Method for improving gluconobacter oxydans to produce 2-keto-L-gulonic acid

A technology of Gluconobacter oxydans and Gulonic acid, which is applied in the field of microbial fermentation, can solve the problems of increased cost, slow growth, and increased cost, and achieve the effects of reducing dosage, increasing growth speed, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

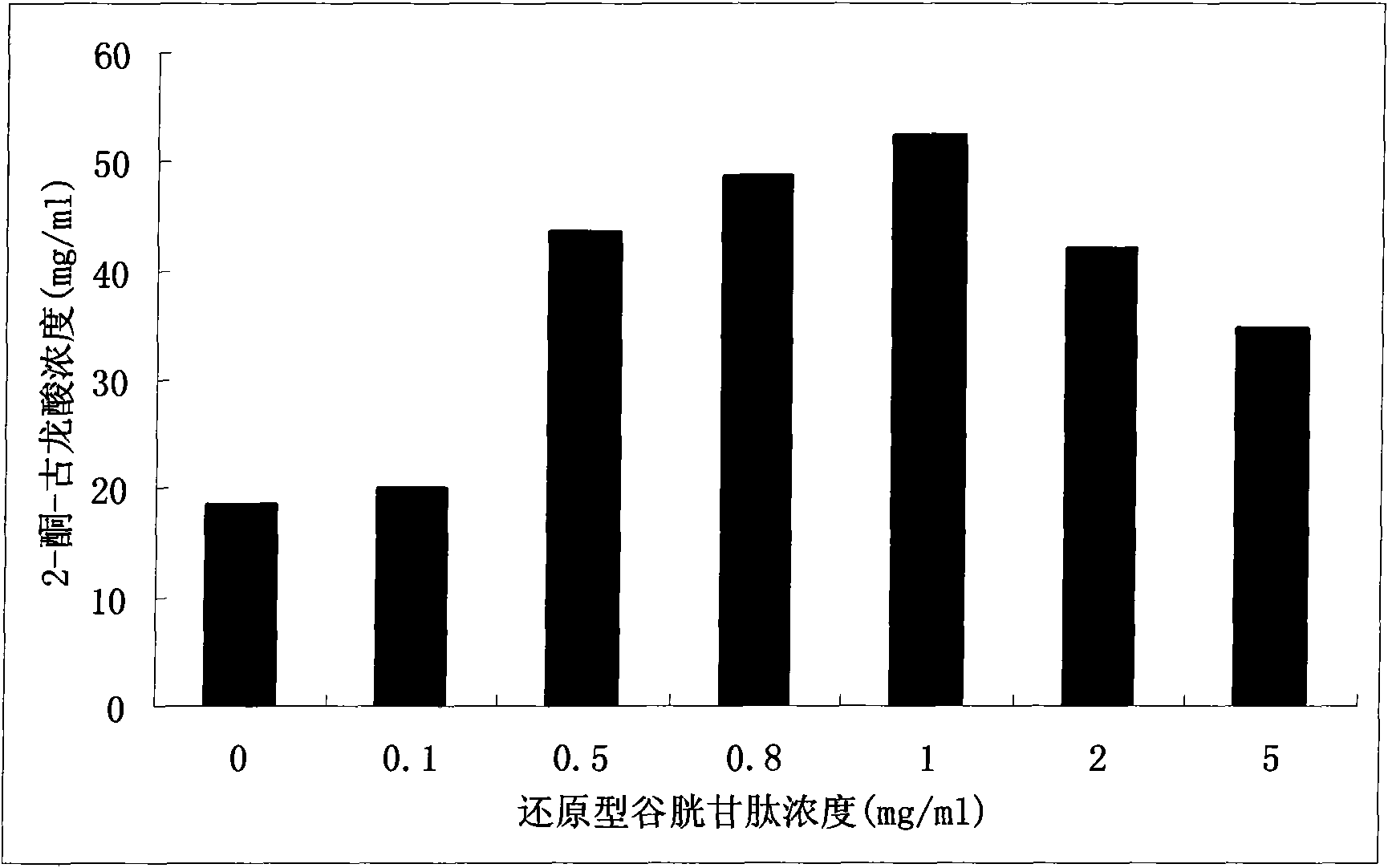

[0031] The method for improving the production of 2-keto-L-gulonic acid by Gluconobacter oxydans comprises the following steps:

