Silicone resin, silicone composition, coated substrate, and reinforced silicone resin film

A silicone and resin film technology, applied in coating, fabric, transportation and packaging, etc., can solve the problems of low tear strength, low glass transition temperature, high brittleness, etc., achieve low thermal expansion coefficient, high thermal stability, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0098] The preparation method of reinforced silicone resin film according to the present invention comprises the following steps:

The fiber reinforcement is impregnated in a silicone composition comprising (A) a silicone resin and (B) an organic solvent, the silicone resin comprising (3-a) / 2 R 1 a Si-SiR 1 b o (3-b) / 2 (I) bis(methylsiloxane) unit and siloxane unit having particle form, wherein each R 1 is independently -H, hydrocarbyl or substituted hydrocarbyl, a is 0, 1 or 2, and b is 0, 1, 2 or 3; and

Cures the silicone resin impregnated with the fiber reinforcement.

[0099] In the first step of the method for preparing a reinforced silicone resin film, the fiber reinforcement is impregnated in a silicone composition comprising (A) a silicone resin and (B) an organic solvent, the silicone resin contains formula O (3-a) / 2 R 1 a Si-SiR 1 b o (3-b) / 2 (I) bis(methylsiloxane) unit and siloxane unit having particle form, wherein each R 1 is independently -H, hydr...

Embodiment 1

[0130] Disilane composition A (30 g) was mixed with 120 g of methyl isobutyl ketone (MIBK) and 38.4 g of anhydrous methanol. HCl produced by the reaction was vented from the opening of the flask. The liquid mixture was placed in a sealed bottle, cooled in an ice-water bath, and then transferred to a top-mounted addition funnel of a three-neck round bottom flask equipped with a stirrer and thermometer. Will contain 120g of deionized water and 51.8g of ORGANOSILICASOL TM The mixture of IPA-ST was placed in a flask and cooled to 2-4°C with an external ice water bath. The mixture in the addition funnel was added continuously to the cooled deionized water / colloidal silica mixture over a period of 10 minutes, during which time the temperature of the mixture increased by 3-5°C. After the addition was complete, the mixture was stirred for 1 hour in an ice bath. The flask was then heated to 50-75°C with a water bath and maintained at this temperature for 1 hour. The mixture was co...

Embodiment 2

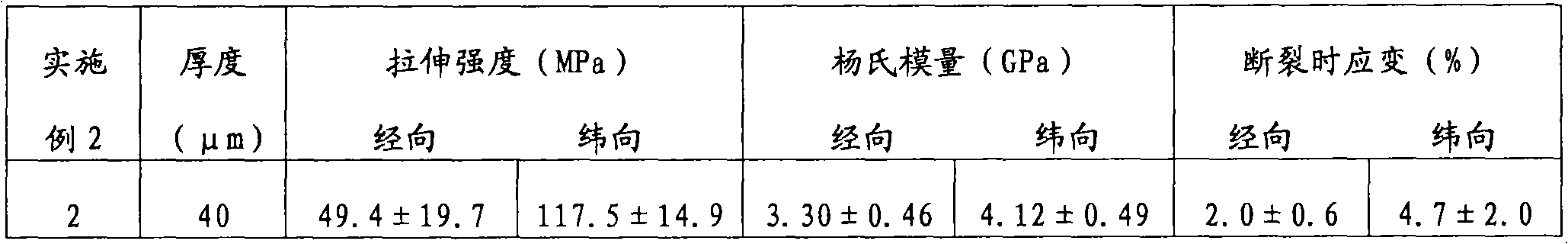

[0131] A glass fabric (38.1 cm x 8.9 cm) was impregnated with the silicone composition of Example 1 by passing the fabric through the composition at a rate of about 5 cm / s. The impregnated fabric was then hung vertically in an air circulating oven and the silicone resin was cured by heating the impregnated fabric from room temperature to 150°C at 5°C / min. and then maintaining the temperature at 150°C for 10 minutes. Turn off the oven and allow the reinforced silicone resin film to cool to room temperature. The steps of impregnating, curing and cooling were repeated two more times except that the silicone resin was heated by heating the impregnated fabric from room temperature to 200°C at 5°C / min. and maintaining the temperature at 200°C for 1 hour. solidified. Table 1 shows the mechanical properties of the reinforced silicone resin film.

Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com