Multipolymer emulsion, preparation method thereof, and cement mortar prepared from multipolymer emulsion

A technology of polymer emulsion and polymer, which is applied in the field of preparation of multi-component polymer emulsion, can solve the problems such as poor waterproof performance of mortar, and achieve the effect of improving compactness and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

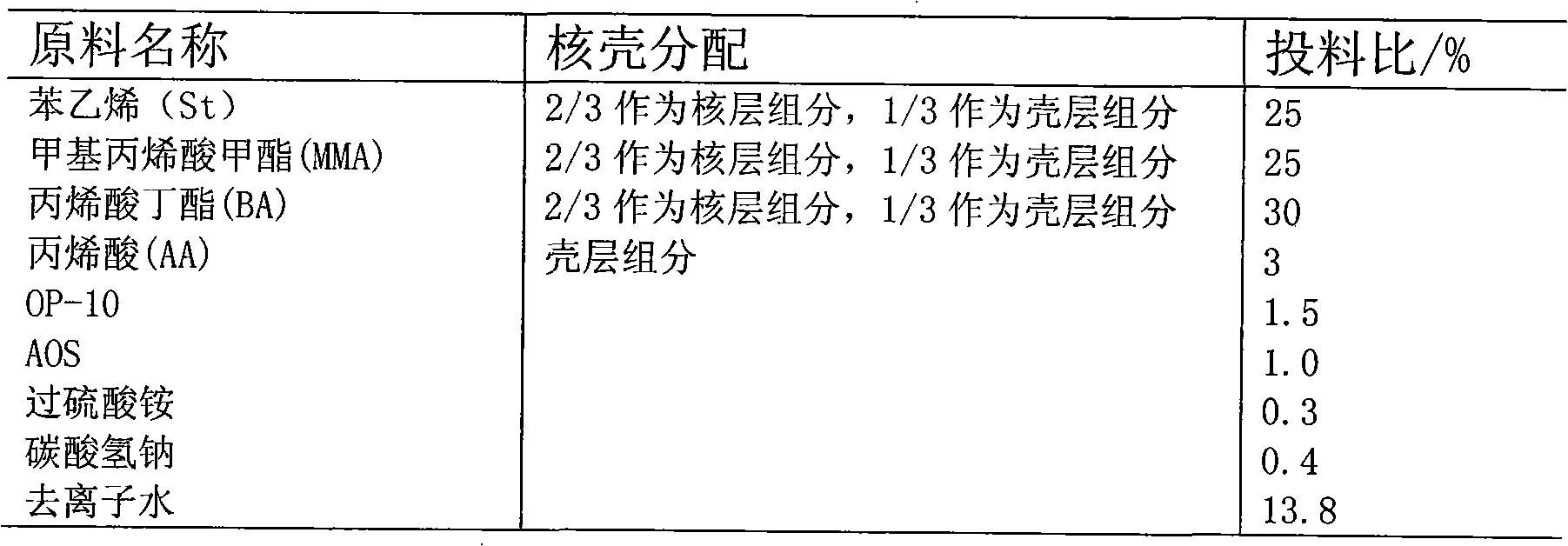

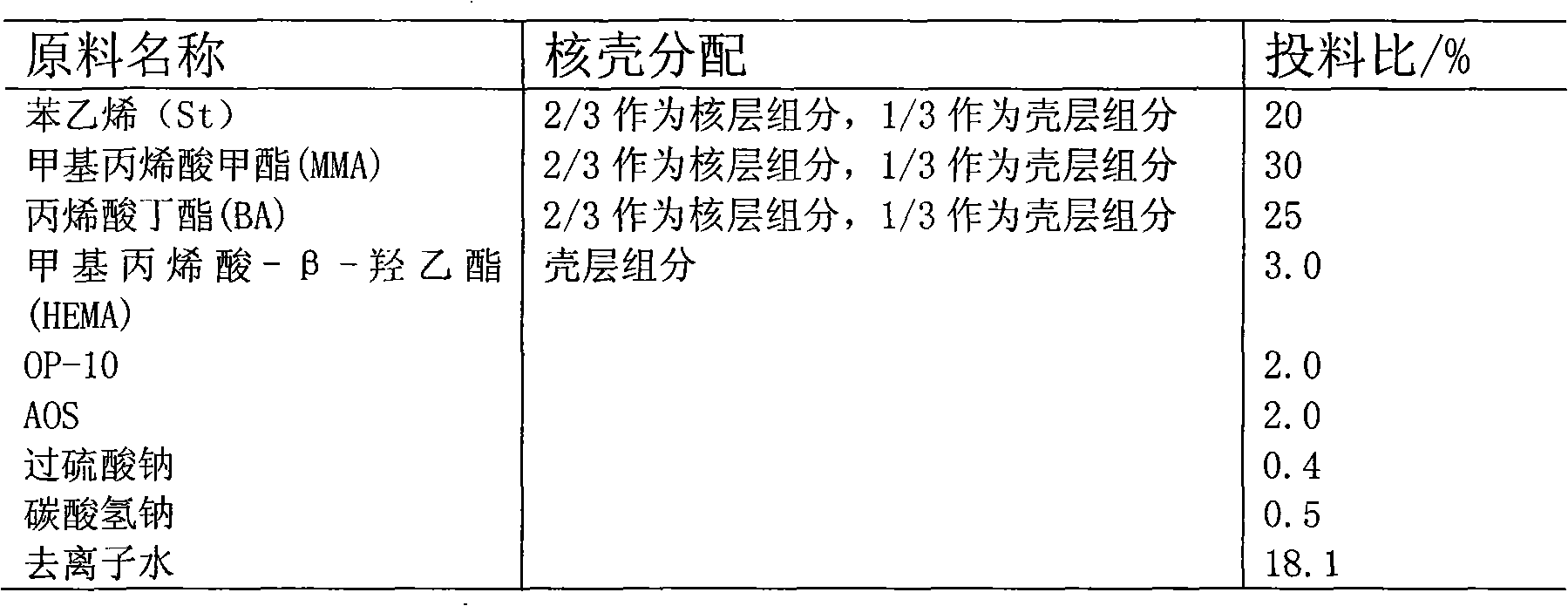

[0020] 1. The raw material formula of multi-component polymer emulsion is as follows:

