Patents

Literature

71 results about "2-keto-L-gulonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

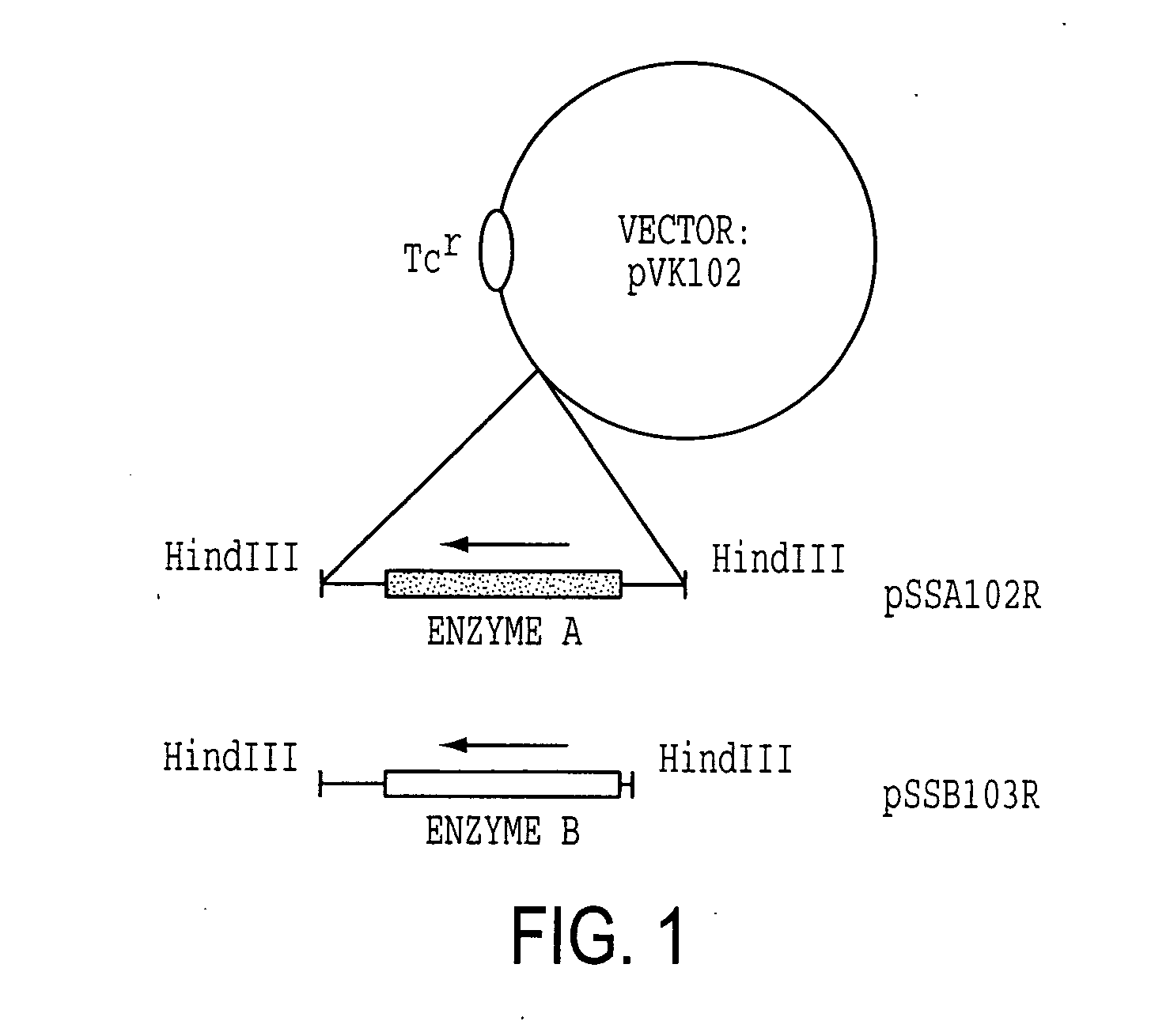

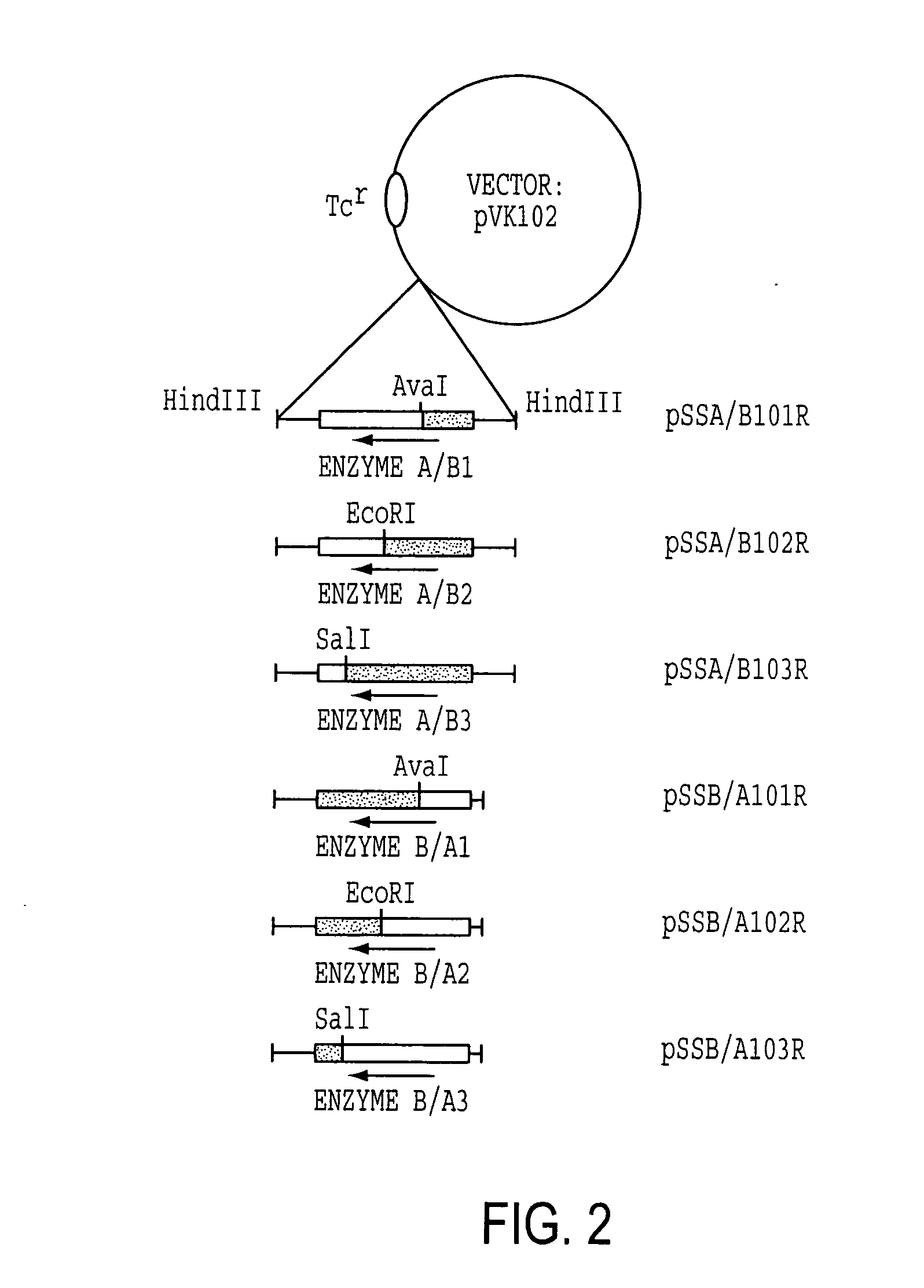

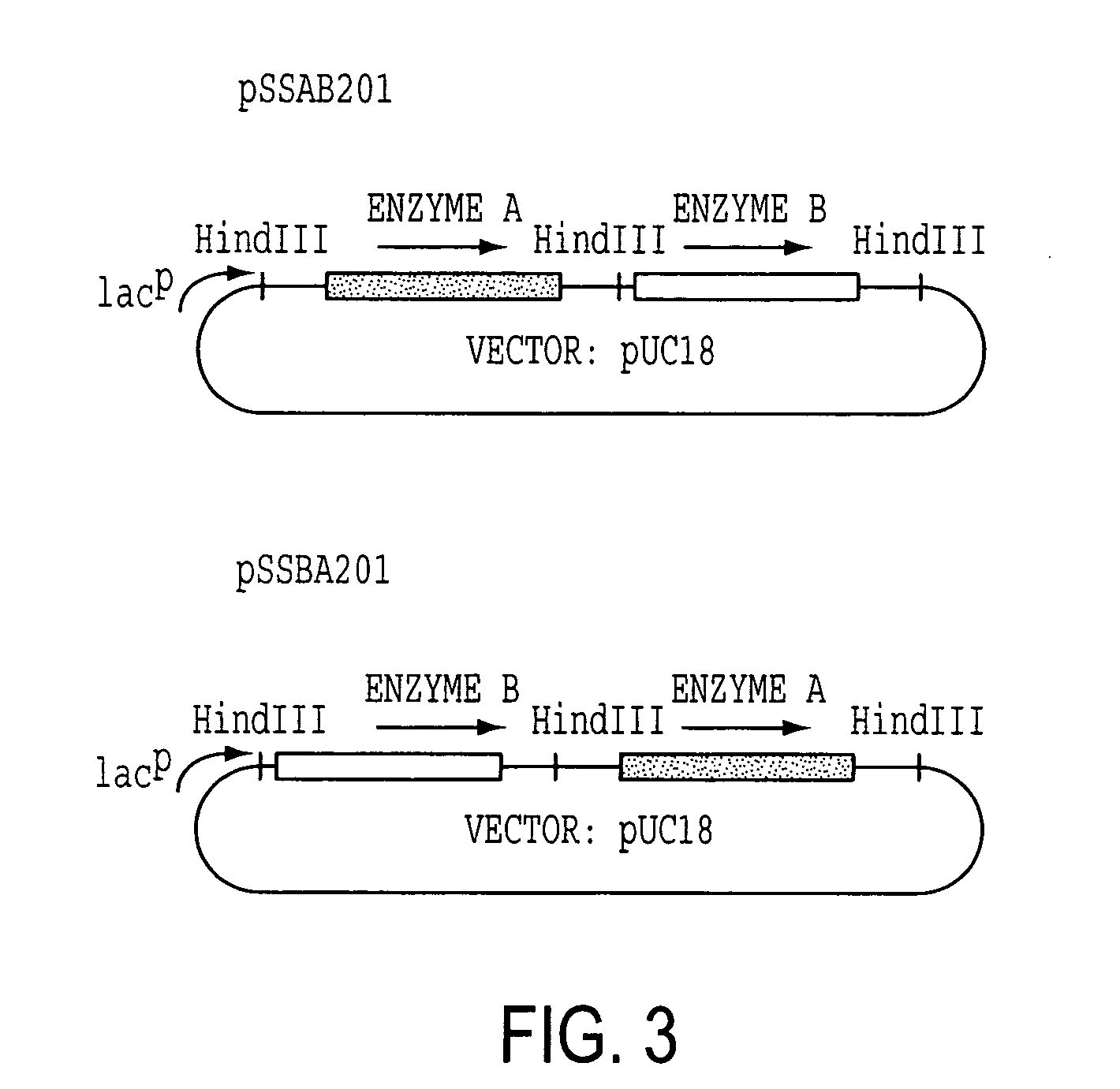

Novel alcohol/aldehyde dehydrogenases

The present invention is directed to a recombinant enzymes having alcohol and aldehyde dehydrogenase activity which comprises one or more recombinant polypeptides selected from the group consisting of polypeptides which are identified by SEQ ID NO 5, SEQ ID NO 6, SEQ ID NO 7, SEQ ID NO 8 and chimeric recombinant polypeptides that are a chimeric combination of at least two of the following amino acid sequences identified by SEQ ID NO 5, SEQ ID NO 6, SEQ ID NO 7, SEQ ID NO 8 and functional derivatives of the polypeptides identified above which contain addition, insertion, deletion and / or substitution of one or more amino acid residues, wherein said enzymatic polypeptides have said alcohol and aldehyde dehydrogenase activity. DNA molecules encoding the recombinant polypeptides, vectors comprising such DNA molecules, host cells transformed by such vectors and processes for the production of such recombinant enzymes are provided. Furthermore, the recombinant enzymes having alcohol and aldehyde dehydrogenase activity are used for obtaining aldehydes, ketones or carboxylic acids, and specifically, 2-keto-L-gulonic acid an intermediate for the production of L-ascorbic acid (vitamin C).