[0032] (1) Seed cultivation:

[0033] Weigh: L-sorbose 20g, corn steep liquor 3g, beef extract 3g, yeast extract powder 3g, urea 1g, peptone 10g, KH 2 PO 4 1g, MgSO 4 0.2g, CaCO 3 Add 1 g of water to 1 L, adjust the pH to 6.8, and sterilize at 121°C for 20 minutes to make a seed medium;

[0034] Inoculate Gluconobacter oxydans (Gluconobacter oxydans) CGMCC NO.1.110 on the slant into the seed medium, shake at 30°C and 220r / min on a shaker, and cultivate for 36 hours to prepare a seed culture solution;

[0035] (2) Fermentation:

[0036] Weighing: L-sorbose 80g, corn steep liquor 20g, urea 12g, KH 2 PO 4 1g, MgSO 4 0.5g, CaCO 3 Add 5 g of water to 1 L, adjust the pH to 7.0, and sterilize at 121°C for 20 minutes to make a fermentation medium;

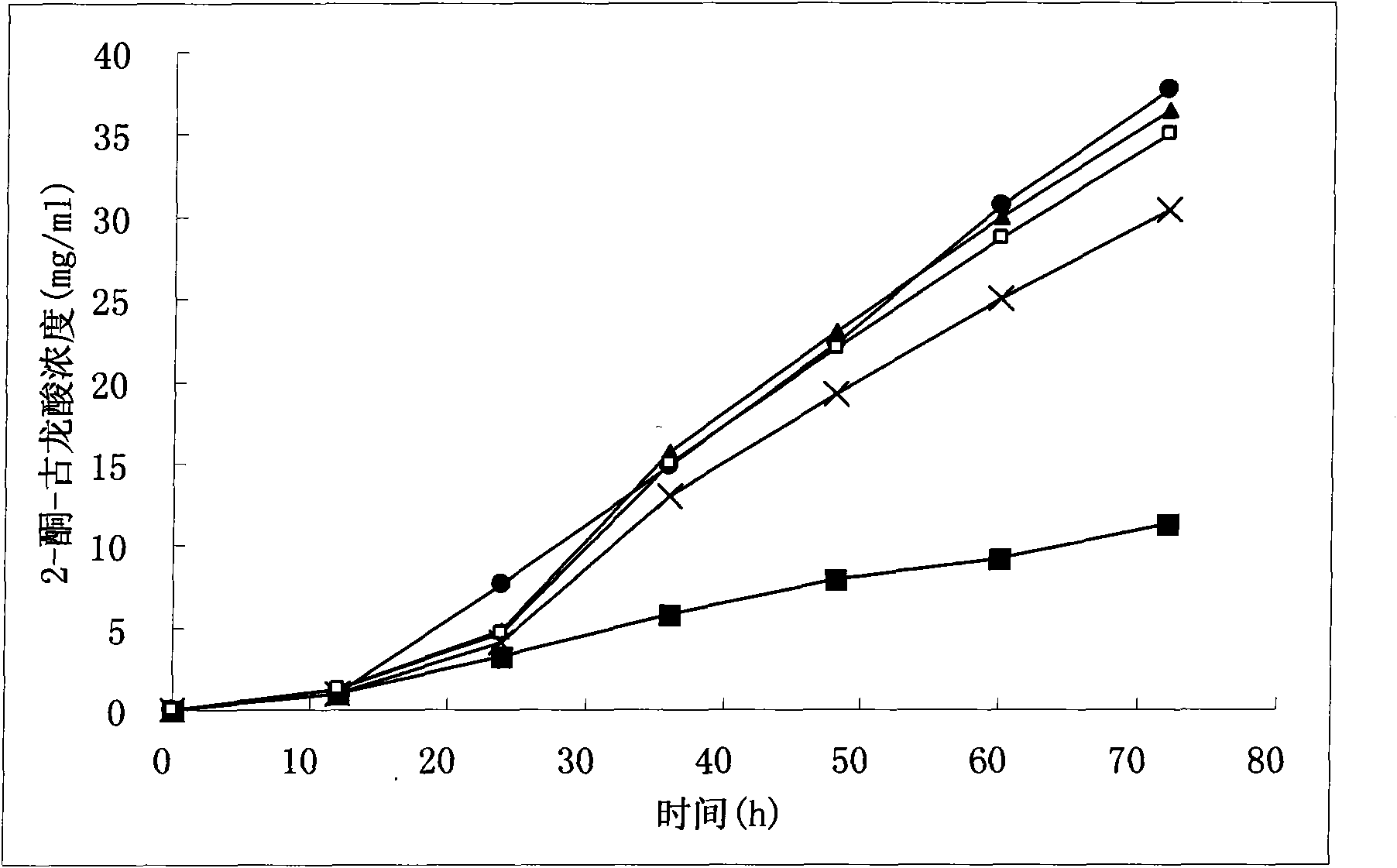

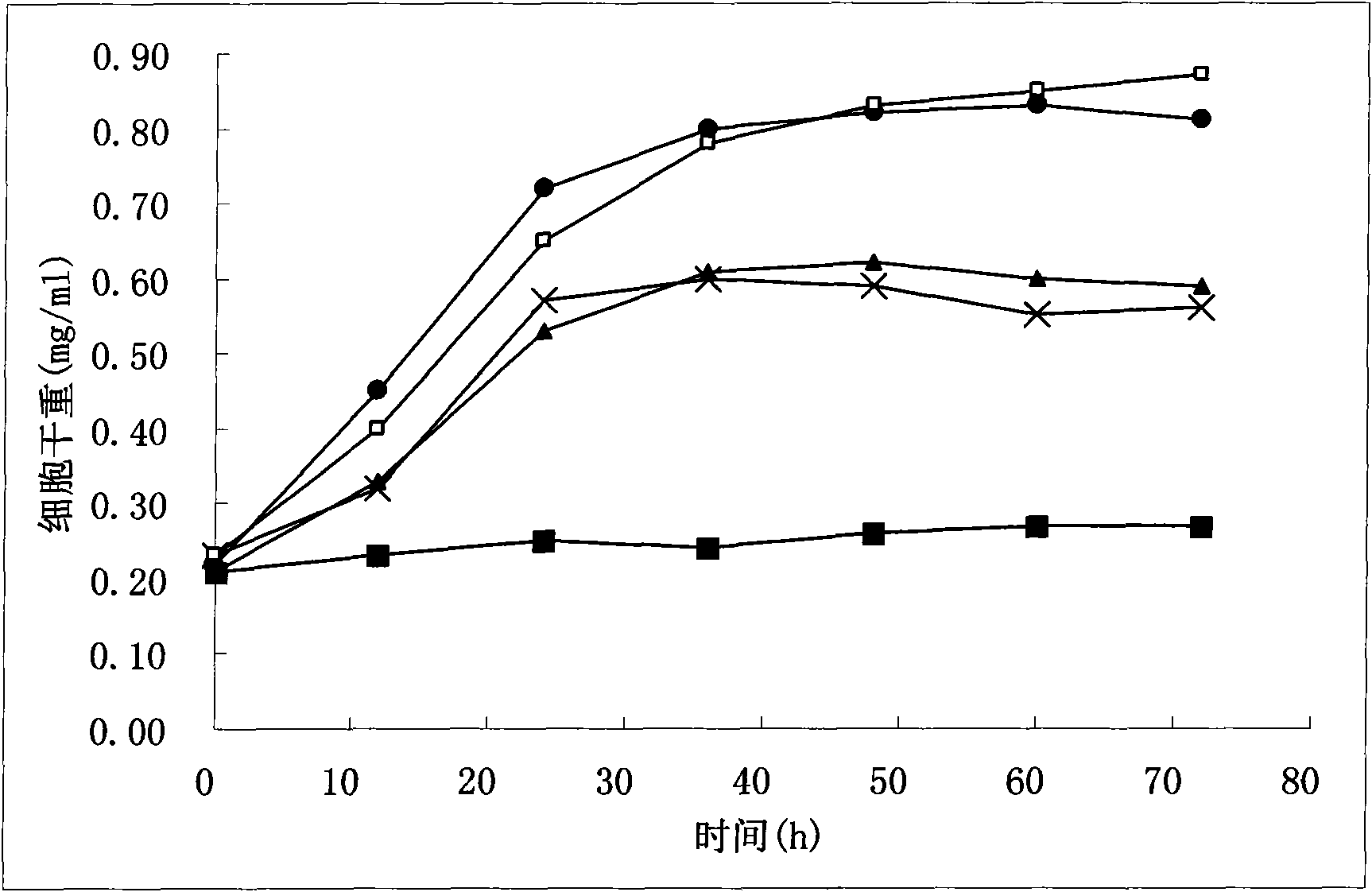

[0037] The seed culture solution was inserted into the fermentation medium at a ratio of 10% by vol...

Embodiment 2