[0021]

[0022] Two. the preparation method of multiple polymer emulsion is as follows:

[0023] Dissolve 2 / 3 each of emulsifier OP-10 and AOS in water, mix with 2 / 3 each of St, MMA, and BA, and stir rapidly for 40 minutes to obtain pre-emulsion A. Then the remaining amount of emulsifier was mixed with the remaining St, MMA, BA and AA, and stirred rapidly for 40 minutes to obtain pre-emulsion B. Add 2 / 3 amount of sodium bicarbonate solution to the pre-emulsion A, heat and stir and add 2 / 3 amount of ammonium persulfate solution dropwise, control the addition within 1 hour, after the dropwise addition is completed, the temperature is 70 ° C ~ 80 ° C Next, insulate and react for 1.5 hours to obtain a seed emulsion. In the seed emulsion, evenly add the pre-emulsion B dropwise, and add it within 1.5 hours. Insulate and react at 70°C to 80°C for 2 hours, raise the temperature to 90°C and co...

Embodiment 2

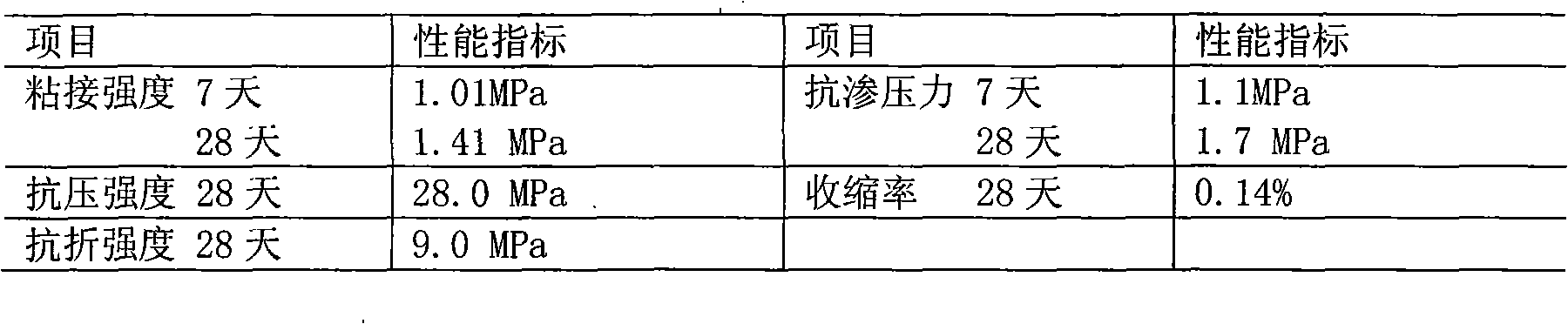

[0028] 1. The raw material formula of multi-component polymer emulsion is as follows:

[0029]

[0030] Two. the preparation method of multiple polymer emulsion is as follows:

[0031] Dissolve 2 / 3 each of emulsifier OP-10 and AOS in water, mix with 2 / 3 each of St, MMA, and BA, and stir rapidly for 30 minutes to obtain pre-emulsion A. Then the remaining amount of emulsifier was mixed with the remaining St, MMA, BA and HEMA, and stirred rapidly for 40 minutes to obtain pre-emulsion B. Add 2 / 3 amount of sodium bicarbonate solution to the pre-emulsion A, heat and stir and dropwise add 2 / 3 amount of sodium persulfate solution, control the addition within 1 hour, after the dropwise addition is completed, the temperature is 70 ° C ~ 80 ° C Next, heat preservation reaction for 1.0 hour to obtain seed emulsion. In the seed emulsion, evenly add the pre-emulsion B dropwise, and add it within 1.5 hours. Insulate and react at 70°C to 80°C for 2.5 hours, raise the temperature to 90°C...

Embodiment 3

[0036] 1. The raw material formula of multi-component polymer emulsion is as follows:

[0037]

[0038] Two. the preparation method of multiple polymer emulsion is as follows:

[0039] Dissolve 2 / 3 each of emulsifier OP-10 and AOS in water, mix with 2 / 3 each of St, MMA, and BA, and stir rapidly for 40 minutes to obtain pre-emulsion A. Then the remaining amount of emulsifier was mixed with the remaining St, MMA, BA, AA, and HEMA, and stirred rapidly for 40 minutes to obtain pre-emulsion B. Add 2 / 3 amount of sodium bicarbonate solution to the pre-emulsion A, heat and stir and dropwise add 2 / 3 amount of ammonium persulfate solution, control the addition within 1.5 hours, after the dropwise addition is completed, the temperature is 70 ° C ~ 80 ° C Next, heat preservation reaction for 2.0 hours to obtain seed emulsion. In the seed emulsion, evenly add the pre-emulsion B dropwise, and add it within 1.5 hours. Insulate and react at 70°C to 80°C for 2.5 hours, raise the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com