Owner:ROCHE VITAMINS INC

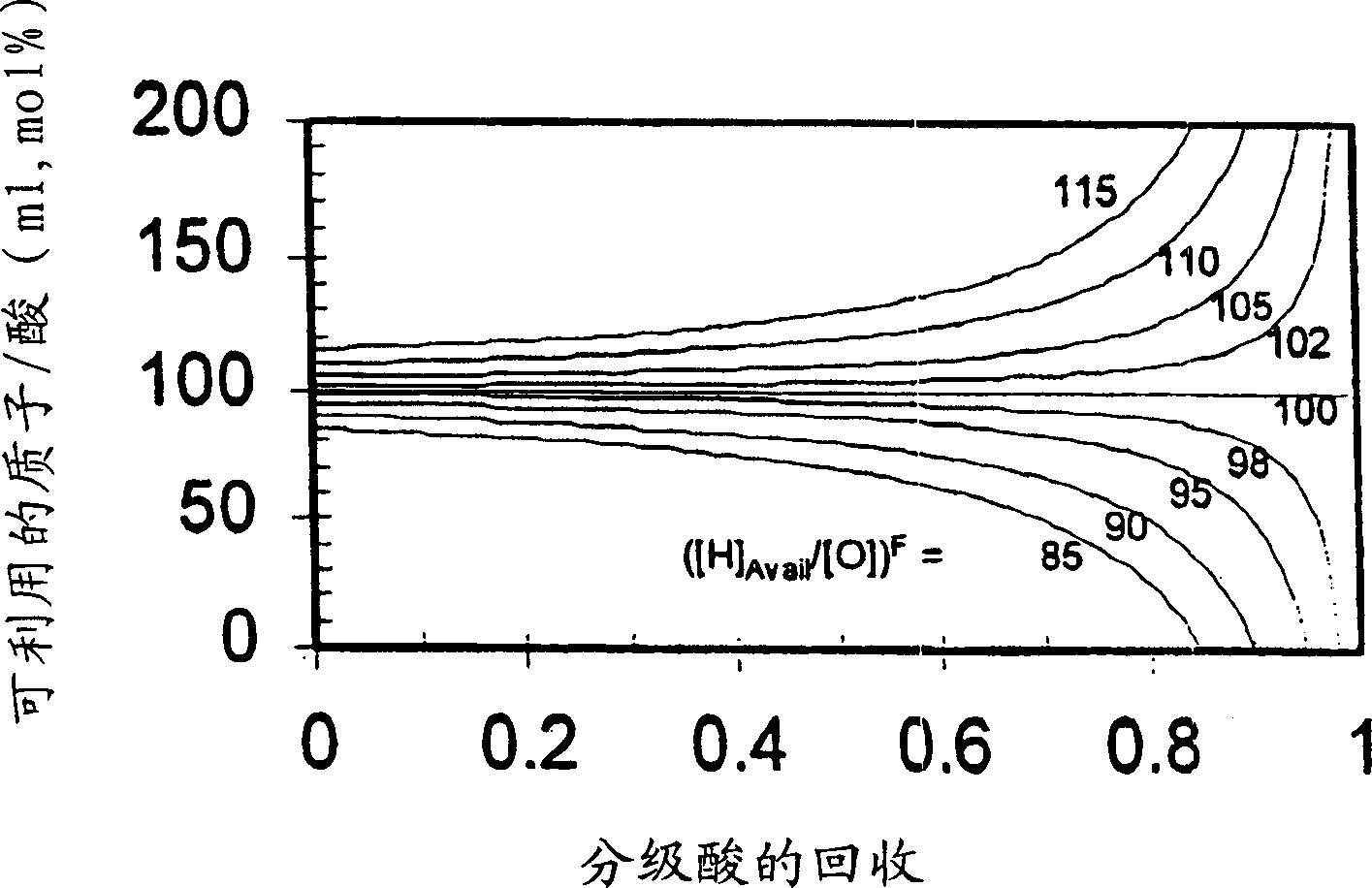

Process for recovery of organic acids from aqueous solutions

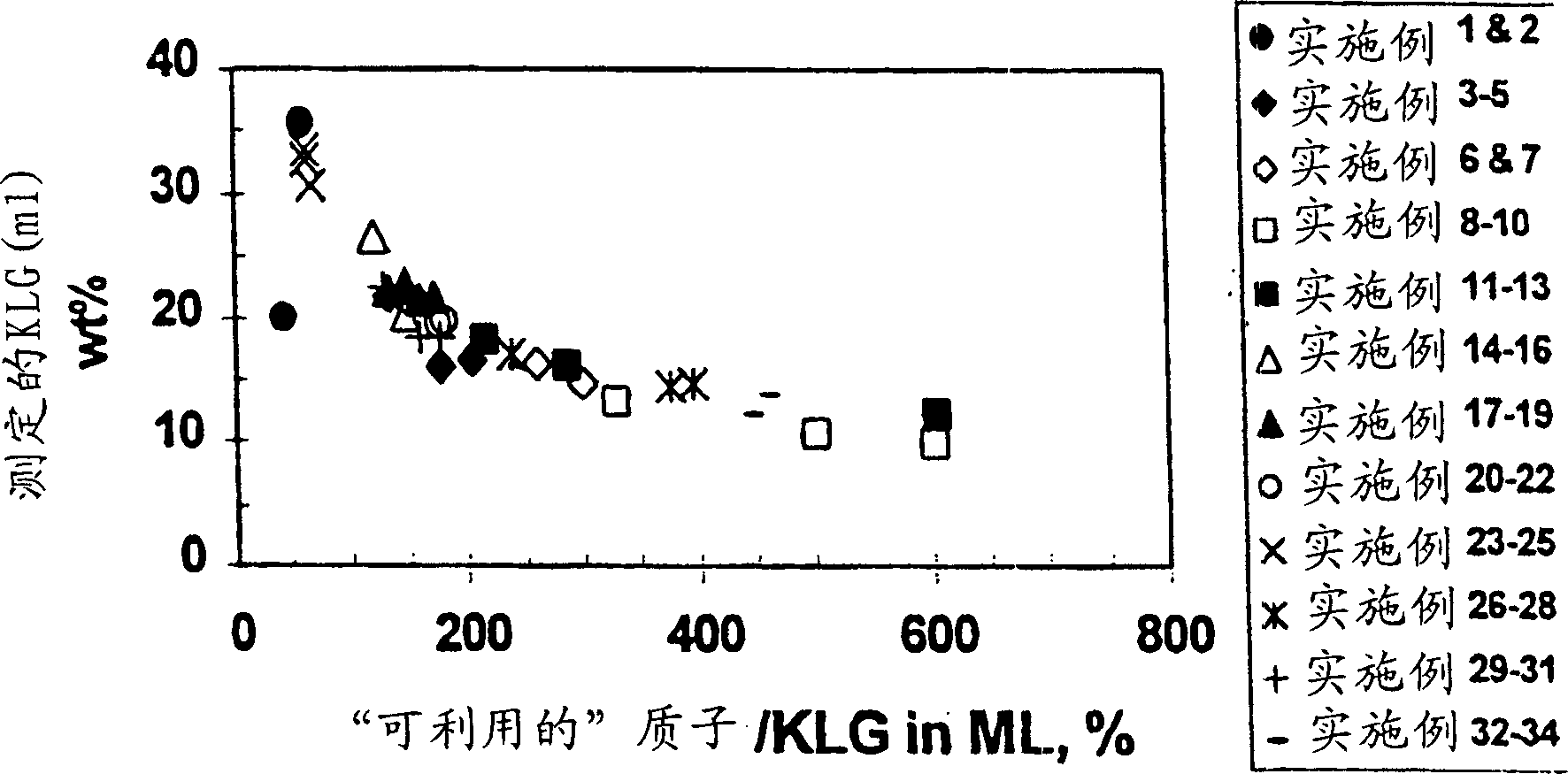

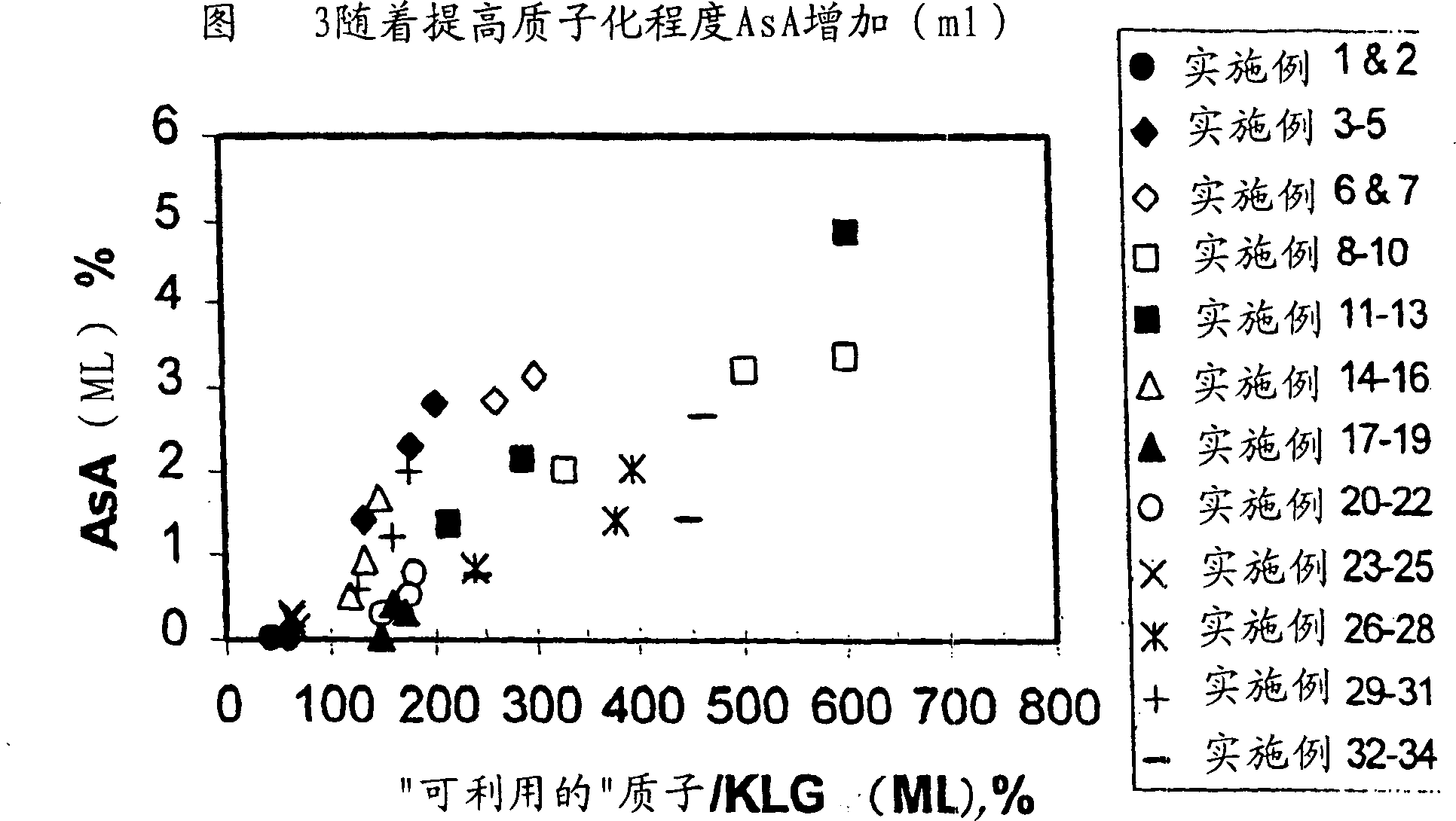

A process for recovering a desired organic acid from a solution includes the steps of: providing an aqueous solution including at least one desired organic acid or its acid anion; adjusting the proton concentration in the aqueous solution to a desired level, with the desired proton concentration being selected, at least in part, by the amount of available protons needed to associate with the acid anions of the desired organic acid(s) to be recovered and / or acid anions that are weaker than the desired organic acids; and recovering at least a portion of the at least one desired organic acid from the aqueous phase. The desired proton concentration can be based on the amount of available protons being greater than, less than or substantially equal, to the amount of protons needed to associate with the anion of the desired organic acid(s) and acid anions that are weaker than the desired organic acid(s).Specific examples of suitable organic acids include, but are not limited to, ascorbic, succinic, tartaric, glyconic, gulonic, citric, lactic, hialic, maleic, acetic, formic, gluconic pyruvic, propionic, butyric, itaconic acids and mixtures thereof. One embodiment of the present invention relates to the recovery of 2-keto-L-gulonic acid (KLG) from aqueous solutions such as fermentation baths.

Owner:EASTMAN CHEM CO

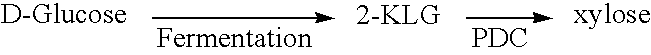

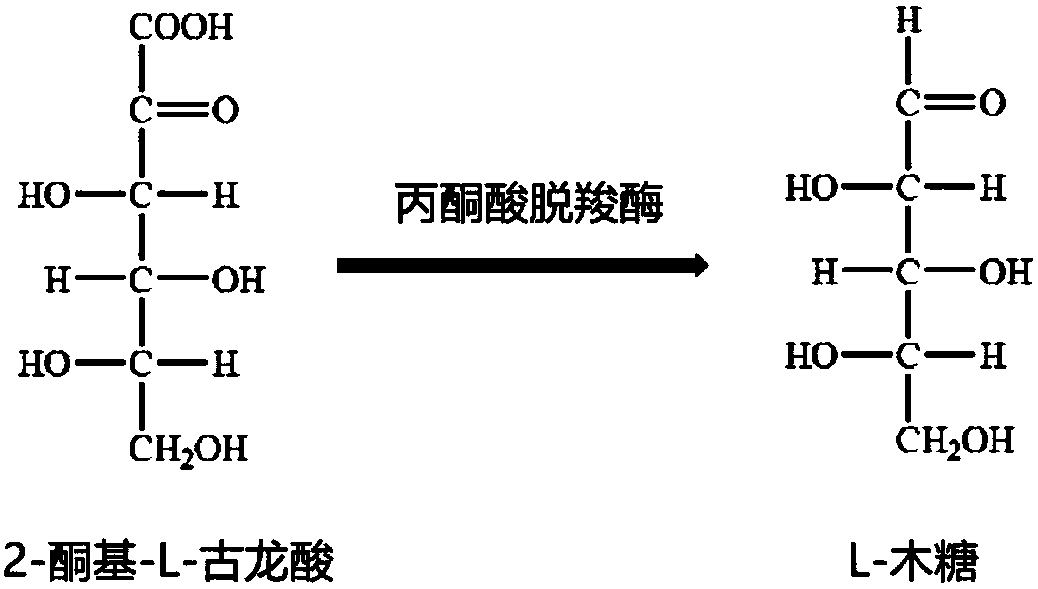

Enzymatic decarboxylation of 2-keto-L-gulonic acid to produce xylose

ActiveUS20050239174A1Increase valuePrepared cost-effectivelyMicrobiological testing/measurementBiofuelsIn vivo2-keto-L-gulonic acid

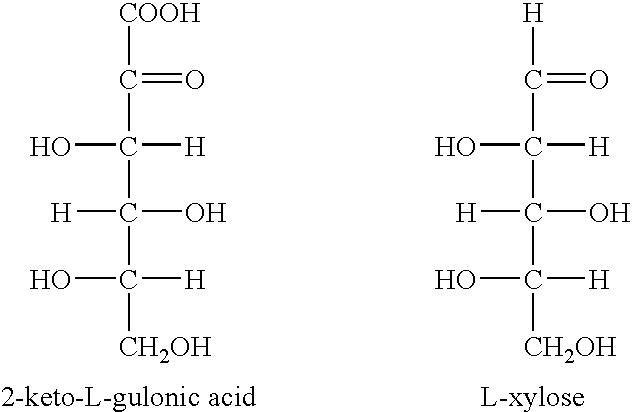

The invention is drawn to the enzymatic decarboxylation of 2-keto-L-gulonic acid (2-KLG) to produce xylose. The invention is also drawn to a method to detect xylose in vitro or in vivo (intracellularly), which employs an L-xylose dehydrogenase.

