Motor rotor positioning system for hybrid vehicle and positioning method thereof

A technology for hybrid electric vehicles and motor rotors, which is applied in the field of automobile manufacturing to achieve improved performance, simple positioning methods, and the elimination of measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

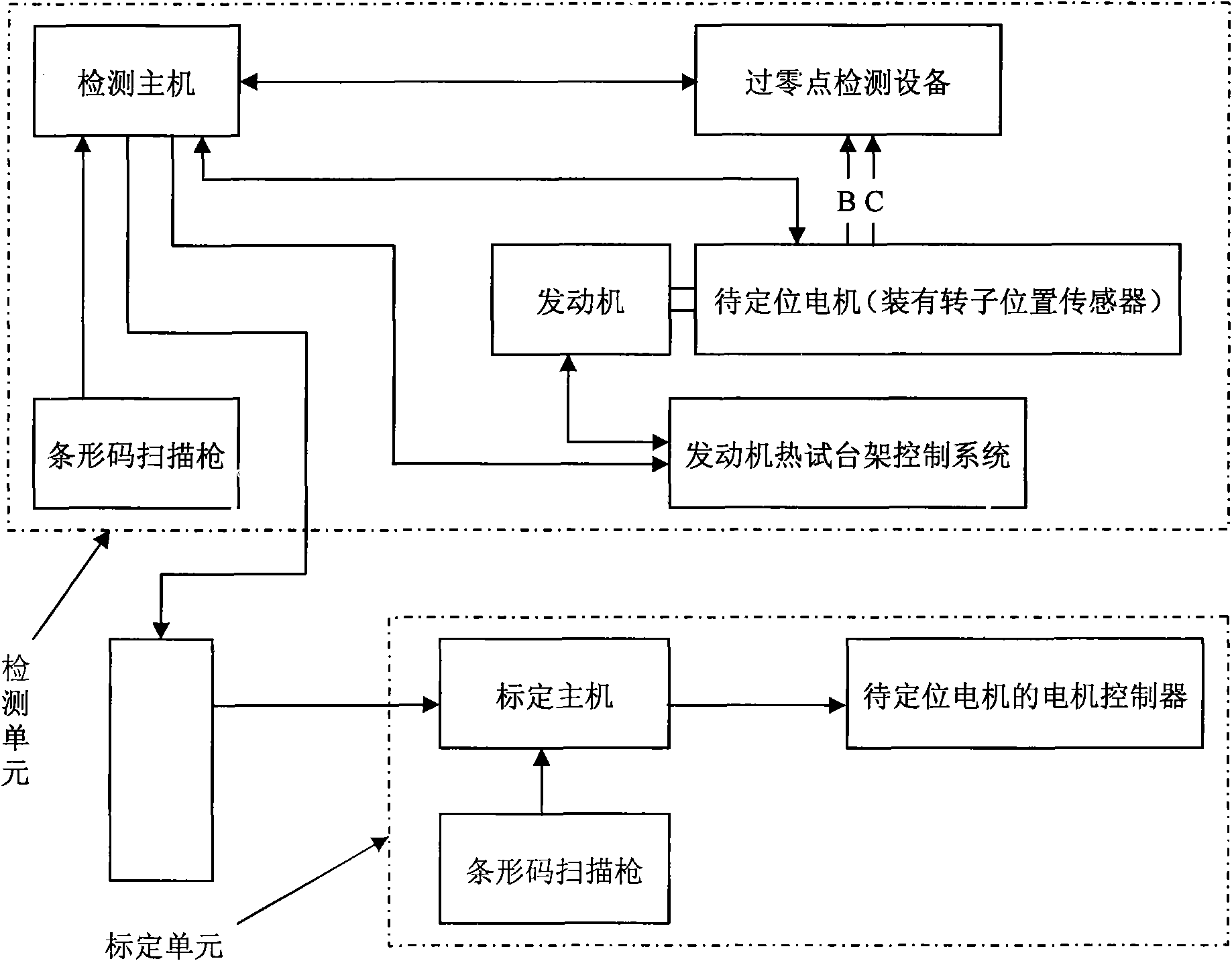

[0028] like figure 1 As shown, the hybrid vehicle motor rotor positioning system of this embodiment is composed of a detection unit and a calibration unit. , a barcode scanning gun for scanning motor barcodes, zero-crossing detection equipment and a motor rotor position sensor installed on the motor to be positioned, the detection host and engine hot test bench control system, barcode scanning gun, zero-crossing detection equipment and motor rotor The position sensor is connected; the calibration unit includes a barcode scanning gun and a calibration host, and the calibration host is connected to the motor controller of the motor to be positioned; the detection host and the calibration host are respectively connected to the storeable motor barcode number and rotor position angle through the network The database server connection for the value.

