Coloring matter-sensitized photoelectric conversion element, process for producing the coloring matter-sensitized photoelectric conversion element, electronic equipment, semiconductor electrode, and p

A photoelectric conversion and semiconductor technology, applied in semiconductor devices, capacitors, photovoltaic power generation, etc., can solve problems such as insufficient light absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

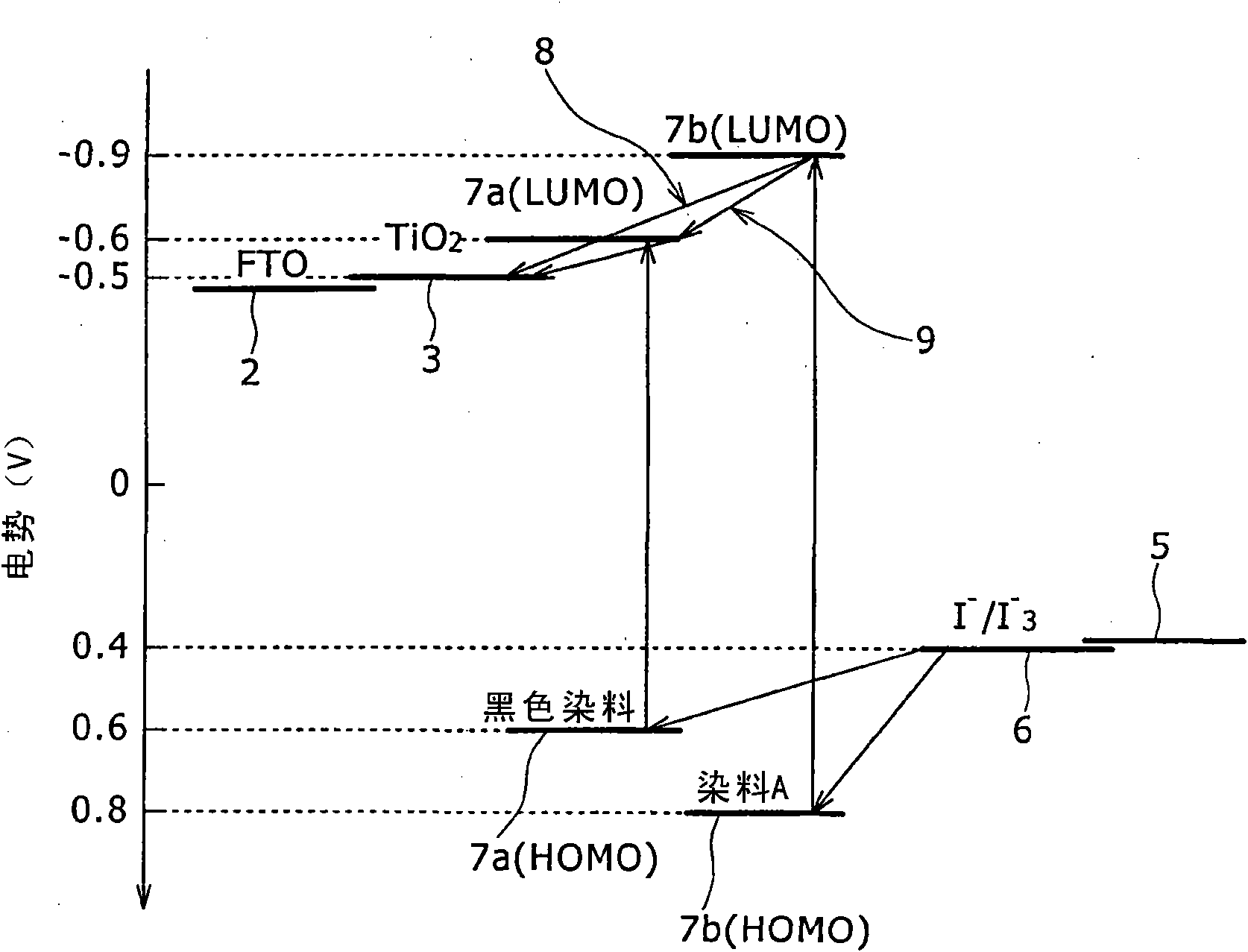

[0093] TiO 2 Fine particles are used as semiconductor fine particles. See Hironori Arakawa, "Recent Advances in Research and Development for Dye-Sensitized Solar Cells" (CMC) pp. 45-47 (2001) for the method of producing TiO as follows 2 A pasty dispersion in which the particles are dispersed. At room temperature, 125 mL of titanium isopropoxide was slowly added dropwise to 750 mL of 0.1 M nitric acid aqueous solution while stirring. After the dropwise addition was completed, the solution was transferred to a thermally stable solution tank at 80° C., and stirred for 8 hours to obtain a cloudy translucent sol solution. Then, the sol solution was cooled to room temperature, filtered through a glass filter, and its volume was measured to be 700 mL. The obtained sol solution was transferred to an autoclave, hydrothermally treated at 220° C. for 12 hours, and then dispersed by ultrasonic treatment for 1 hour. Then, the solution was concentrated using an evaporator at 40°C so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com