Owner:ARCHER DANIELS MIDLAND CO

Method for improving gluconobacter oxydans to produce 2-keto-L-gulonic acid

ActiveCN101603060ALow costReduce pollutionMicroorganism based processesFermentationBacillus megateriumGluconic acid

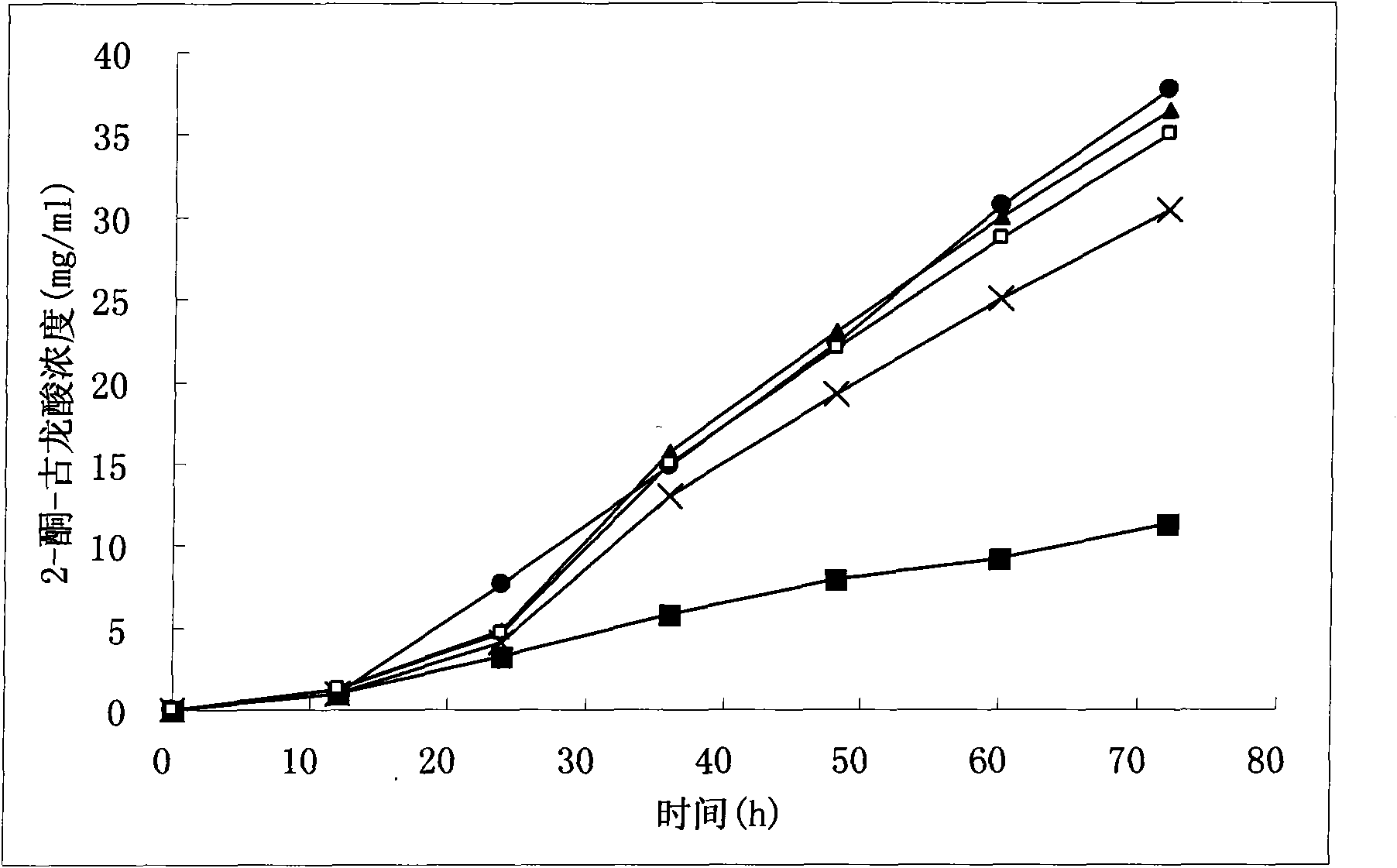

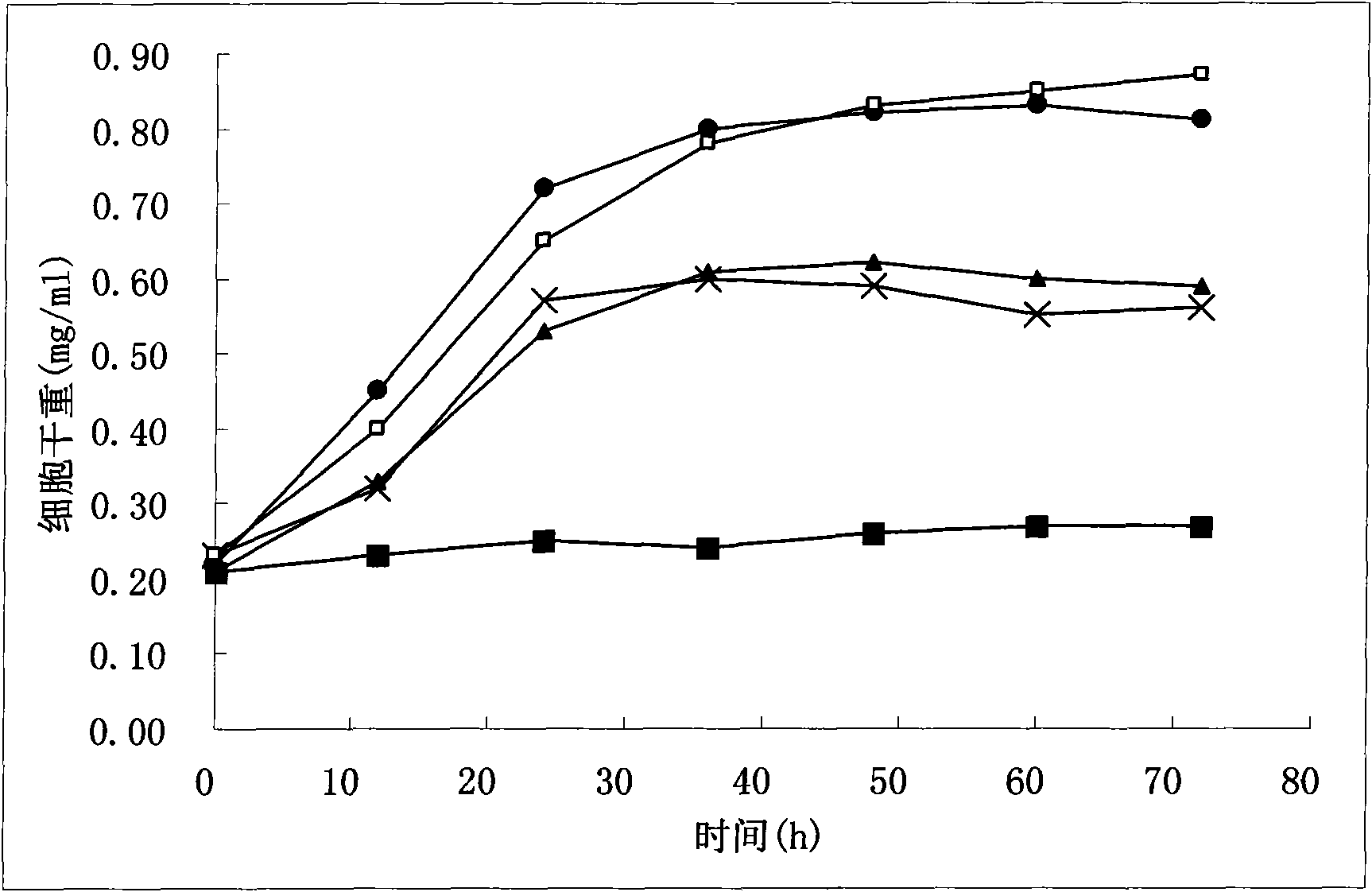

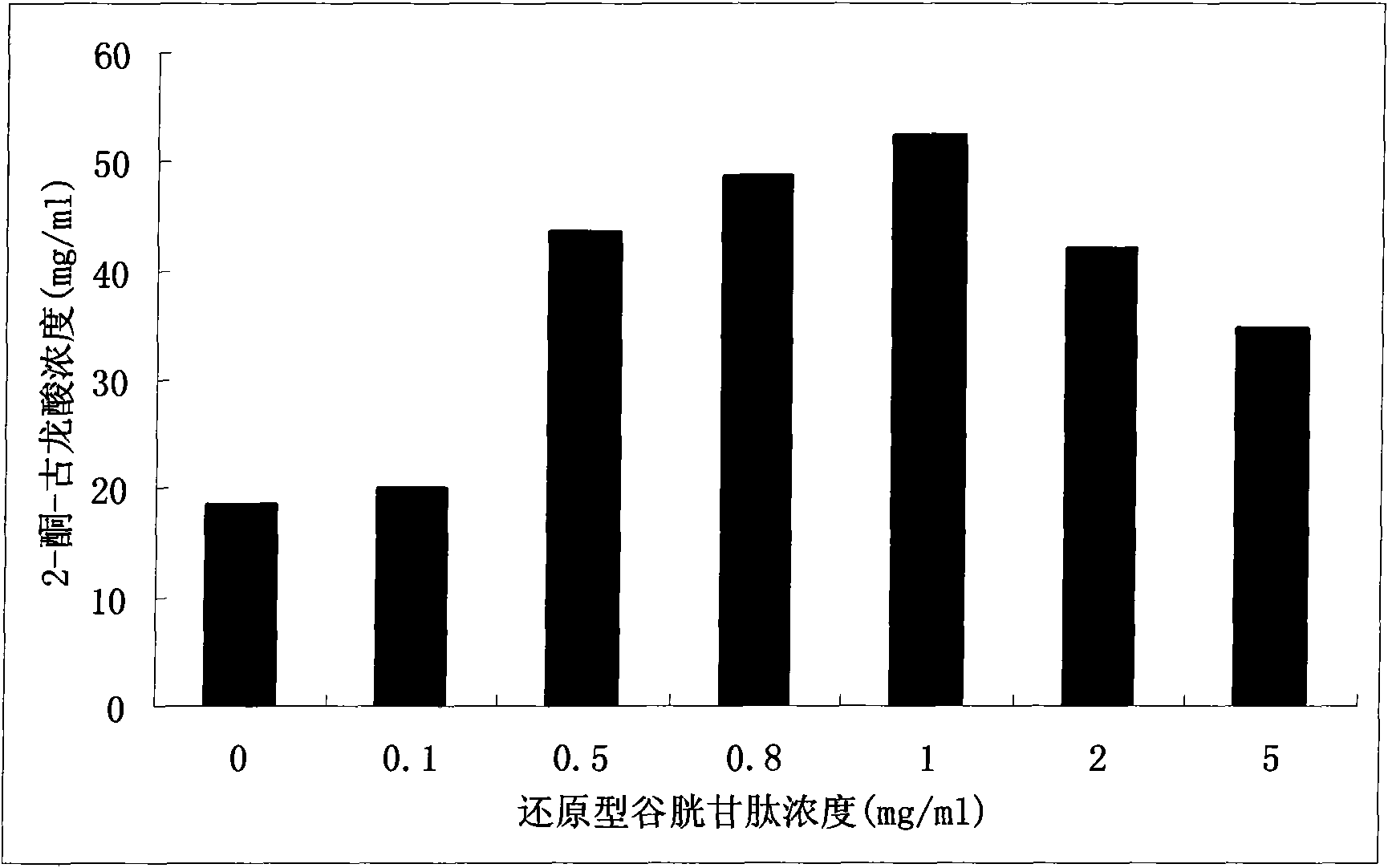

The invention discloses a method for improving gluconobacter oxydans to produce 2-keto-L-gulonic acid, which comprises the following steps: (1) seed culture, namely inoculating bevel gluconobacter oxydans into a seed culture medium to form seed culture solution; and (2) fermentation, namely inoculating the seed culture solution into a fermentation culture medium, oscillating the mixture in a shaking bed, carrying out fermentation culture for 48 to 96 hours, and adding a sulfhydryl compound into the mixture at any moment of the fermentation culture in a range of 0 to 36 hours to make the final concentration of sulfhydryl between 0.1 and 30mM. The method can improve the growth speed of the gluconobacter oxydans and the efficiency for producing the 2-keto-L-gulonic acid, and achieve the aim of partially replacing the companion effect of companion fungus so as to reduce the using amount of bacillus megaterium of the companion fungus, reduce the cost of the culture medium and reduce the pollution.

