Low temperature preparation method of yttrium aluminum garnet rare earth phosphor powder

The technology of rare earth phosphor and yttrium aluminum garnet is applied in the field of materials to achieve the effects of low sintering temperature, good luminescence performance and easy mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] To prepare with general formula Y 2.96 Ce 0.04 Al 5 o 12 (M in the general formula is Ce 3+ , x is 0.04, and y is 0) the rare earth phosphor 10g that represents is example, used raw material and preparation method thereof are as follows:

[0030] 1. Pretreatment of raw materials

[0031] Pre-fire the yttrium oxide in a high-temperature furnace at 850°C for 2 hours to remove the moisture in it.

[0032] 2. Ingredients

[0033] According to formula Y 2.96 Ce 0.04 Al 5 o 12 Carry out batching, in the formula M is Ce 3+ , x is Ce 3+ The number of moles, x is 0.04, weigh 5.610g Y 2 o 3 Dissolve with nitric acid in a beaker and mix with 34.490g Al(NO 3 ) 3 9H 2 O, 0.220gCe(NO 3 ) 3 Mix to prepare a mixed solution. Adjust the pH of the mixed solution to 4-6 with a solution with a volume ratio of ammonia water and absolute ethanol of 1:5, add citric acid whose mass is 8 times the total amount of raw materials, and stir at 60-100°C for 1-2 hours to form a light ...

Embodiment 2

[0037] To prepare with general formula Y 2.94 Tb 0.06 Al 5 o 12 (M in the general formula is Tb 3+ , x is 0.06, and y is 0) the rare earth phosphor 10g that represents is example, used raw material and preparation method thereof are as follows:

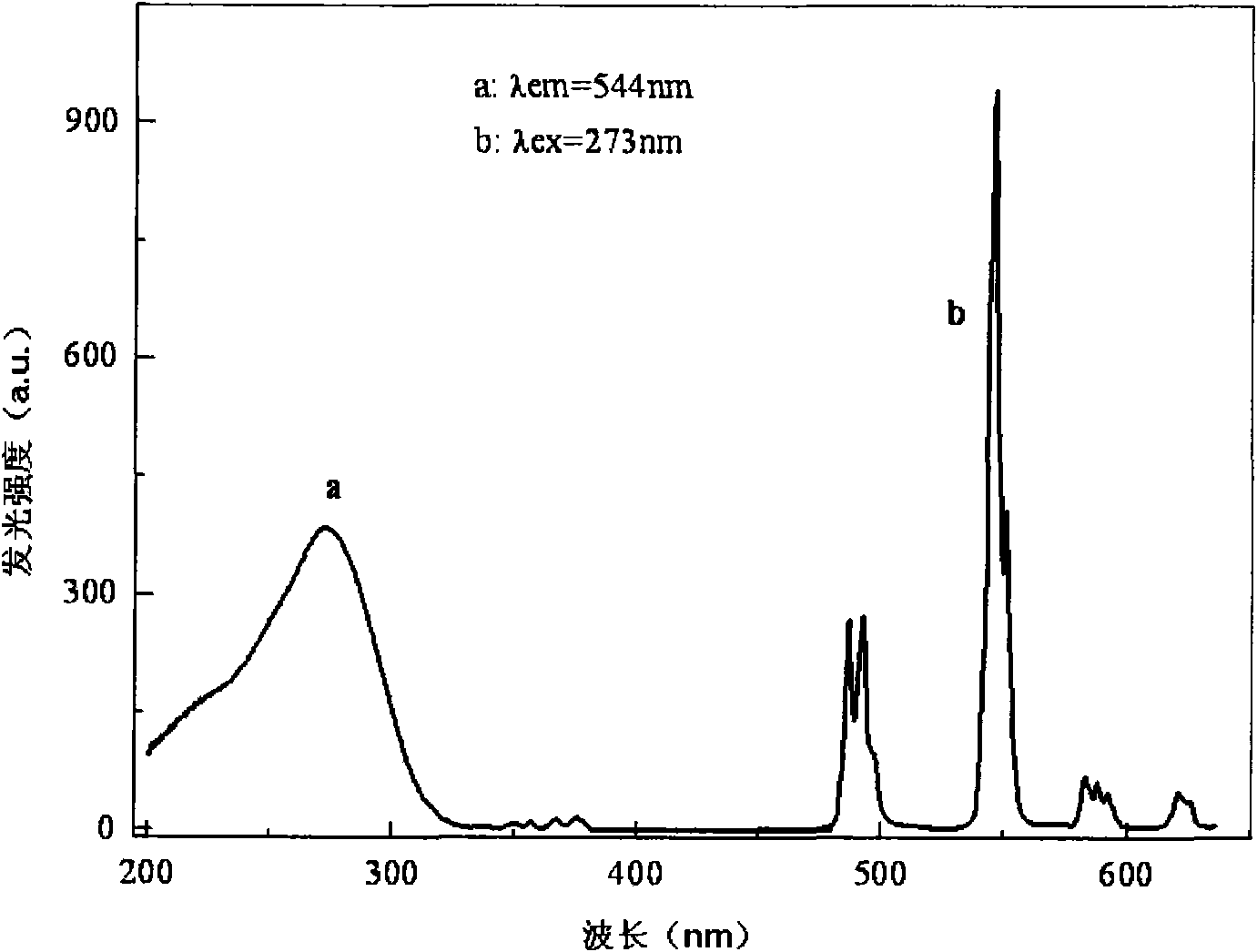

[0038] In batching step 2, according to the general formula Y 2.94 Tb 0.06 Al 5 o 12 For batching, M is Tb in the formula 3+ , x is Tb 3+ The number of moles, x is 0.06, weigh 5.560g Y 2 o 3 Dissolve with nitric acid in a beaker and mix with 31.480gAl(NO 3 ) 3 9H 2 O, 0.350g Tb(NO 3 ) 3 Mix to prepare a mixed solution. Other steps in this step are the same as in Example 1, and a fluffy slightly yellowish precursor is obtained. Other steps are identical with embodiment 1, prepare Y 2.94 Tb 0.06 Al 5 o 12 Green phosphor, the prepared Y 2.94 Tb 0.06 Al 5 o 12 The green fluorescent powder is tested with a fluorescence spectrometer, and the excitation and emission spectrograms are shown in figure 1 , the surface m...

Embodiment 3

[0040] To prepare with general formula Y 2.94 Tb 0.06 Al 4.7 Ga 0.3 o 12 (M in the general formula is Tb 3+ , x is 0.06, and y is 0.3) the rare earth phosphor 10g that represents is example, used raw material and preparation method thereof are as follows:

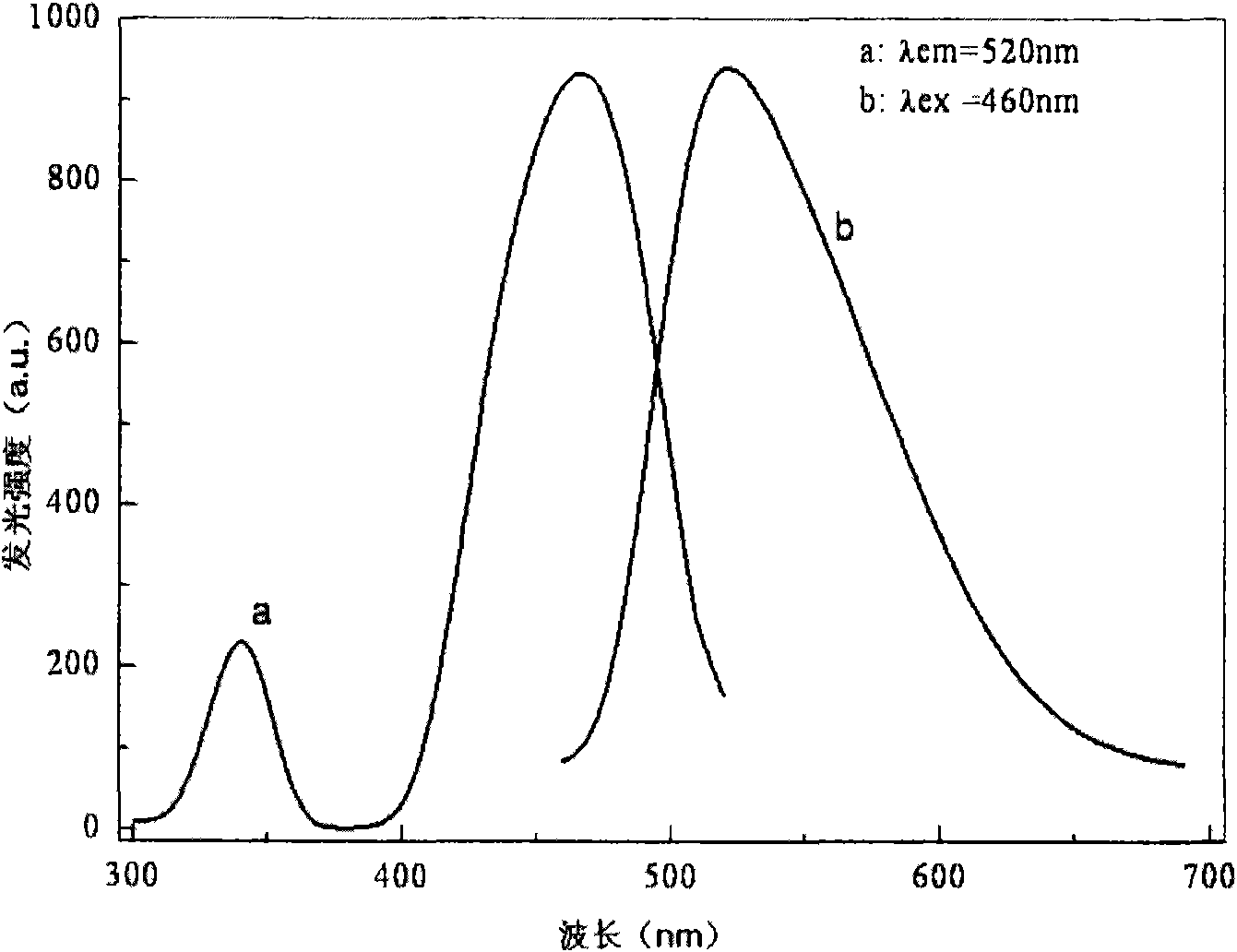

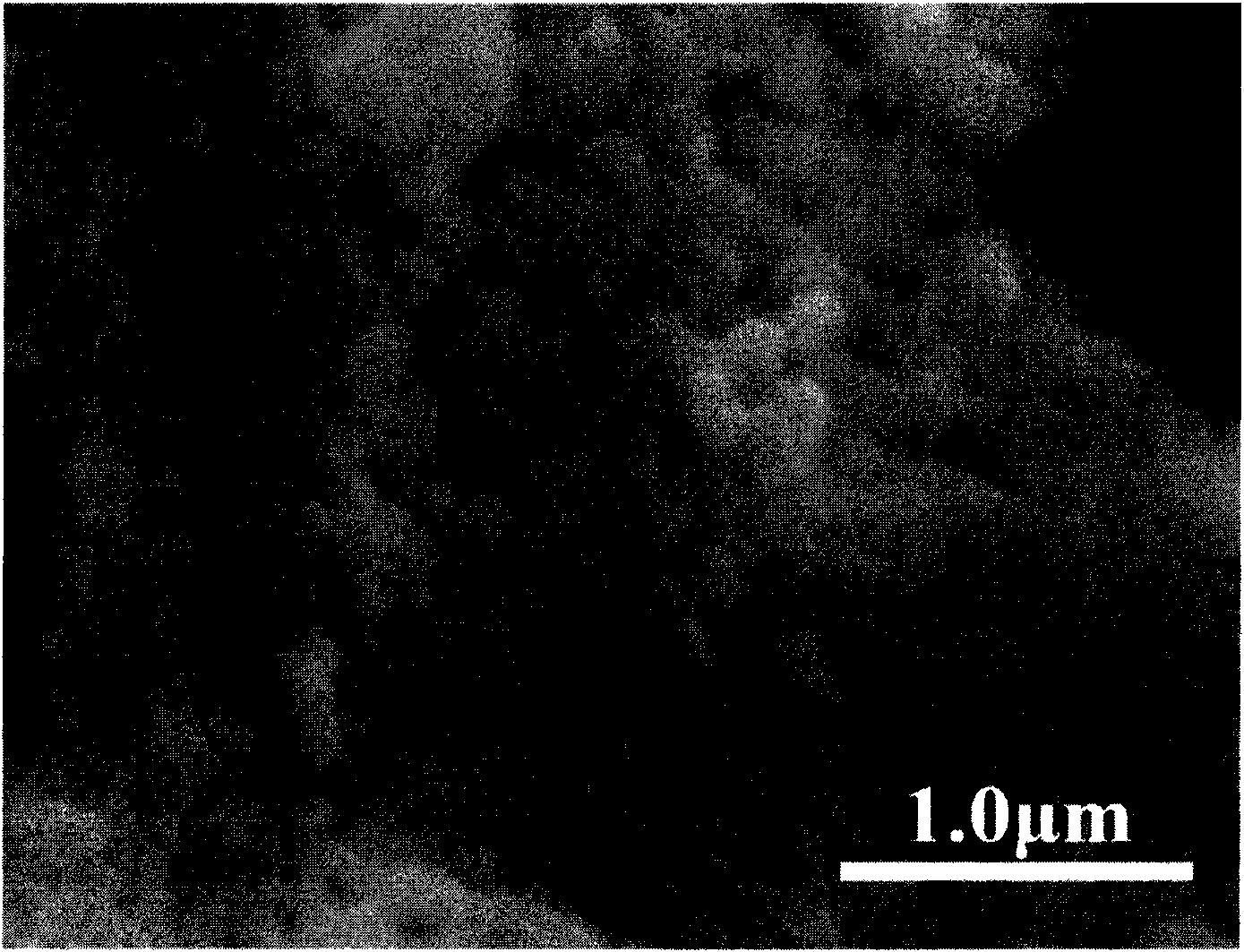

[0041] In batching step 2, according to the general formula Y 2.94 Tb 0.06 Al 4.7 Ga 0.3 o 12 For batching, where y is Ga 3+ The number of moles, y is 0.3, weigh 5.440gY 2 o 3 and 0.460gGa 2 o 3 Dissolve with nitric acid in a beaker and mix with 28.870gAl(NO 3 ) 3 9H 2 O, 0.340g Tb(NO 3 ) 3 Mix to prepare a mixed solution. Other steps in this step are the same as in Example 1. Other steps are identical with embodiment 1, prepare Y 2.94 Tb 0.06 Al 4.7 Ga 0.3 o 12 Green phosphor, the prepared Y 2.94 Tb 0.06 Al 4.7 Ga 0.3 o 12 The green fluorescent powder is tested with a fluorescence spectrometer and a cathode ray spectrometer, and the excitation and emission spectrograms are shown in Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com