[0029] The detection host is a single-chip microcomputer with a network interface and its peripheral circuits.

[0030] The zero-cr...

Embodiment 2

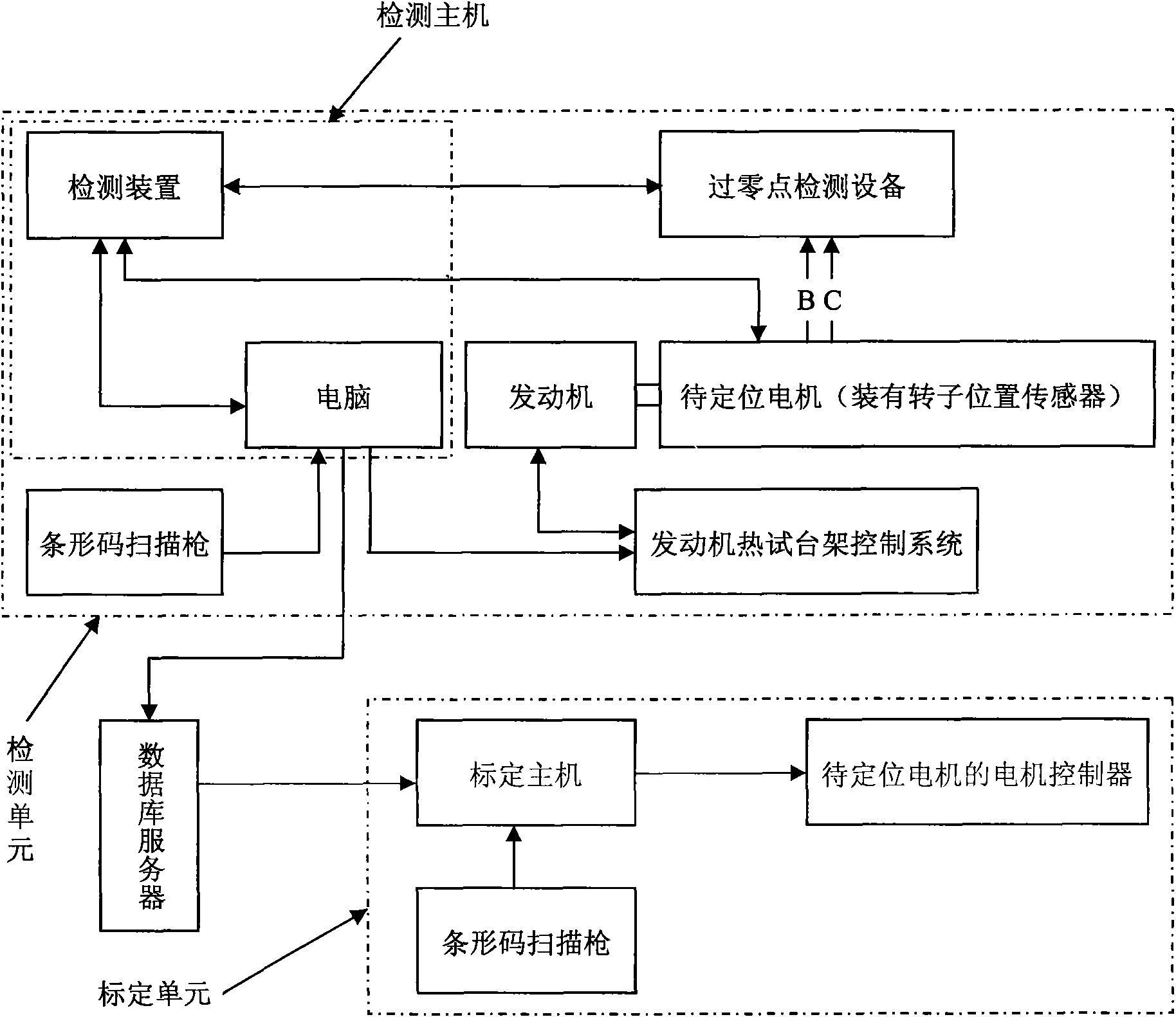

[0041] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that the detection host of this embodiment is a combination of a detection device and a computer. The detection device is composed of a single-chip microcomputer and its peripheral circuits. , so that the existing resources can be fully utilized, the single-chip circuit and development difficulty can be simplified, and the anti-interference performance of the CAN network is strong, which is suitable for the complex electromagnetic environment of the production line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com