Owner:TIANJIN UNIV

Method for producing 2-keto-l-gulonic acid

ActiveCN101736071ASolve the shortcomings of slow growth and slow acid productionOptimizing Growth CorrelationsMicroorganism based processesFermentationMicroorganismAnimal science

The invention provides a method for producing 2-keto-l-gulonic acid, including the following steps of: feeding nitrogen source nutrient solution from the 20th to the 26th hour in the fermentation process to compensate nutritional demands of microorganism growth in the fermentation process, finishing feeding solution in the 40th to the 45th hour, wherein the dissolved oxygen is controlled to be 30-50% in the nutrient solution feeding process. The invention utilizes a method of feeding nutrient solution at middle and later stages of fermentation, overcomes disadvantage that biomass grows and generates acid slowly, combines control of factors of temperature, pH, dissolved oxygen, low initial glucose, fed-batch glucose compensation and the like, and optimizes the growth relations of biomasses with different sizes in microbial mixed fermentation. The gulonic acid content of the invention is 105-115mg / ml, and the glucose acid convert ratio is 92-95%.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Preparation technology for 2-keto -L-gulonic acid ferment strain

ActiveCN101575588AHigh densityIncrease vitalityBacteriaMicroorganism based processesSucroseSaccharum

The invention discloses a preparation technology for 2-keto-L-gulonic acid ferment strain, adopting large and small bacteria for mixed culture, wherein, the small bacteria is ordinary ketogenic gulonic acid bacteria, and the large bacteria is Bacillus megatherium. The invention comprises the following steps: firstly, inoculating the small bacteria onto a slant culture medium to cultivate for 16 to 48 hours separately; then, inoculating the large bacteria and continuing to cultivate for 24 to 72 hours with the quantity ratio between the large bacteria and the small bacteria being 1:(20-40); taking sucrose with the concentration of 5-30g / L or fructose with the concentration of 5-20g / L as the main carbon source in the culture medium; introducing the seed mixture of large and small bacteria into the culture medium for cultivation and controlling the bacteria count of seeding liquid to 10-10 / ml. The invention changes the proportion between large bacteria and small bacteria, increases the strain density, and improves the strain vitality, thus shortening the fermentation period; the invention is further characterized by unchanging strain, easy operation and widespread use.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

