Movable device for effectively collecting and processing algae pollutant

A technology of treatment device and post-treatment device, which is applied in the direction of flocculation/sedimentation water/sewage treatment, energy wastewater treatment, and cleaning of open water surface, etc. It can solve the problem of high production cost, difficult to popularize and apply, and dehydration of algae pulp with low concentration and other issues to achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

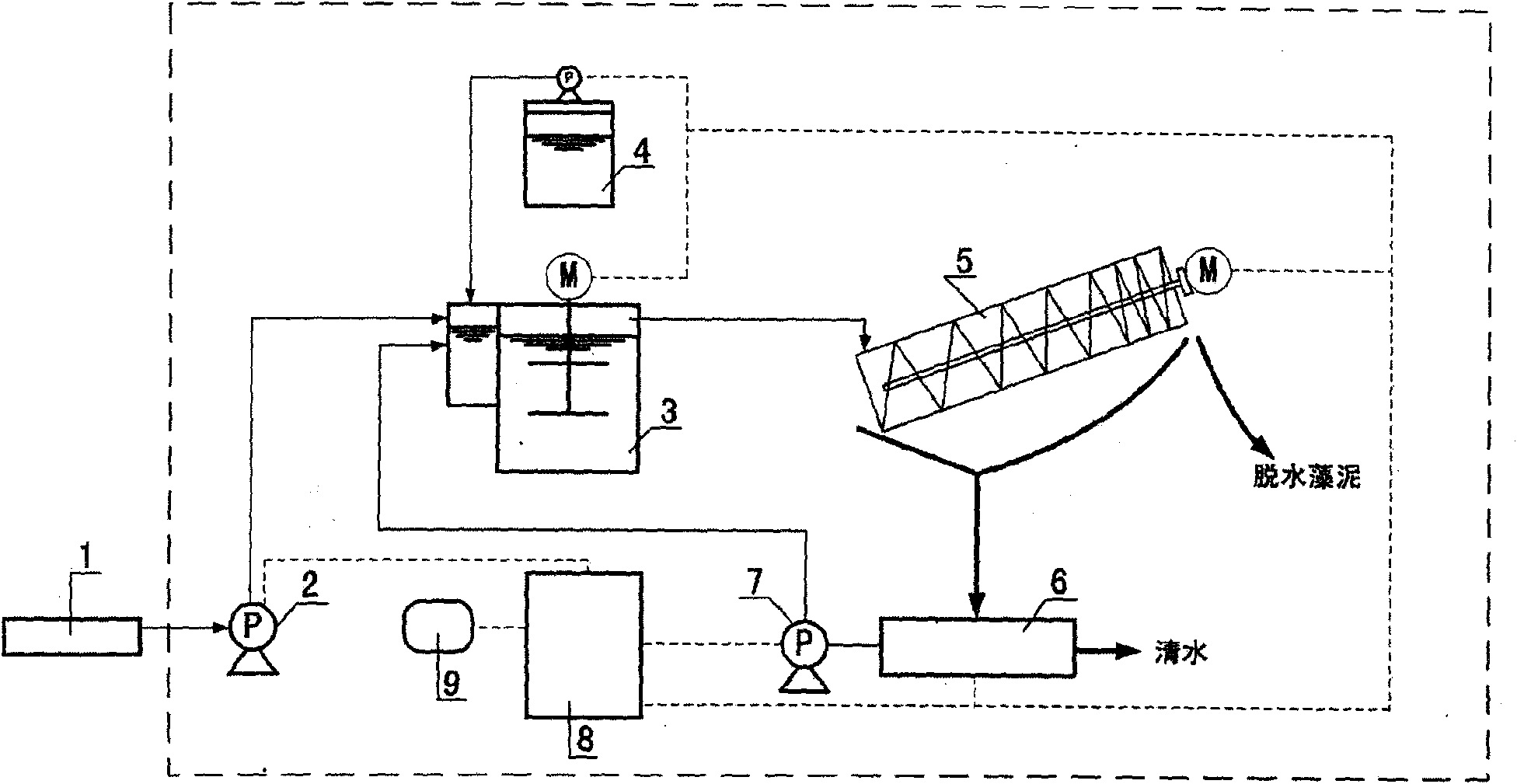

[0009] As shown in the figure, the present invention includes an algae slurry scraping device 1, an algae slurry delivery pump 2, a flocculation stirring tank 3, an algae slurry dehydrator 5, a post-processing device 6, and an algae slurry return pump 7. The algae slurry delivery Pump 2, flocculation mixing tank 3, algae pulp dehydrator 5, and algae pulp return pump 7 are sequentially closed-loop connected according to the process sequence and integrated with the power supply device 9 and control device 8 on the mobile equipment, that is, the algae pulp delivery pump 2 The output pipe is connected to the flocculation stirring tank 3, the flocculation stirring tank 3 is connected to the algal pulp dehydrator 5, the algal pulp dehydrator 5 is connected to the post-processing device 6, the post-processing device 6 is connected to the suction port of the algal pulp return pump 7, and the algal pulp return pump 7 is arranged The outlet communicates with the flocculation stirring tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com