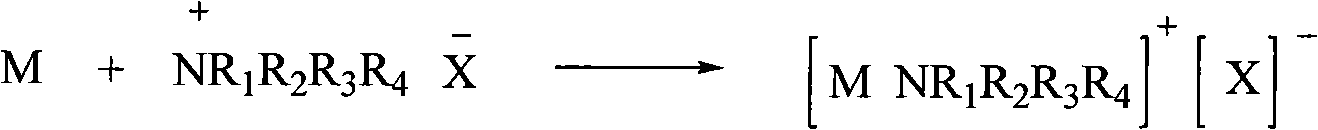

Method for absorbing SO2 gas by using halogenated alkyl quaternary ammonium salt ionic liquid

A quaternary ammonium salt ion and ionic liquid technology, applied in the field of organic wastewater treatment, can solve the problems of low SO2 solubility, long generation process, high viscosity, etc., and achieve the effects of good environmental and social benefits, high absorption efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1), the experimental device of synthesizing ionic liquid is reaction kettle, condensing device, stirring device and vacuum drying device. Put the accurately weighed caprolactam into the reaction kettle, turn on the stirrer to stir, and gradually add an appropriate amount of tetrabutylammonium chloride. And react at 80°C for 10h. Then the obtained liquid was dried in a vacuum drying oven at 50° C. for 1 h to finally obtain an ionic liquid of caprolactam-tetrabutylammonium chloride.

[0022] 2) Put the accurately weighed ionic liquid of caprolactam-tetrabutylammonium chloride into the absorber, and keep the temperature constant at 25°C. Feed SO into the absorber at a rate of 10mL / min 2 gas. The outlet of the absorption tail gas is passed into the sodium hydroxide solution to absorb SO 2 exhaust. Weigh the absorber at regular intervals until constant weight. Equilibrium SO 2 The mole fraction solubility in ionic liquid is 0.69.

Embodiment 2

[0024] 1), the experimental device of synthesizing ionic liquid is reaction kettle, condensing device, stirring device and vacuum drying device. Put the accurately weighed caprolactam into the reaction kettle, turn on the stirrer to stir, and gradually add an appropriate amount of ammonium thiocyanate. And react at 80°C for 10h. Then the obtained liquid was dried in a vacuum drying oven at 50° C. for 1 h, and finally the caprolactam-ammonium thiocyanate ionic liquid was obtained.

[0025] 2) Put the accurately weighed caprolactam-ammonium thiocyanate ionic liquid into the absorber, and keep the temperature constant at 50°C. Feed SO into the absorber at a rate of 10mL / min 2 gas. The outlet of the absorption tail gas is passed into the sodium hydroxide solution to absorb SO 2 exhaust. Weigh the absorber at regular intervals until constant weight. Equilibrium SO 2 The mole fraction solubility in ionic liquid is 0.75.

Embodiment 3

[0027] 1), the experimental device of synthesizing ionic liquid is reaction kettle, condensing device, stirring device and vacuum drying device. Put accurately weighed urea into the reaction kettle, turn on the stirrer to stir, and gradually add an appropriate amount of hydroxyethyltrimethylammonium chloride. And react at 120°C for 10h. Then the obtained liquid was dried in a vacuum drying oven at 50° C. for 1 h to finally obtain an ionic liquid of urea-hydroxyethyltrimethylammonium chloride.

[0028] 2) Put an accurately weighed ionic liquid of urea-hydroxyethyltrimethylammonium chloride into the absorber, and keep the temperature constant at 80°C. Feed SO into the absorber at a rate of 10mL / min 2gas. The outlet of the absorption tail gas is passed into the sodium hydroxide solution to absorb SO 2 exhaust. Weigh the absorber at regular intervals until constant weight. Equilibrium SO 2 The mole fraction solubility in ionic liquid is 0.64.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com