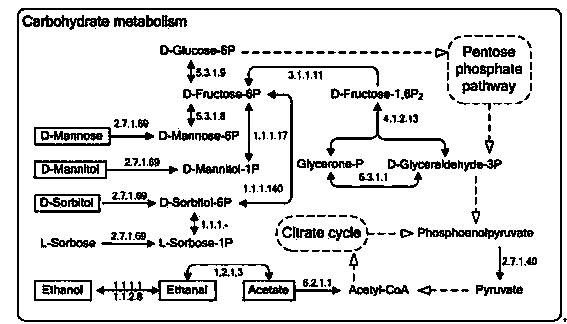

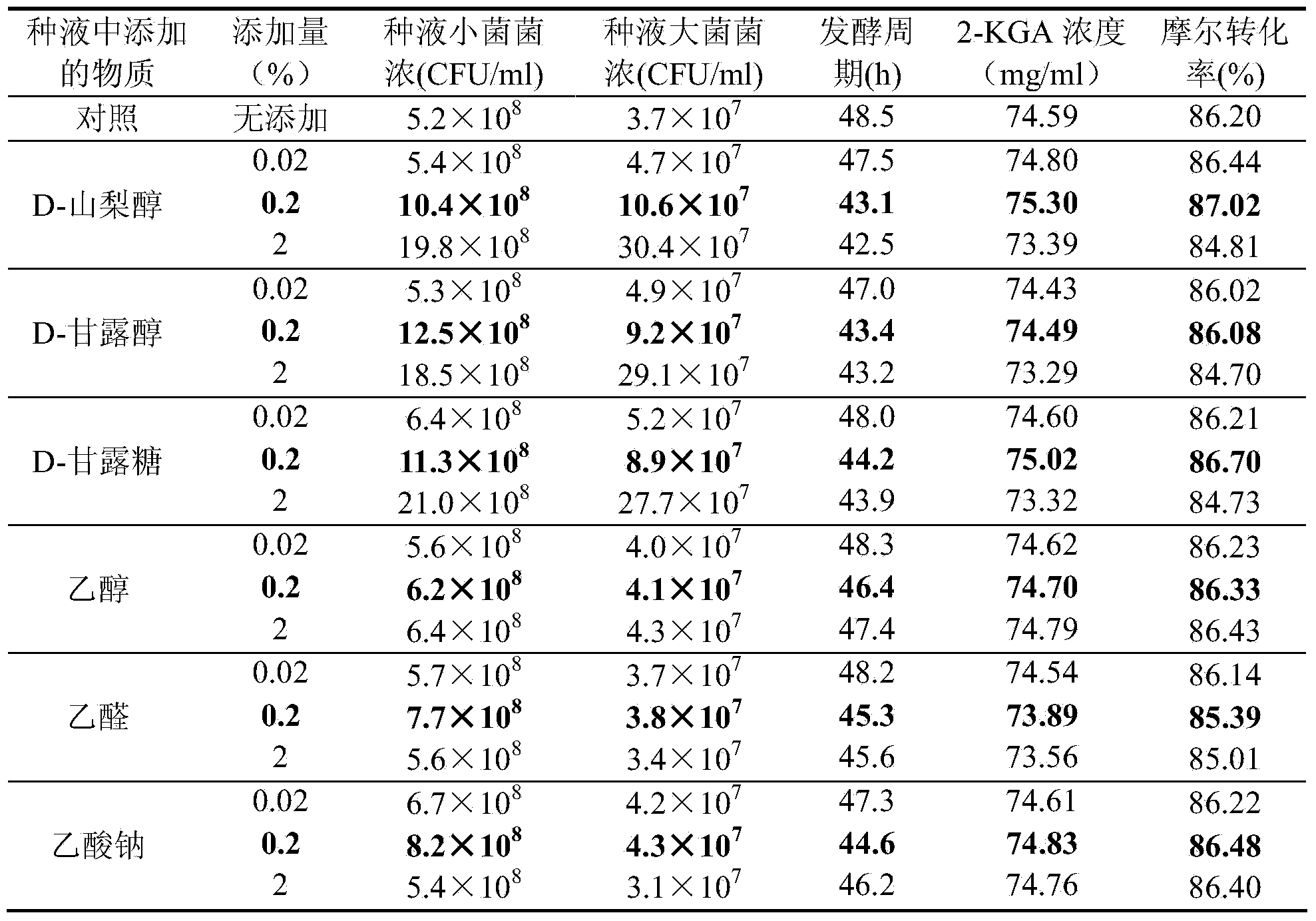

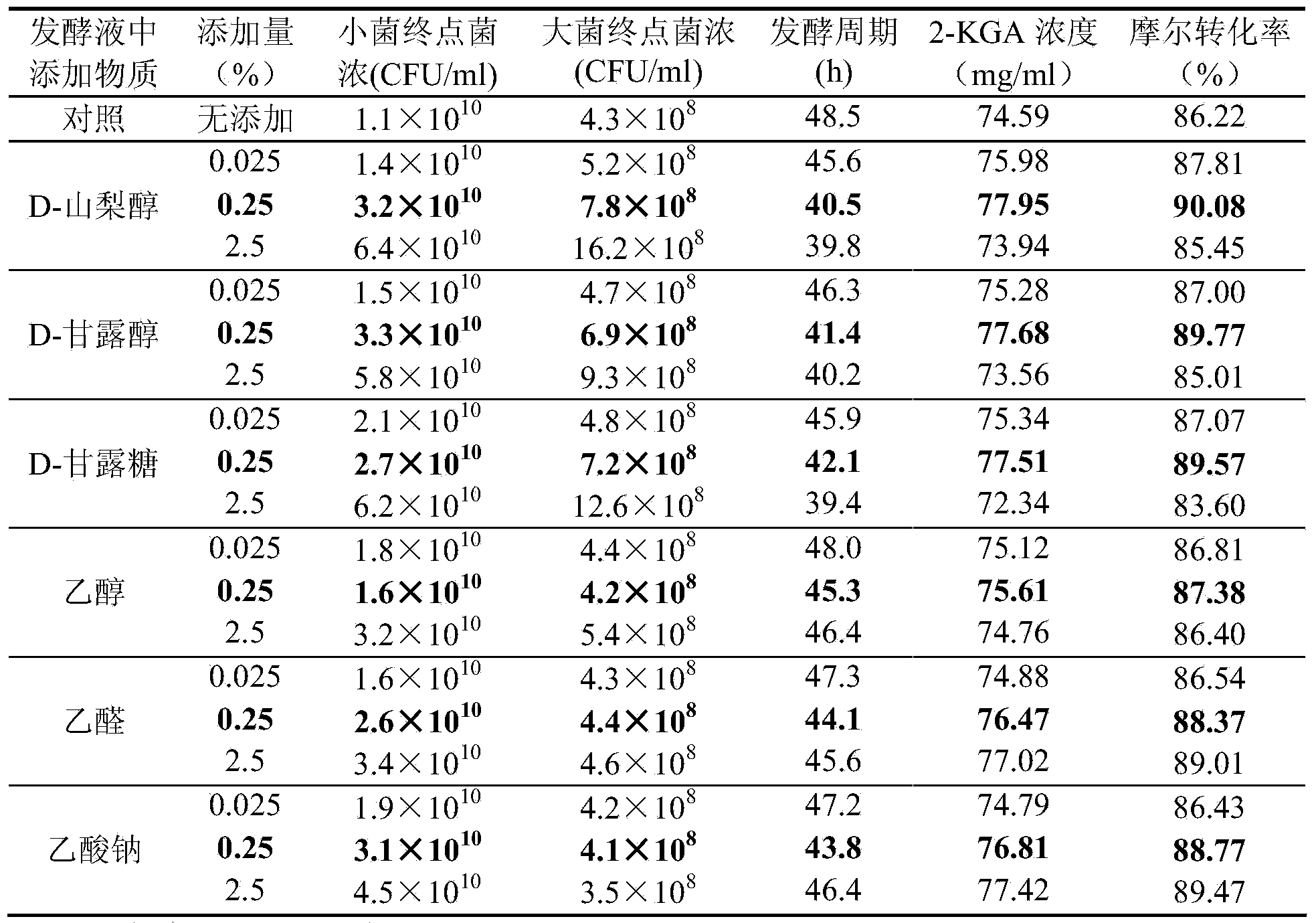

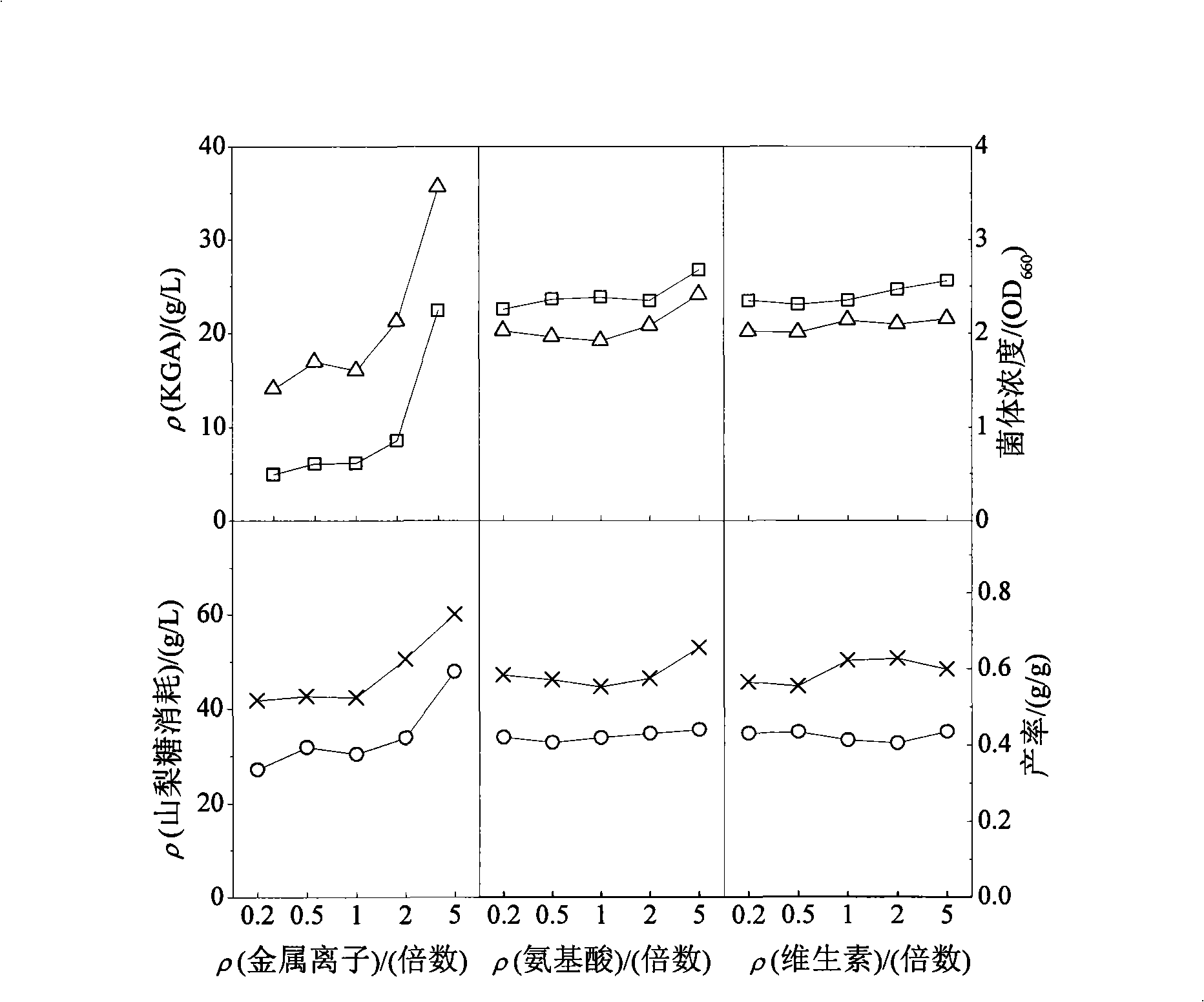

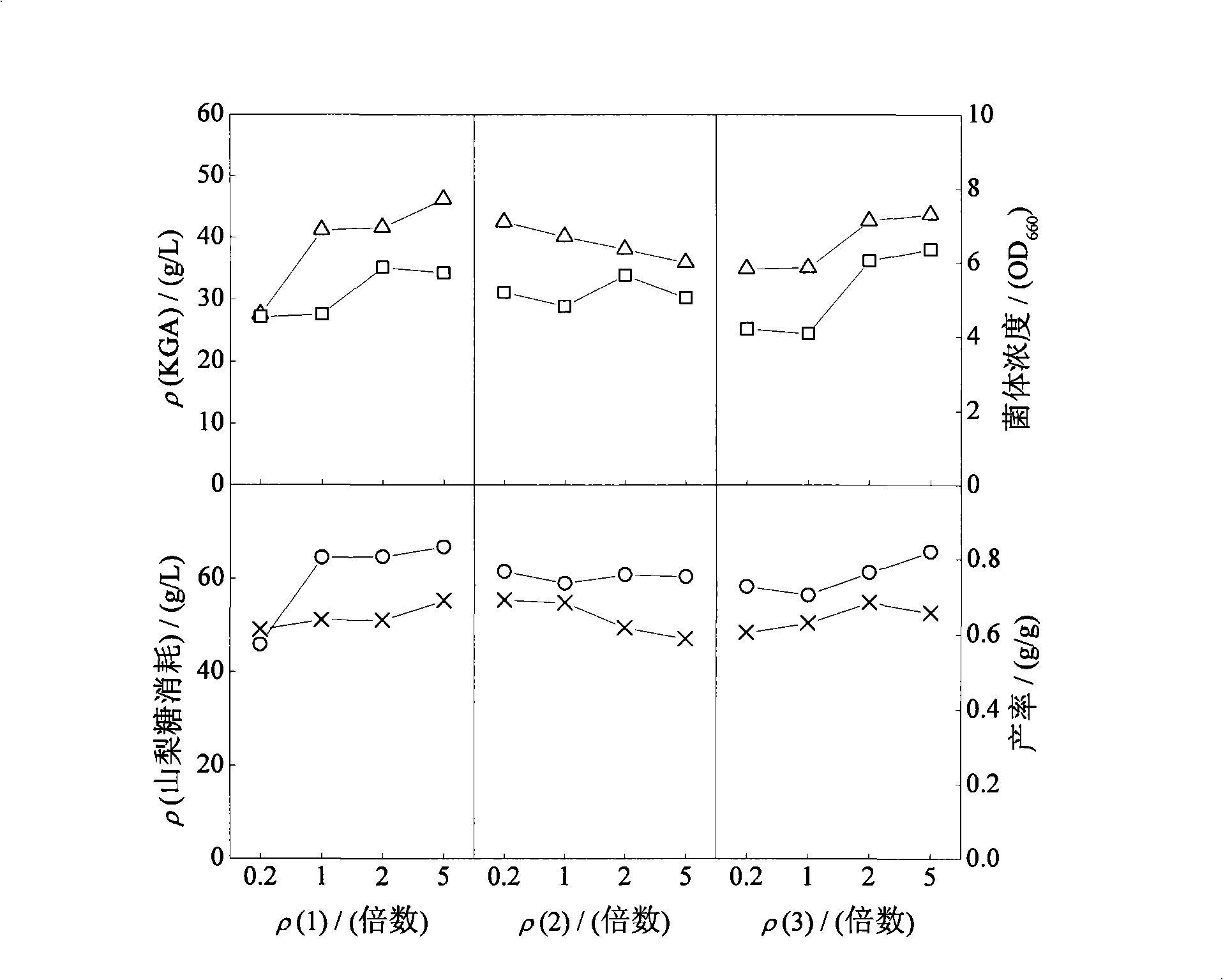

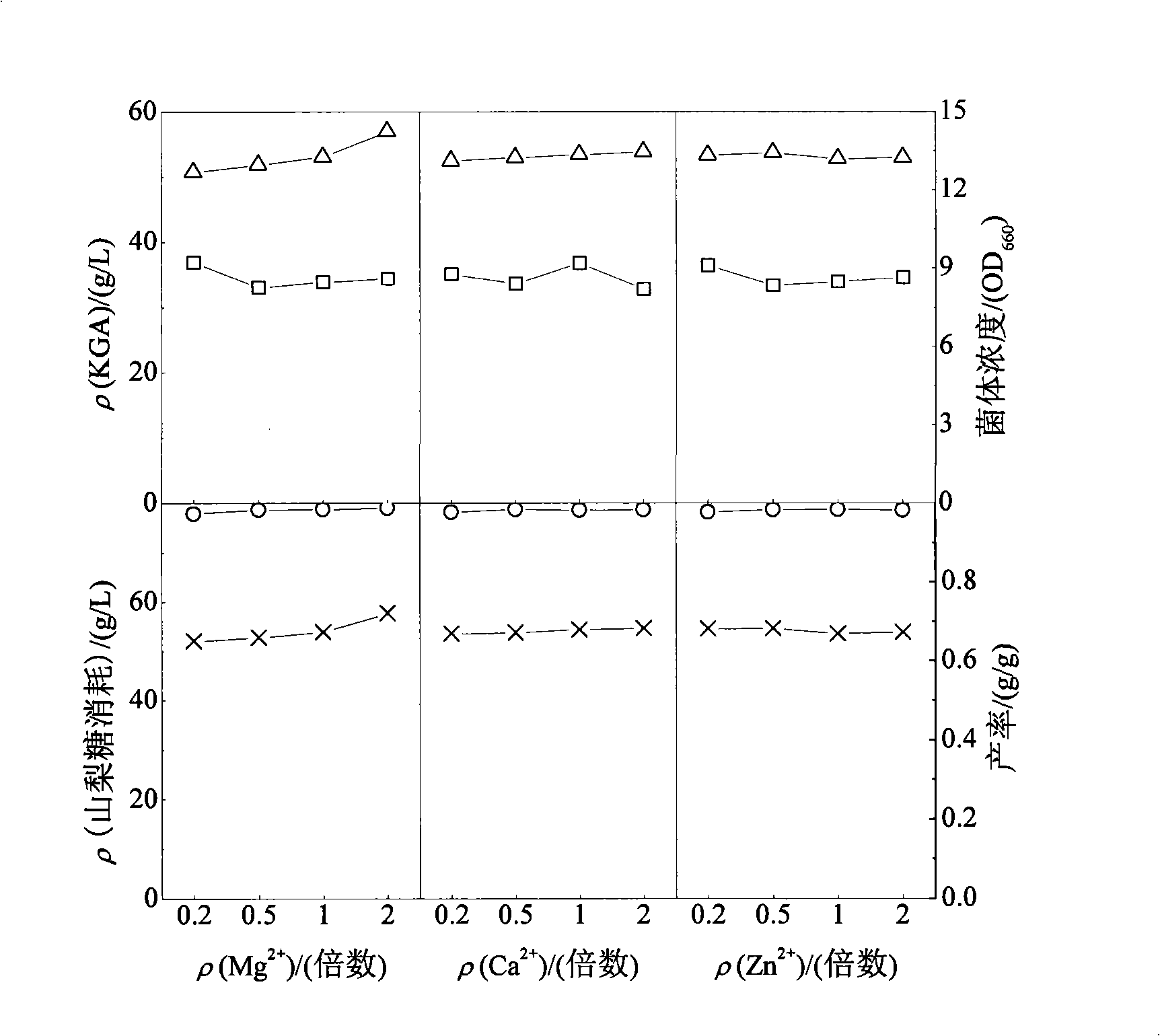

Method for improving production capacity of 2-KGA (2-keto-L-gulonic acid) through enhancement of Ketogulonogeniumvulgarum carbon metabolism level

InactiveCN104357529AIncrease profitPromote growthMicroorganism based processesFermentationCarbon metabolismVITAMIN C PREPARATIONS

The invention discloses a method which enhances glycometabolism efficiency of Ketogulonogeniumvulgarum, increases the number of bacteria, greatly shortens the incubation period of 2-KGA (2-keto-L-gulonic acid) and improves the production efficiency by adding carbon sources including two-carbon units such as ethyl alcohol, acetaldehyde and acetic acid as well as six-carbon units such as D-sorbitol, D-mannitol and D-mannose which facilitates utilization of Ketogulonogeniumvulgarum in a mixed fermentation process of a vitamin C two-step fermentation method according to research results of Ketogulonogeniumvulgarum metabolic network analysis. In a 5L fermentation tank, the period can be shortened by 14.04%, and the yield is increased by 3.40 %. According to another application, L-sorbose is taken as a carbon source by reducing Ketogulonogeniumvulgarum, so that the efficiency for converting L-sorbose into 2-KGA is also improved. According to the method, the production process is advanced, the raw material cost is low, and the method is suitable for large-scale industrial production and is improvement and promotion of vitamin C preparation technology with a biological fermentation method in about forty years of China; and besides, harmful substance emission in a production process is prevented, pollution and public hazard to the ambient environment are avoided, and environment protection requirements are met.

Owner:SHENYANG PHARMA UNIVERSITY

Method for enhancing fermentation and production stability of 2-ketone-L-Gulonic acid

InactiveCN101338335AIncrease productionHigh yieldMicroorganism based processesFermentationGluconic acidKetone