[0040] The method for improving the production of 2-keto-L-gulonic acid by Gluconobacter oxydans comprises the following steps:

[0041] (1) Seed cultivation:

[0042] Weigh: L-sorbose 10g, corn steep liquor 2g, beef extract 2g, yeast extract powder 2g, urea 0.5g, peptone 2g, KH 2 PO 4 0.5g, MgSO 4 0.1g, CaCO 3 Add 0.5 g of water to 1 L, adjust the pH to 7.0, and sterilize at 121°C for 20 minutes to make a seed medium;

[0043] Inoculate Gluconobacter oxydans (Gluconobacter oxydans) CGMCC NO.1.110 on the slant into the seed medium, shake at 28°C and 160r / min on a shaker, and cultivate for 48 hours to prepare a seed culture solution;

[0044] (2) Fermentation:

[0045] Weighing: L-sorbose 40g, corn steep liquor 10g, urea 10g, KH 2 PO 4 0.5g, MgSO 4 0.2g, CaCO 3 Add 1 g of water to 1 L, adjust the pH to 7.5, and sterilize at 121°C for 20 minutes to make a fermentation medium;

[0046] The seed culture solution was inserted into the fermentation medium at a ratio of 5% ...

Embodiment 3

[0049] The method for improving the production of 2-keto-L-gulonic acid by Gluconobacter oxydans comprises the following steps:

[0050] (1) Seed cultivation:

[0051] Weighing: 50g of L-sorbose, 10g of corn steep liquor, 10g of beef extract, 10g of yeast extract powder, 5g of urea, 10g of peptone, KH 2 PO 4 5g, MgSO 4 0.7g, CaCO 3 Add 5 g of water to 1 L, adjust the pH to 6.5, and sterilize at 121°C for 20 minutes to make a seed medium;

[0052] Inoculate Gluconobacter oxydans (Gluconobacter oxydans) CGMCC NO.1.110 on the slant into the seed medium, shake at 35°C and 250r / min on a shaker, and cultivate for 24 hours to prepare a seed culture solution;

[0053] (2) Fermentation:

[0054] Weighing: L-sorbose 120g, corn steep liquor 50g, urea 25g, KH 2 PO 4 3g, MgSO 4 1.2g, CaCO 3 Add 10g of water to 1L, adjust the pH to 6.5, and sterilize at 121°C for 20 minutes to make a fermentation medium;

[0055] The seed culture solution was inserted into the fermentation medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com