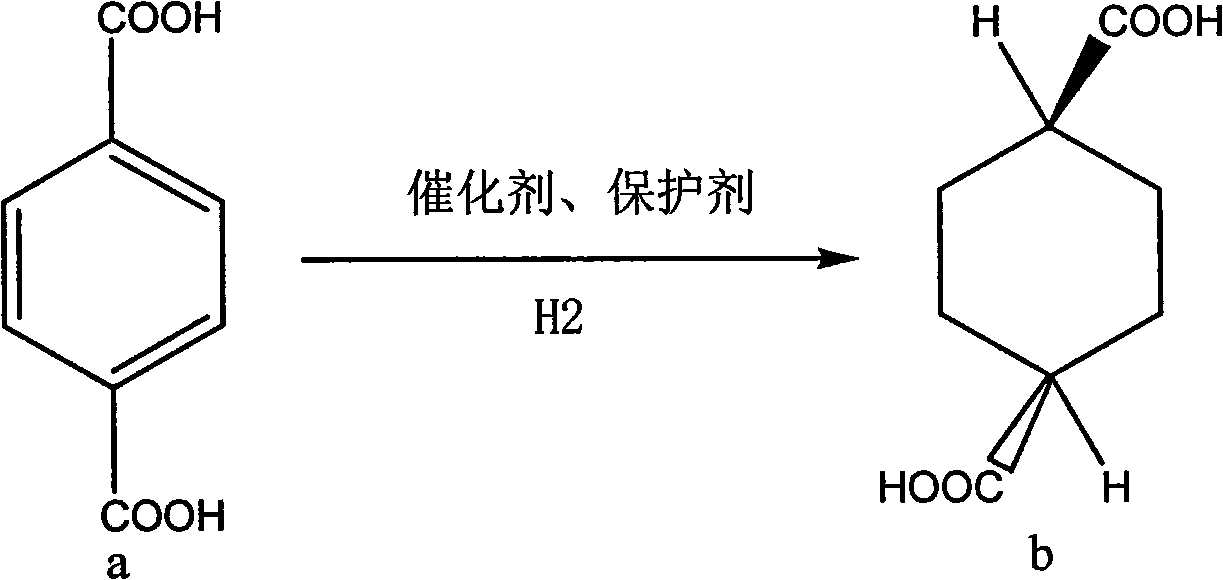

Synthesizing method for trans-1,4-cyclohexanedicarboxylic acid

A technology of cyclohexanedicarboxylic acid and a synthesis method, which is applied in the field of trans-1, can solve the problems of high content of cis-products and difficulties in pure trans-1,4-cyclohexanedicarboxylic acid, and achieve low cost and high raw material Easy to obtain and short synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 200g of terephthalic acid into the autoclave, add 15g of catalyst palladium carbon and 30g of protective agent ammonium hydroxide, then add 600g of water, first pass through nitrogen for three times, then pass through hydrogen for three times, and then pass through hydrogen to increase the pressure Stir to 4Mpa and keep it stable, stir and raise the temperature to 100°C, the reaction will accelerate hydrogen absorption, maintain the reaction temperature at 100-120°C, and continue to add hydrogen for 3 hours. After the reaction, the catalyst was filtered while it was hot, the filter cake was used mechanically, and the filtrate was cooled and then filtered to obtain a filter cake with a wet weight of 227 g, dried 191 g, a yield of 95.5%, and a content of trans-1,4-cyclohexanedicarboxylic acid of 98.3%. Apply the filtrate. The catalyst can be applied 13-15 times, and the protective agent can be applied repeatedly.

Embodiment 2

[0025] The amount of the catalyst was changed to 11 g, and the remaining reaction conditions were the same as in Example 1. The final yield was 84.3%, and the content of trans-1,4-cyclohexanedicarboxylic acid was 98.1%.

Embodiment 3

[0027] The amount of the catalyst was changed to 13g, and the rest of the reaction conditions were the same as in Example 1. The final yield was 93.1%, and the content of trans-1,4-cyclohexanedicarboxylic acid was 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com