Owner:JIANGNAN UNIV

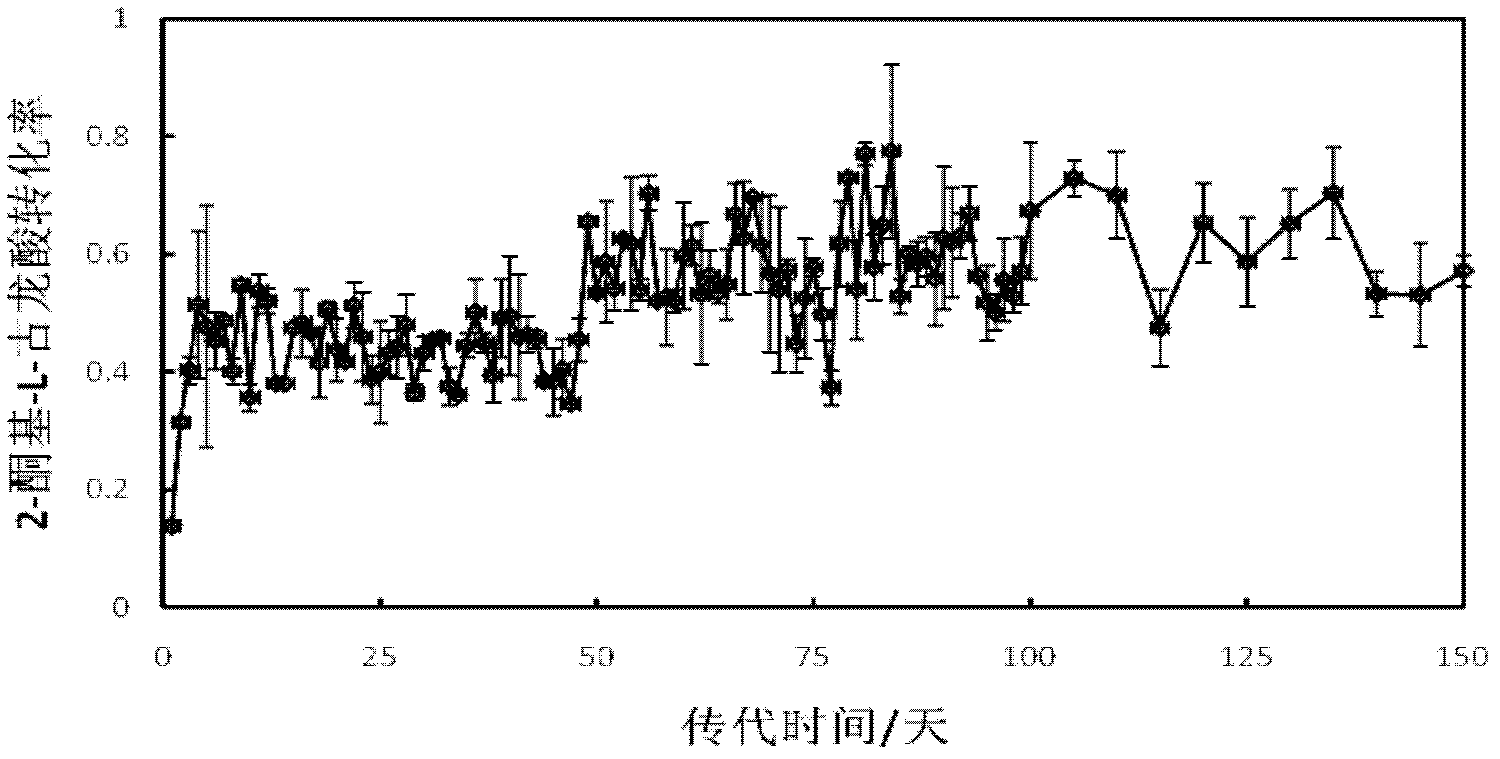

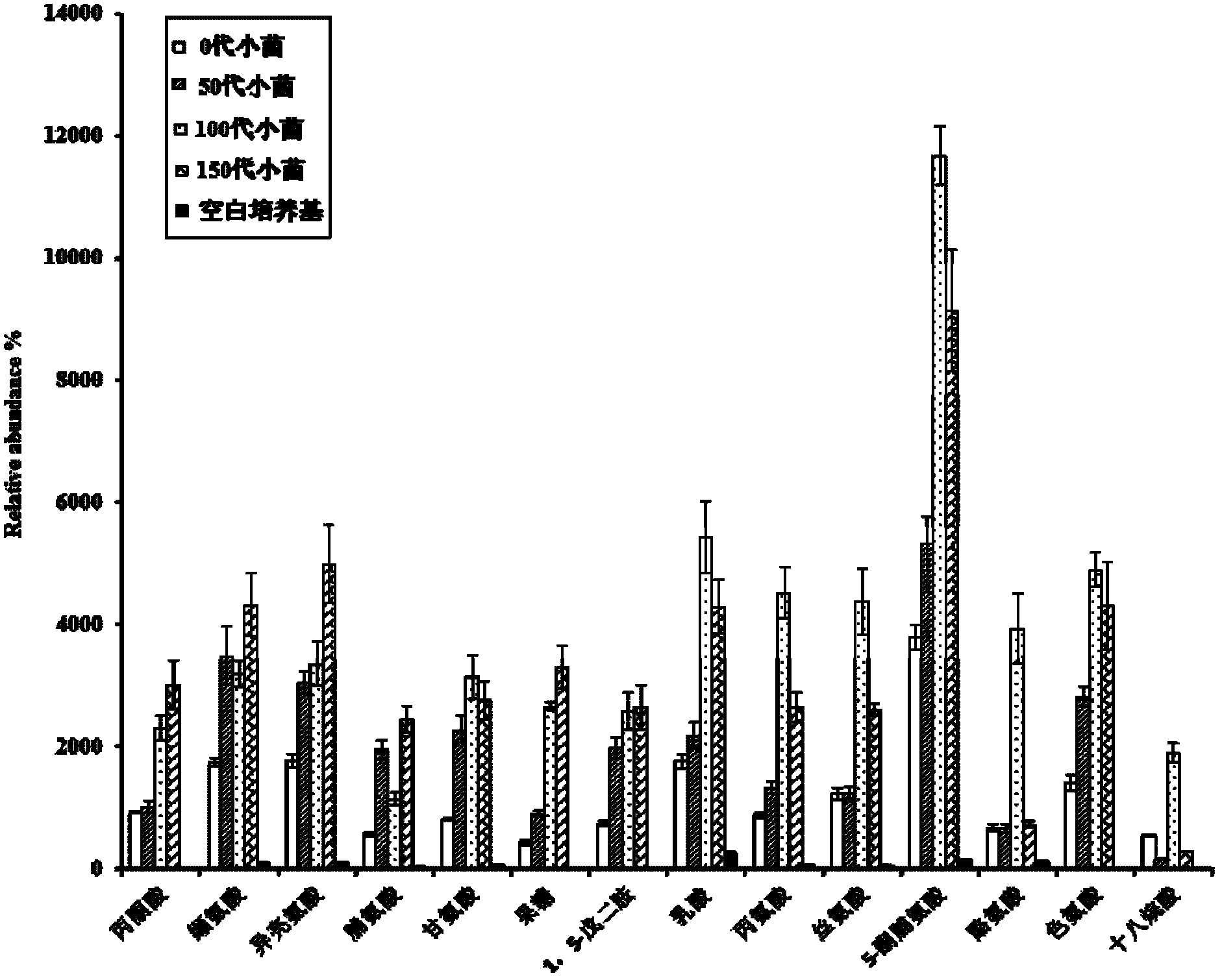

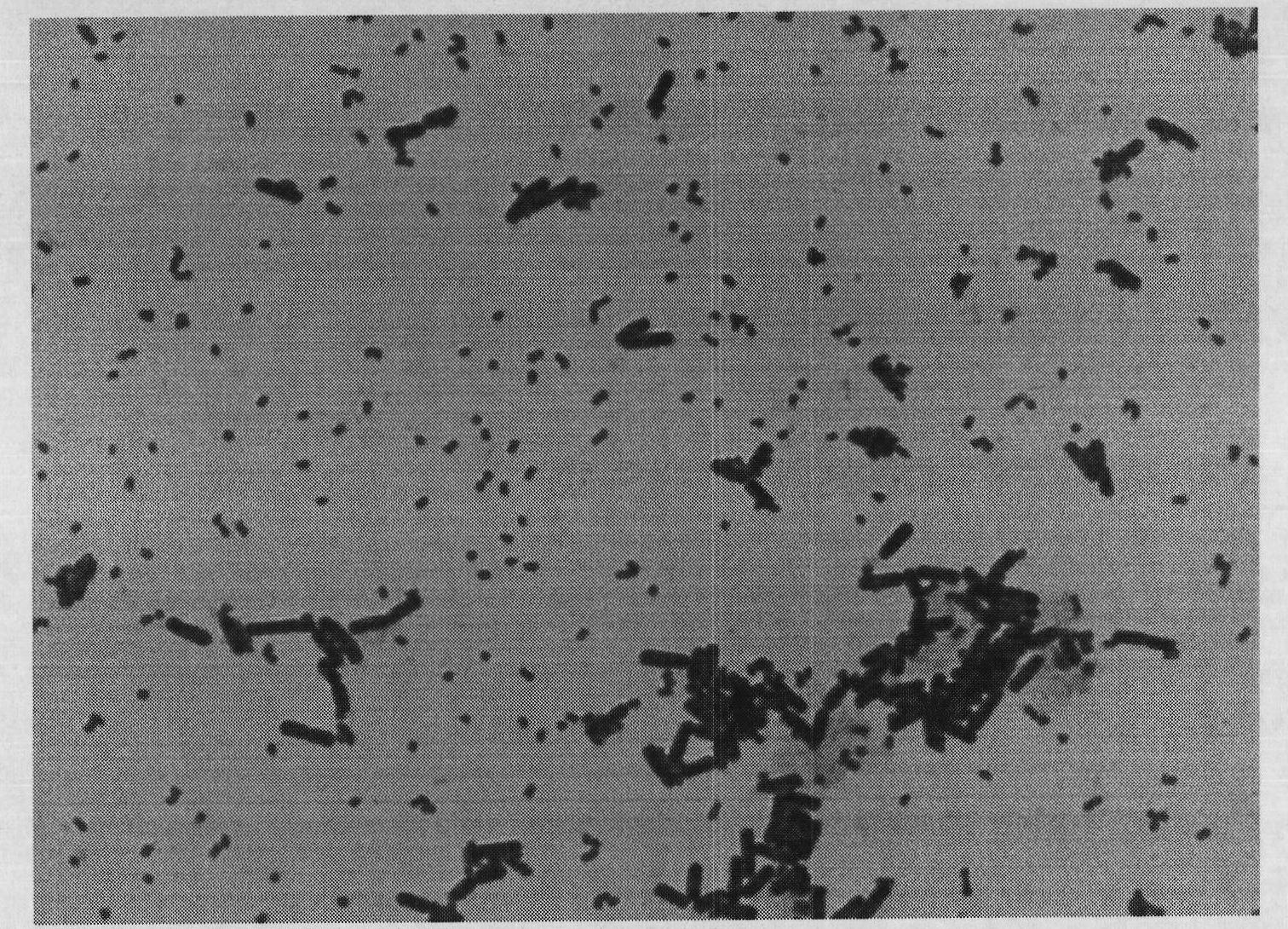

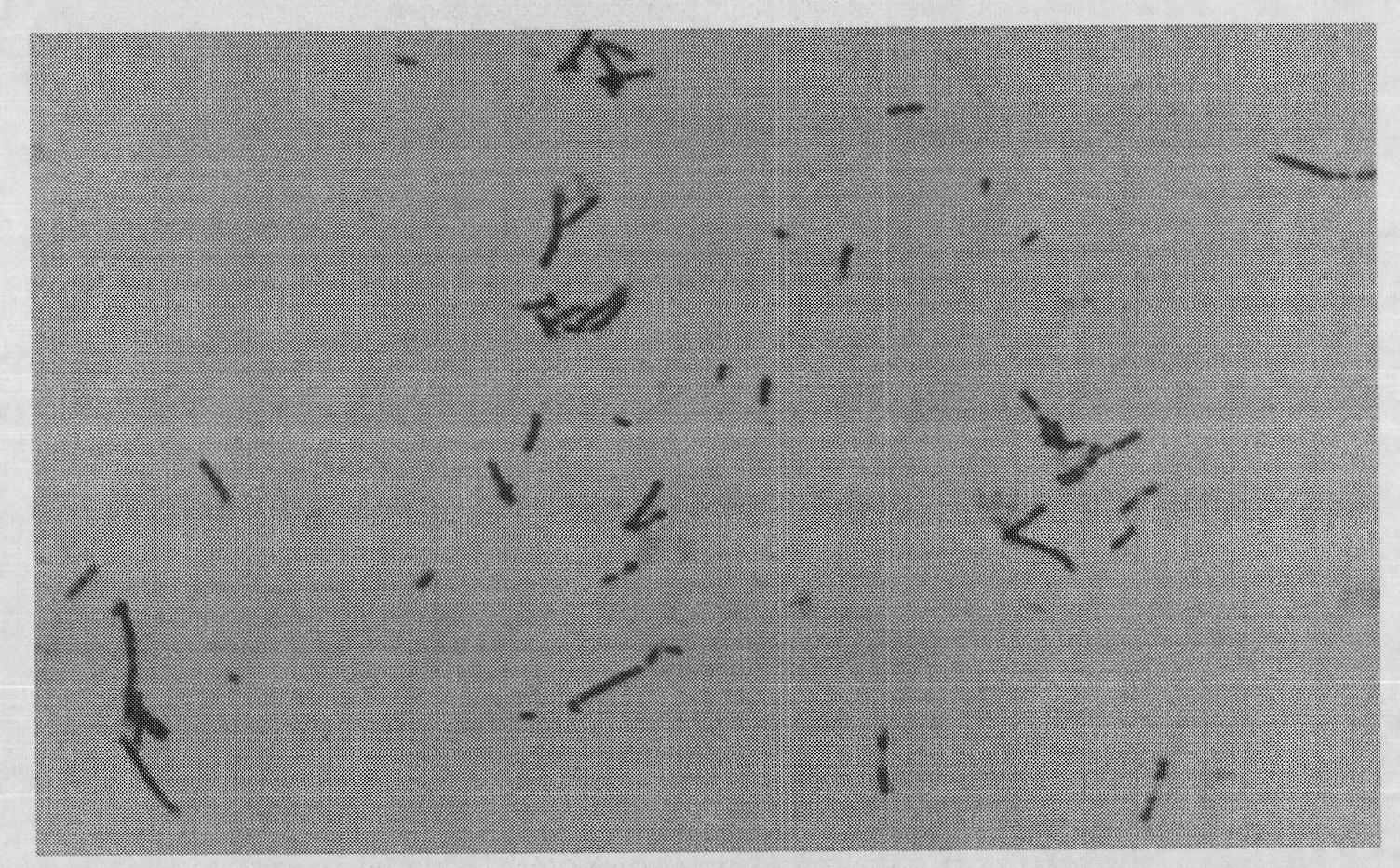

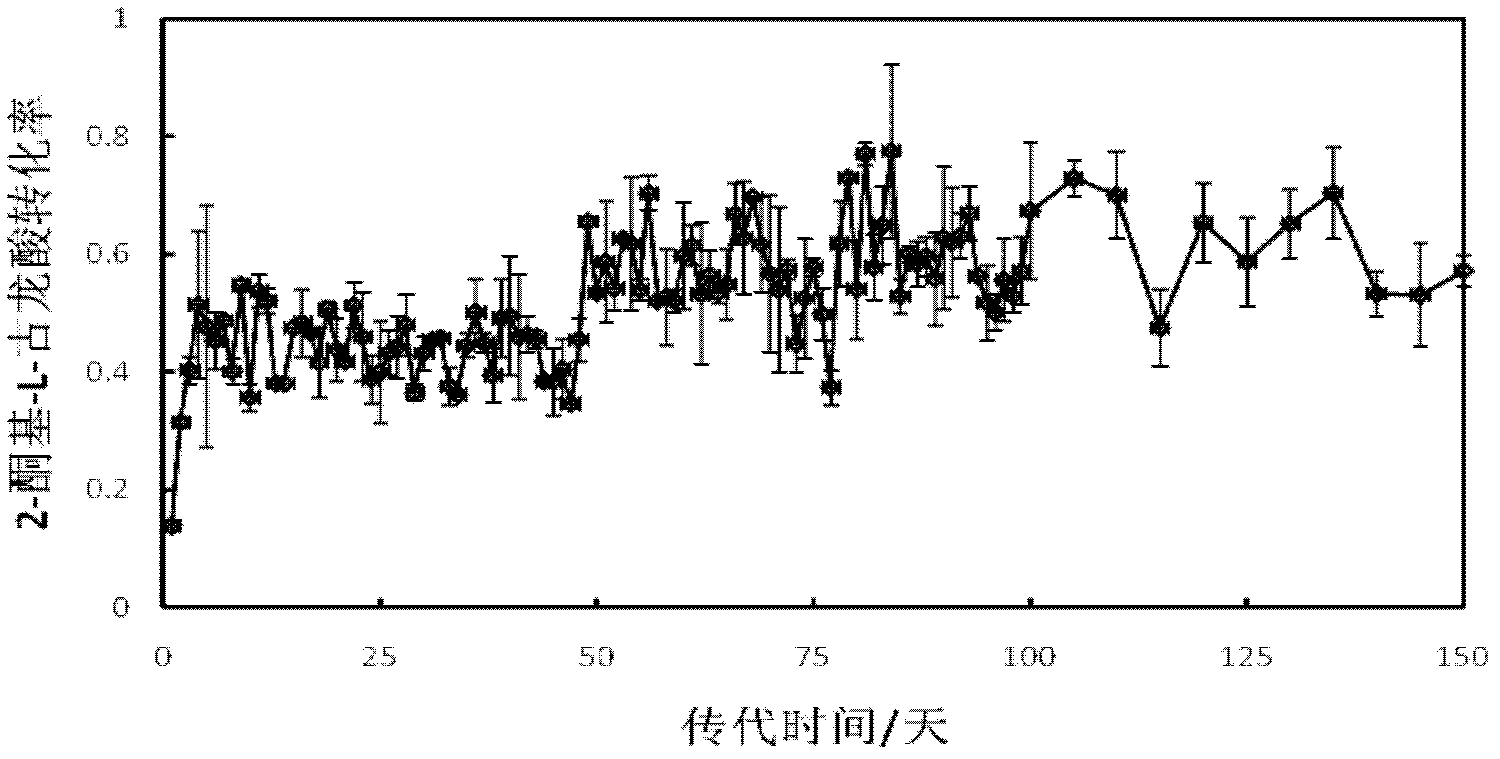

Method utilizing mixed bacteria evolution subculturing to improve 2-keto-L-gulonic acid yield

ActiveCN102352403AImprove utilization efficiencyImprove conversion efficiencyMicroorganism based processesFermentationBacillus megateriumTransformation efficiency

The invention discloses a method utilizing mixed bacteria evolution subculturing to improve the 2-keto-L-gulonic acid yield, which comprises the following steps of: (1) solid culture; (2) seed culturing: the bacillus megaterium and gluconobacter oxydans are inoculated into a new seed culture medium, are shake cultured in a shaker of 200-280r / min at 28-35 DEG C, 24h-48h is taken as the passage period, the volume ratio of 1%-10% is taken as the passage ratio to inoculate into the new seed culture medium and passages for 50-80 days; (3) purification; and (4) fermentation. The method utilizes themixed bacteria evolution subculturing to culture for tens of generations, the growth rate of the bacillus megaterium and gluconobacter oxydans and the efficiency of utilizing the gluconobacter oxydans to produce 2-keto-L-gulonic acid can be obviously improved, accordingly, the utilization rate of the culture medium can be improved, and the L-sorbose transformation efficiency is improved about 10%.

