Bismuthate lead-free sealing glass material with low melting point and preparation method thereof

A glass material with low melting point technology, applied in the field of bismuth salt low melting point lead-free sealing glass material and its preparation, can solve the problems of high sealing temperature, achieve low sealing temperature, overcome easy crystallization, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

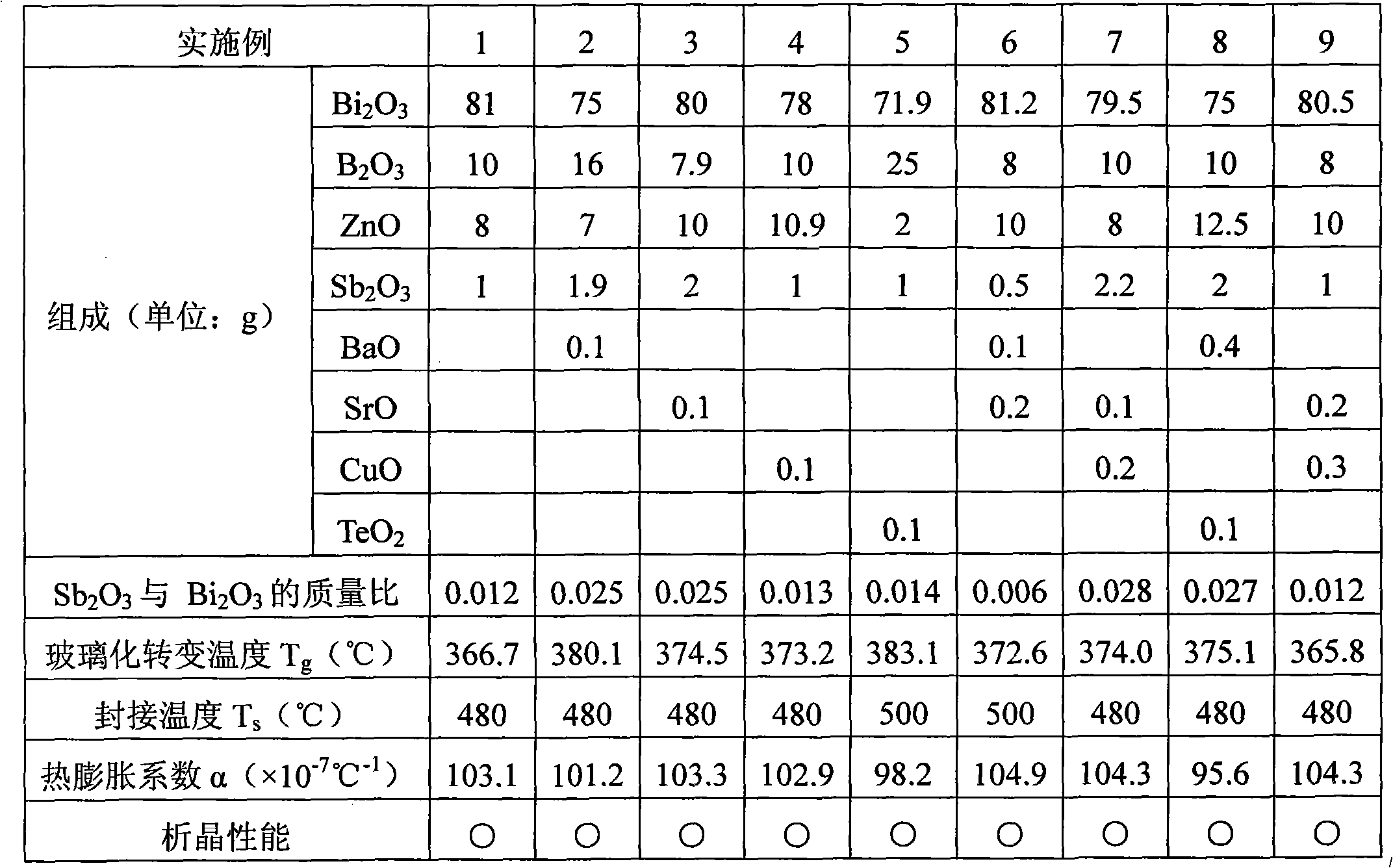

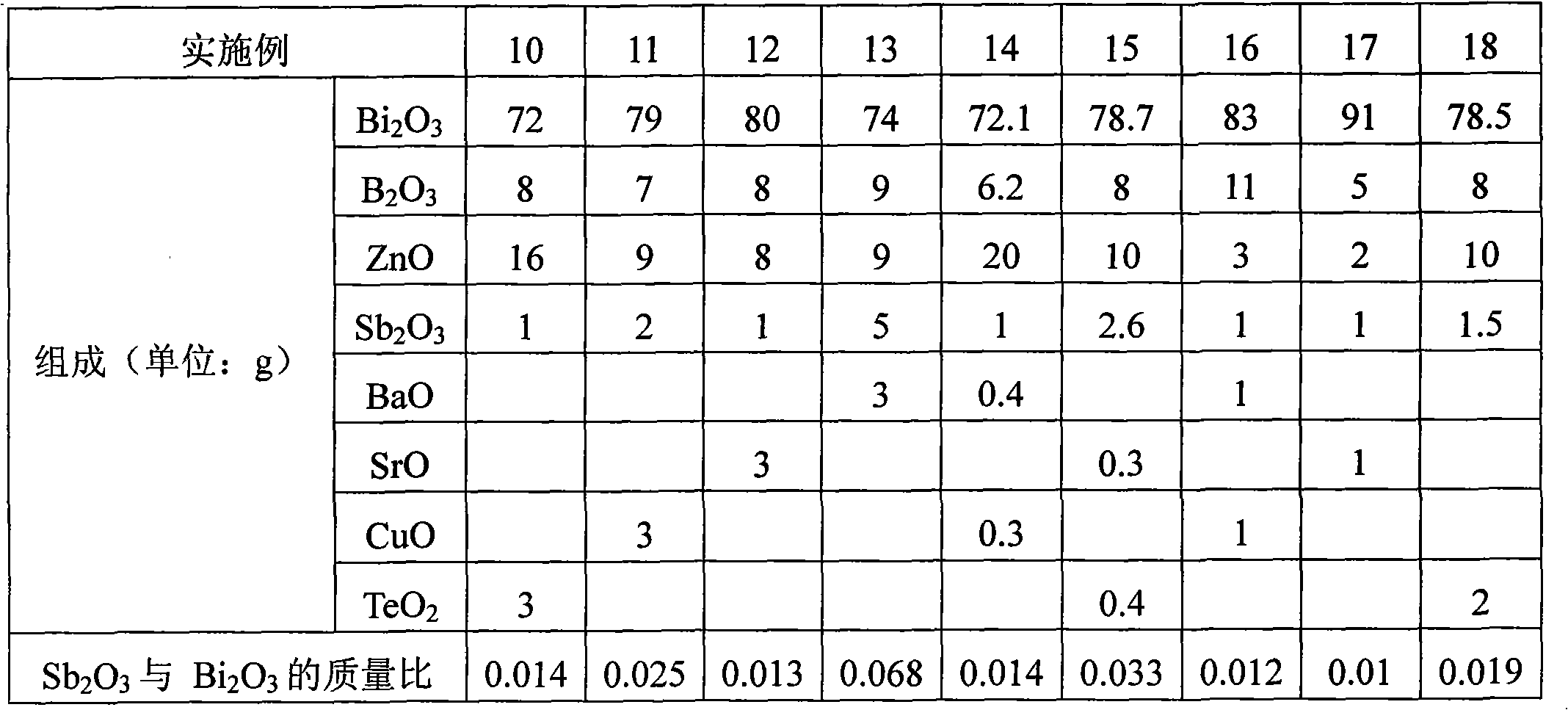

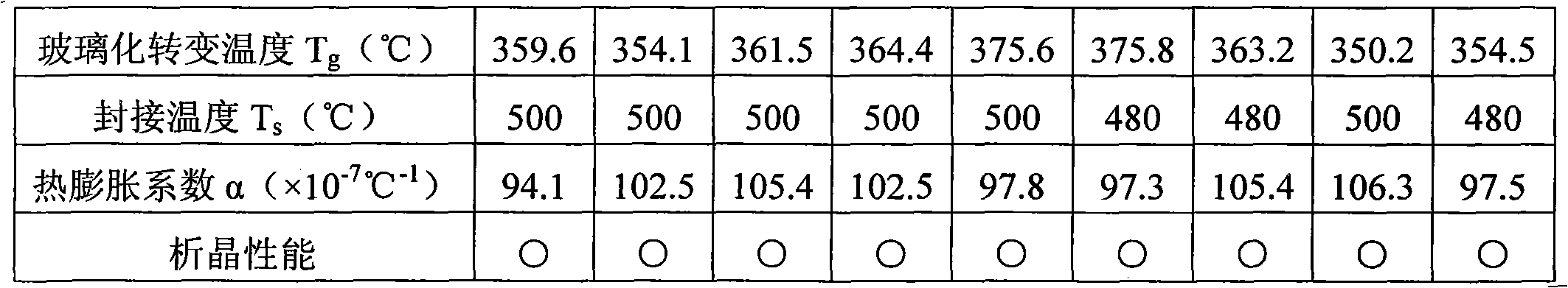

[0027] Bismuth salt low-melting-point lead-free sealing glass material and preparation method thereof of the present invention include essential oxide component Bi 2 o 3 , B 2 o 3 , ZnO, Sb 2 o 3 And adjust the oxide composition BaO, SrO, CuO and TeO 2 , and its mass percentages are: 71-91% Bi 2 o 3 , 5-25% B 2 o 3 , 2-20% ZnO, 0.5-5% Sb 2 o 3 , 0~3% BaO, 0~3% SrO, 0~3% CuO and 0~3% TeO 2 .

[0028] The present invention will be further described in detail below in conjunction with specific embodiments.

[0029] Examples 1-18 are specific examples of preparing the bismuthate low melting point lead-free sealing glass material of the present invention. Each embodiment weighs a total of 100 g of raw materials according to the mass percentage content of each component. The usage of each raw material is shown in Table 1 and Table 2. Examples 1-18 prepare the bismuth salt low melting point lead-free sealing glass material of the present invention. The raw materials use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Average coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com