Owner:TIANJIN UNIV

2-keto-l-gulonic acid high concentration fermentation production technology

InactiveCN101392274AIncrease concentrationIncreased Gulonic Acid ConcentrationMicroorganism based processesFermentationHigh concentrationAlcohol

The invention discloses a production technique of 2-keto-L-gulonic acid by high concentration fermentation. In a fermentation medium adopted by the production technique, the initial sorbin concentration is 15mg / ml to 25mg / ml; fermentation is carried out for 4 hours to 8 hours; continuous sorbin feeding is started; fermentation is carried out for 36 hours to 44 hours and then sorbin feeding is finished; during the feeding process, the content of sorbin is controlled to be 15 mg / ml to 30 mg / ml; when fermentation is carried out for 24 hours to 40 hours, pH value is adjusted to be 7.1 to 7.3; when fermentation is carried out for 40 hours to 44 hours, pH value is adjusted to be 7.4 to 7.6 until fermentation is finished; and dissolved oxygen during the whole fermentation process is controlled to be 30 percent to 50 percent. The technique adopted by the invention has total fed sorbin with a concentration of 10.5 percent to 11.5 percent (W / V) at the end of fermentation; the concentration of gulonic acid of fermentation solution is raised by 10 percent to 15 percent; the conversion rates of alcohol and acid are respectively promoted by 3 percentage points; and stability is good; besides, the technique process has simple and convenient operation and is easy for wide application.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

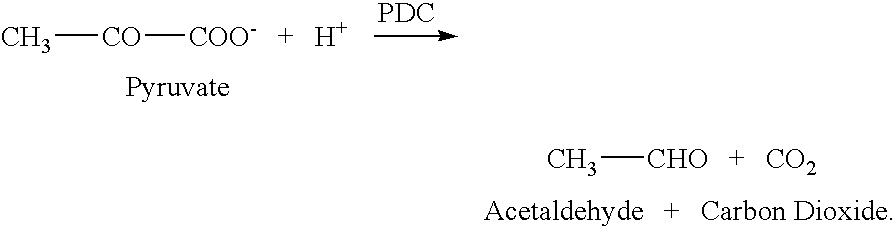

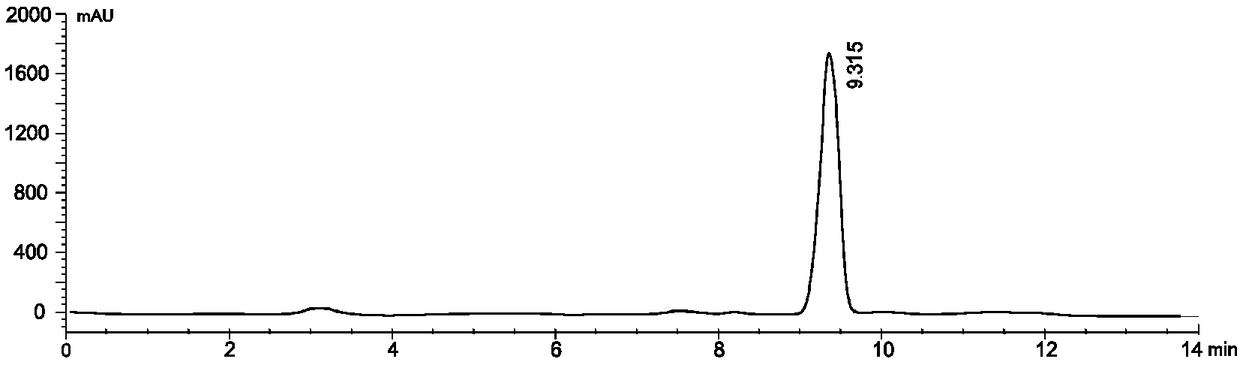

Enzymatic method for preparing L-xylose

The invention discloses an enzymatic method for preparing L-xylose and belongs to the field of bioengineering. In the method, 2-keto-L-gulonic acid is dissolved in a buffer containing magnesium ions and thiamine pyrophosphate, and pyruvate decarboxylase is added to the buffer for an enzyme-catalyzed reaction at a suitable temperature. After the end of the reaction, the production of the L-xylose is proved by a high performance liquid chromatograph. A new method for producing the L-xylose is found. The method is low in raw material cost, has no pollution to the environment, and has important economic and social benefits.

Owner:SHANGHAI LINKCHEM TECH CO LTD

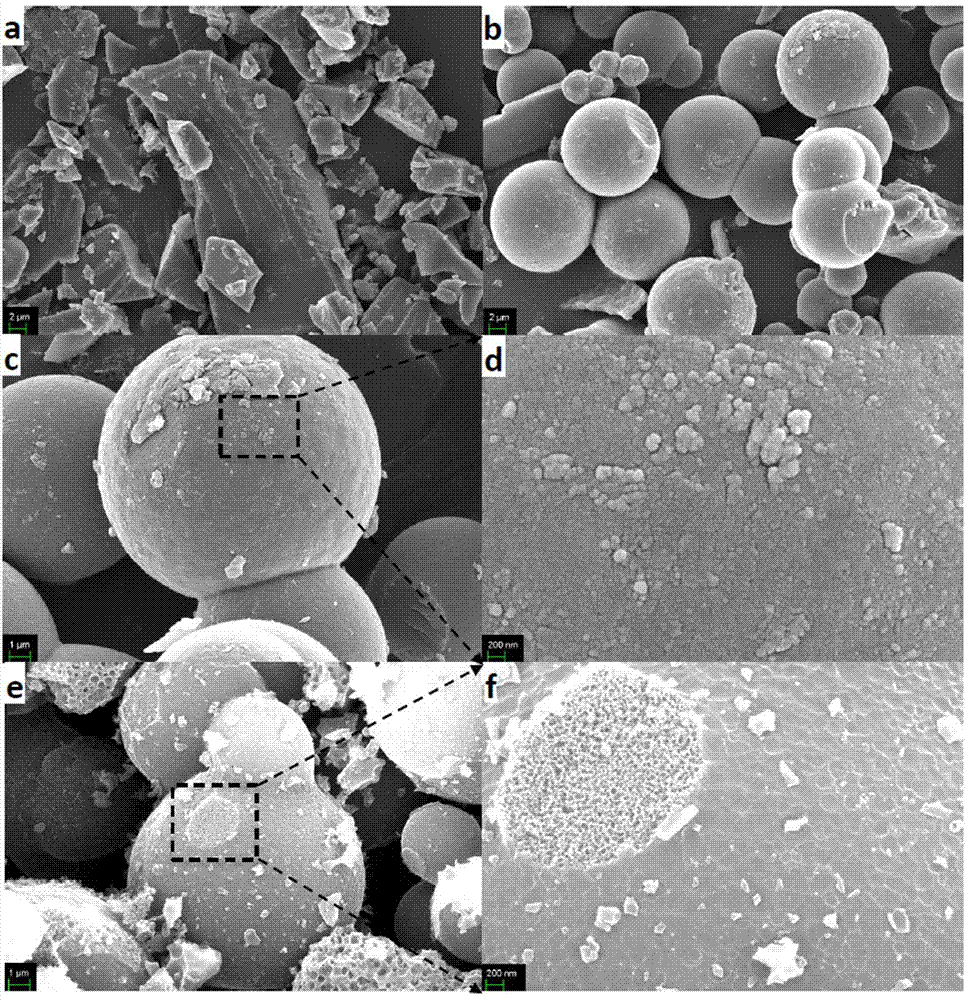

Method for preparing porous carbon spheres by using waste sugar solution and method for preparing electrode sheet by using carbon spheres

ActiveCN107010625ALarge specific surface areaImprove wettabilityCarbon compoundsHybrid capacitor electrodesSolution treatmentPorous carbon

The invention discloses a method for preparing porous carbon spheres by using a waste sugar solution. According to the method, the waste sugar solution, rich in 2-keto-L-gulonic acid, produced during production of vitamin C is used; the method comprises the following four steps: preforming hydrothermal carbonization, cleaning and drying the carbon spheres, preparing the porous carbon spheres and preparing an electrode. With the waste sugar solution as a precursor, through the hydrothermal carbonization, the carbon spheres rich in oxygen-containing functional groups on the surfaces are synthesized, and through KOH activation, the porous carbon spheres with relatively good electrochemical performance are prepared. By the method, high-added value utilization of the waste sugar solution produced during preparation of the vitamin C is achieved, the waste sugar solution treatment cost of a biopharmaceutical company is reduced, and the environment pollution is also reduced to a certain extent. The invention discloses a method for preparing an electrode sheet by using the carbon spheres.

Owner:CHINA UNIV OF MINING & TECH

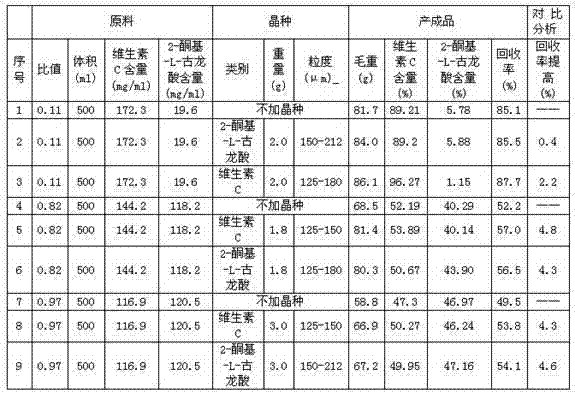

Method for extracting vitamin C and 2-keto-L-gulonic acid from vitamin C mother liquor

ActiveCN101555239AAvoid pollutionHighlight substantive featuresCarboxylic compound separation/purificationSocial benefitsSalting out

The invention provides a method for extracting a vitamin C and 2-keto-L-gulonic acid from a vitamin C mother liquor, comprising the following steps of: counteracting the vitamin C mother liquor, generating a vitamin C salt and a 2-keto-L-gulonic acid salt and obtaining a salt solution; mixing and cooling the salt solution so as to separate the 2-keto-L-gulonic acid salt out from the salt solution; dissolving the 2-keto-L-gulonic acid salt by water; removing cation by a cation exchange resin; obtaining the 2-keto-L-gulonic acid by concentrating, crystallizing and separating; taking the salt solution with the 2-keto-L-gulonic acid salt separated out and removing the cation ion by the cation exchange resin; and obtaining the vitamin C by concentrating, crystallizing and separating. The method has scientific process, simple operation, strong practicability, good separation effect and high recovery rate, increases economic benefits, avoids polluting the environment and has excellent economic benefits and social benefits.

Owner:ZHENGZHOU TUOYANG IND

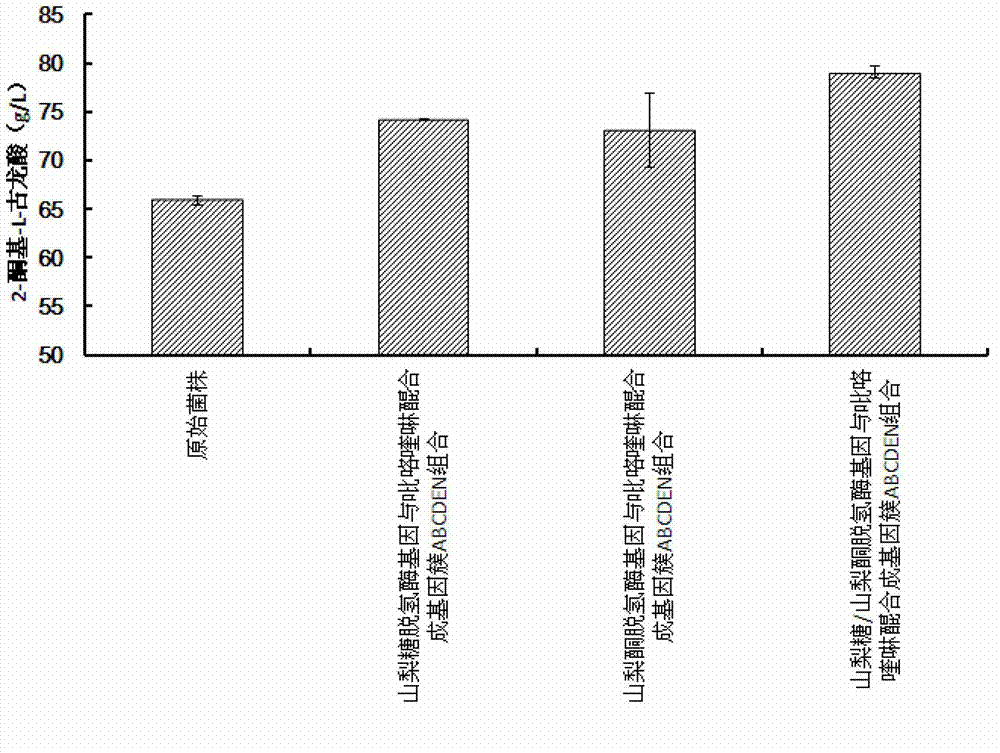

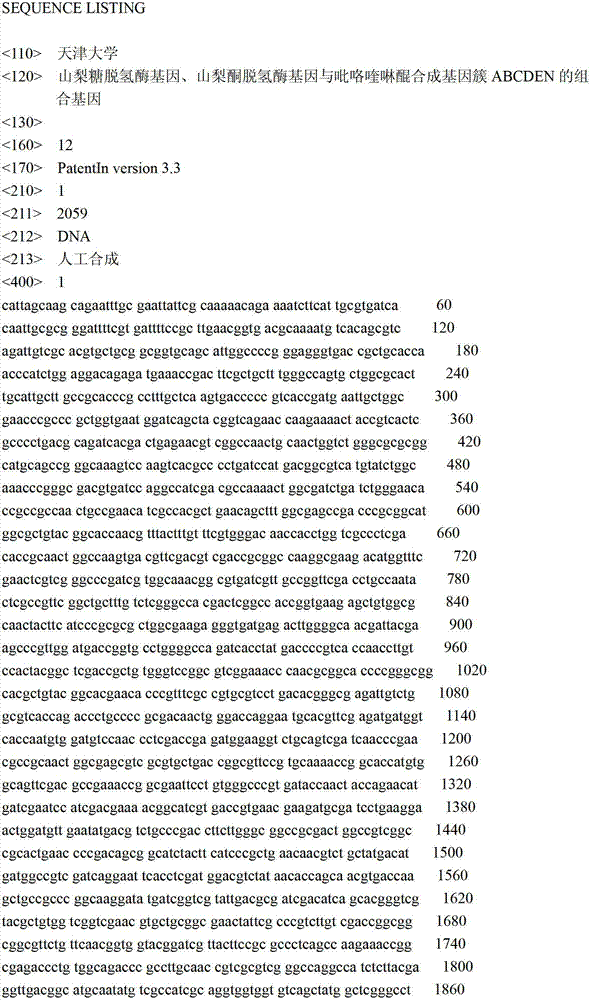

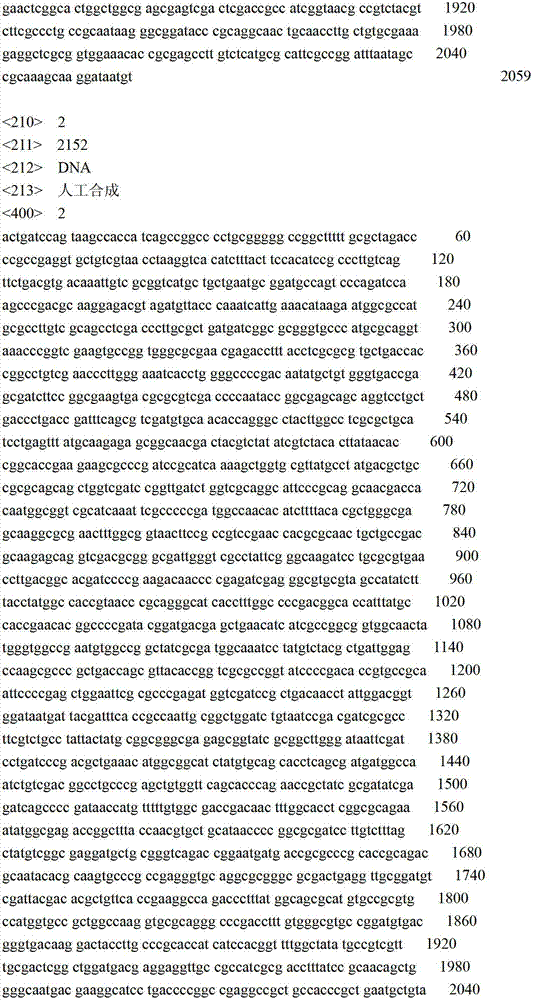

Combination gene of gene cluster ABCDEN by synthesizing sorbose dehydrogenase genes, sorbosone dehydrogenase genes and pyrroloquinoline quinone

The invention discloses a combination gene of a gene cluster ABCDEN by synthesizing sorbose dehydrogenase genes, sorbosone dehydrogenase genes and pyrroloquinoline quinone and relates to a SEQ ID No. 6 nucleotide sequence in a sequence table. According to the method, the yield of 2-keto-L-gulonic acids in mixed cultivation with bacillus megatherium can be improved apparently by constructing gluconobacter oxydans recombinant bacteria of different combination modes of the gene cluster ABCDEN synthesized by the sorbose dehydrogenase genes, the sorbosone dehydrogenase genes and the pyrroloquinoline quinine, and the yield can be improved as high as 20%.

Owner:TIANJIN UNIV

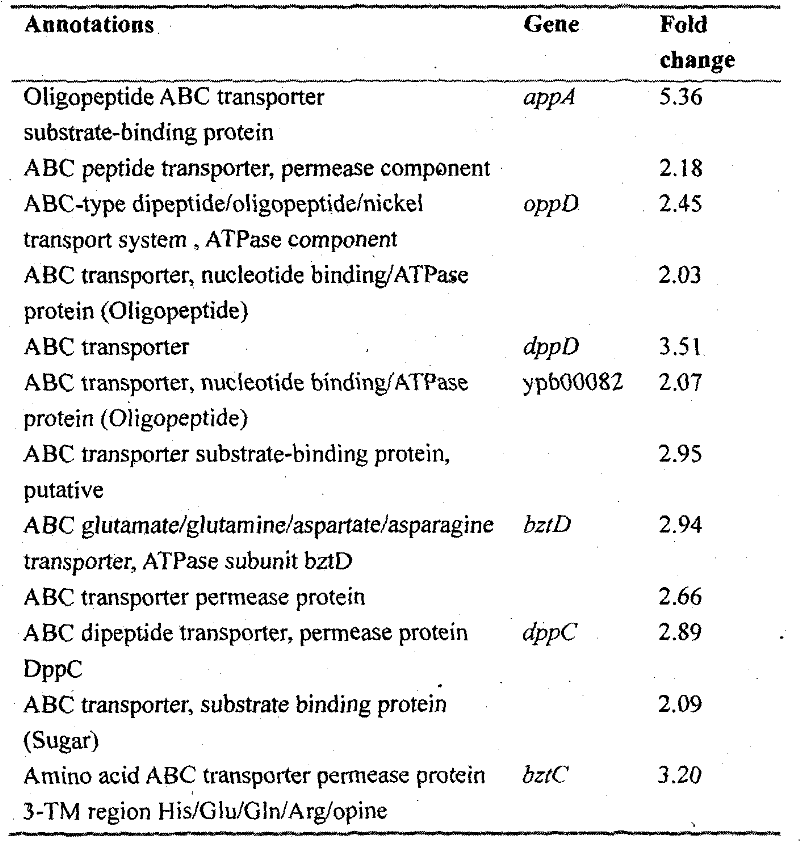

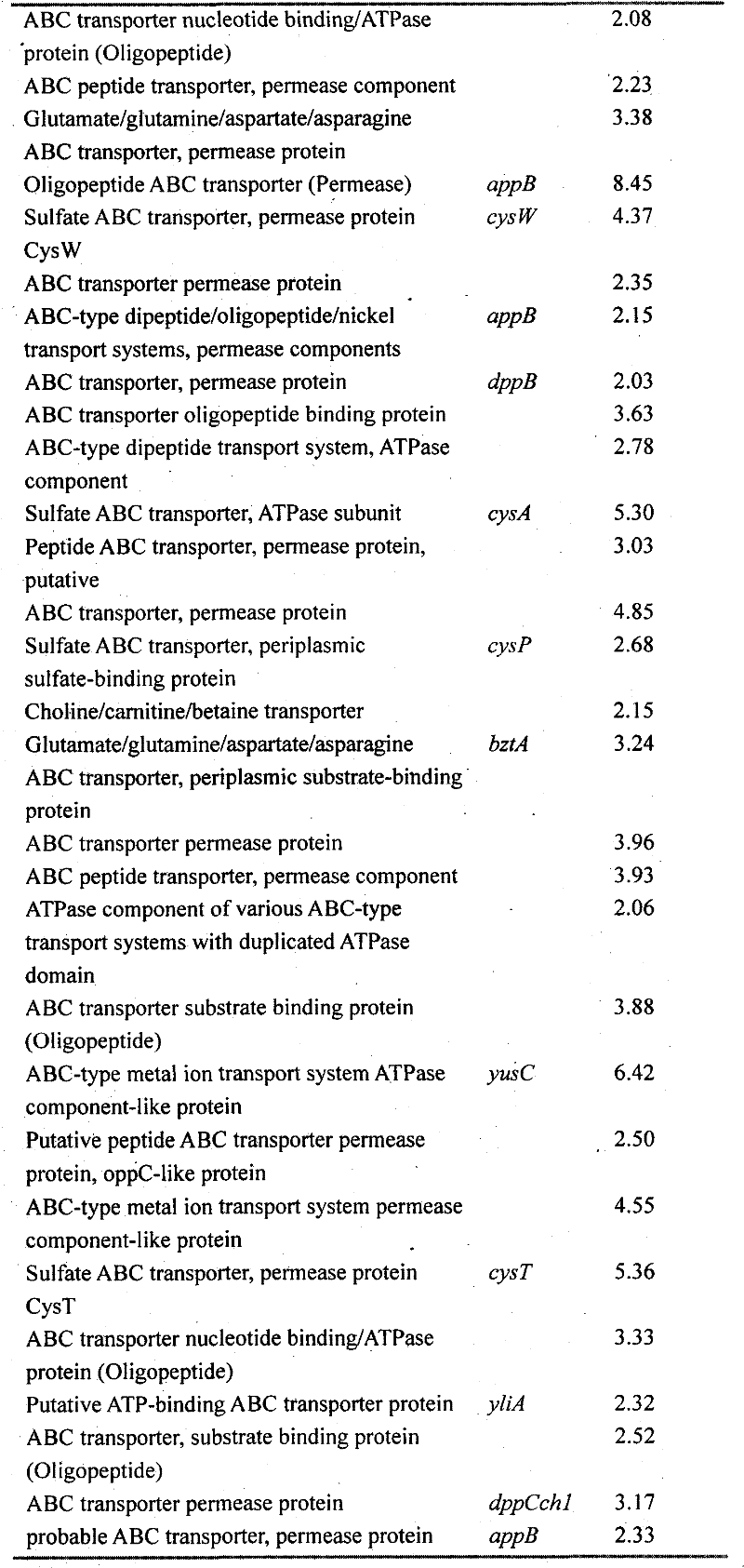

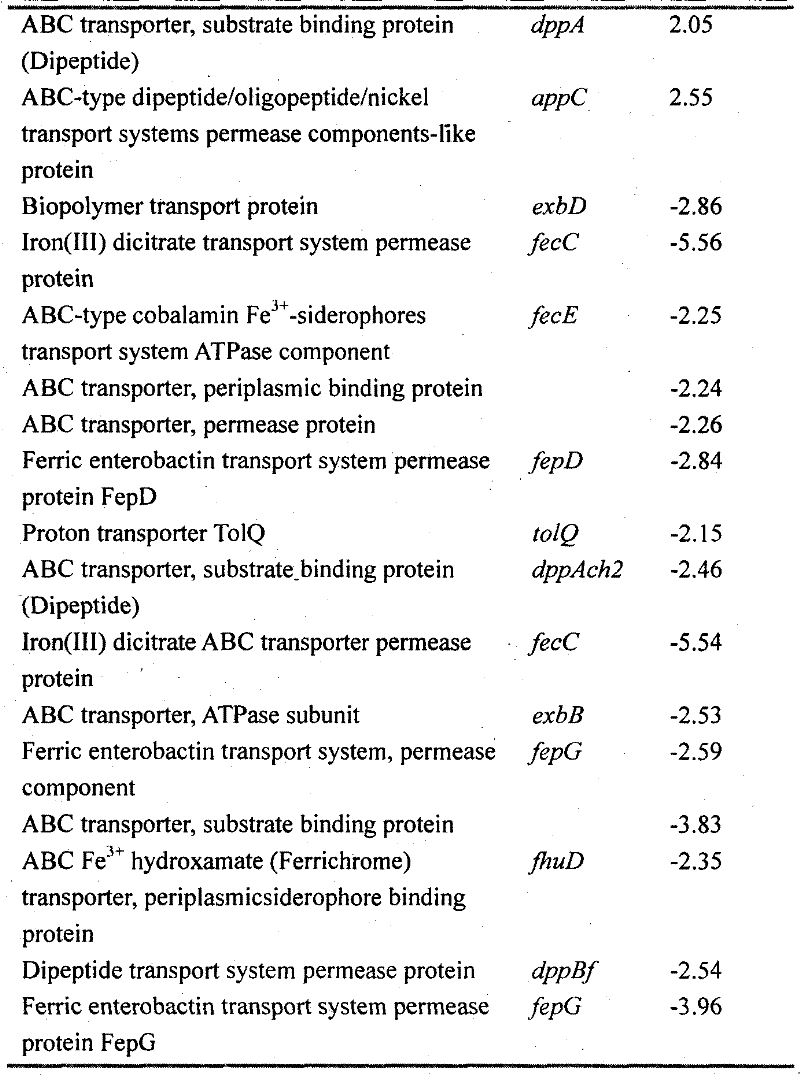

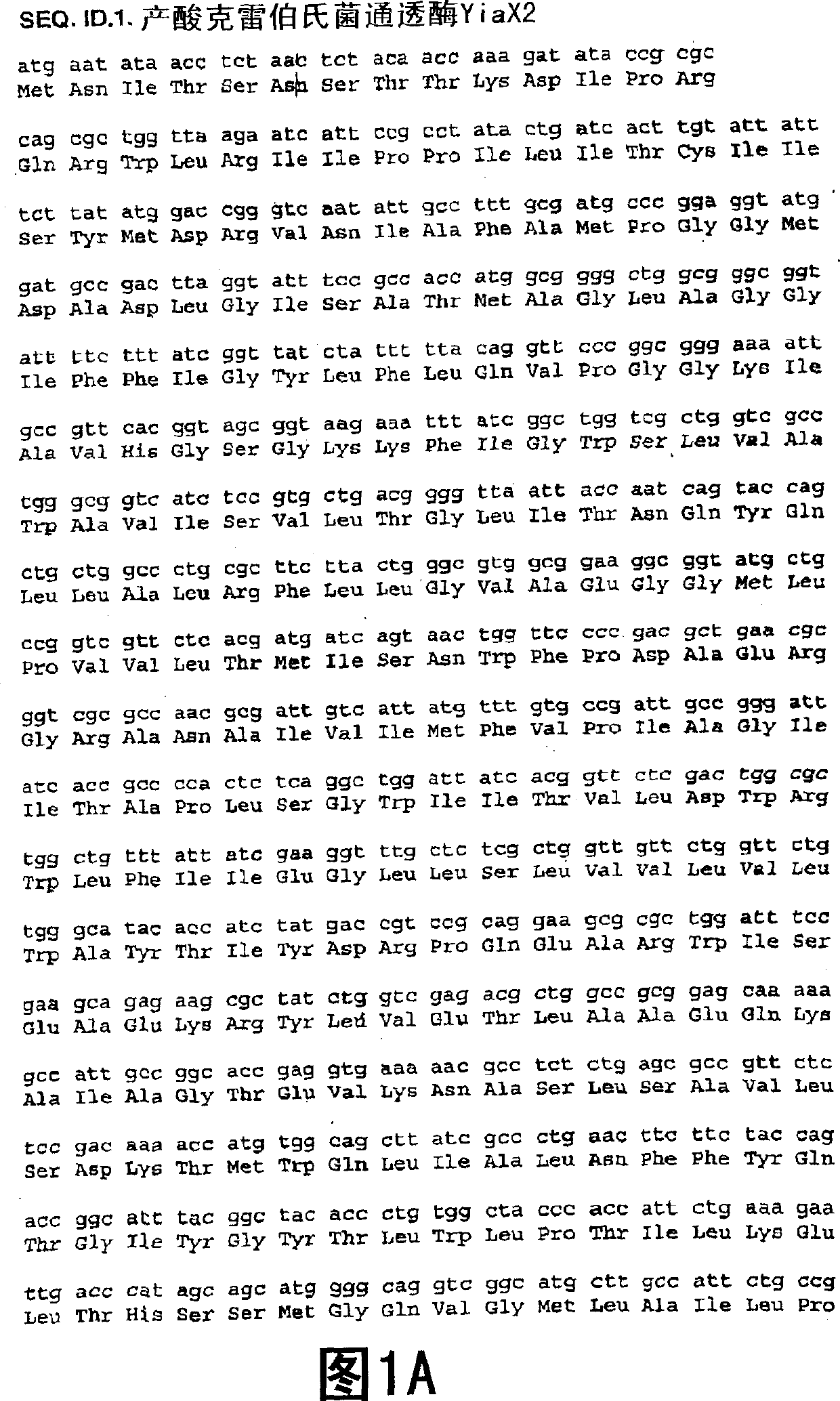

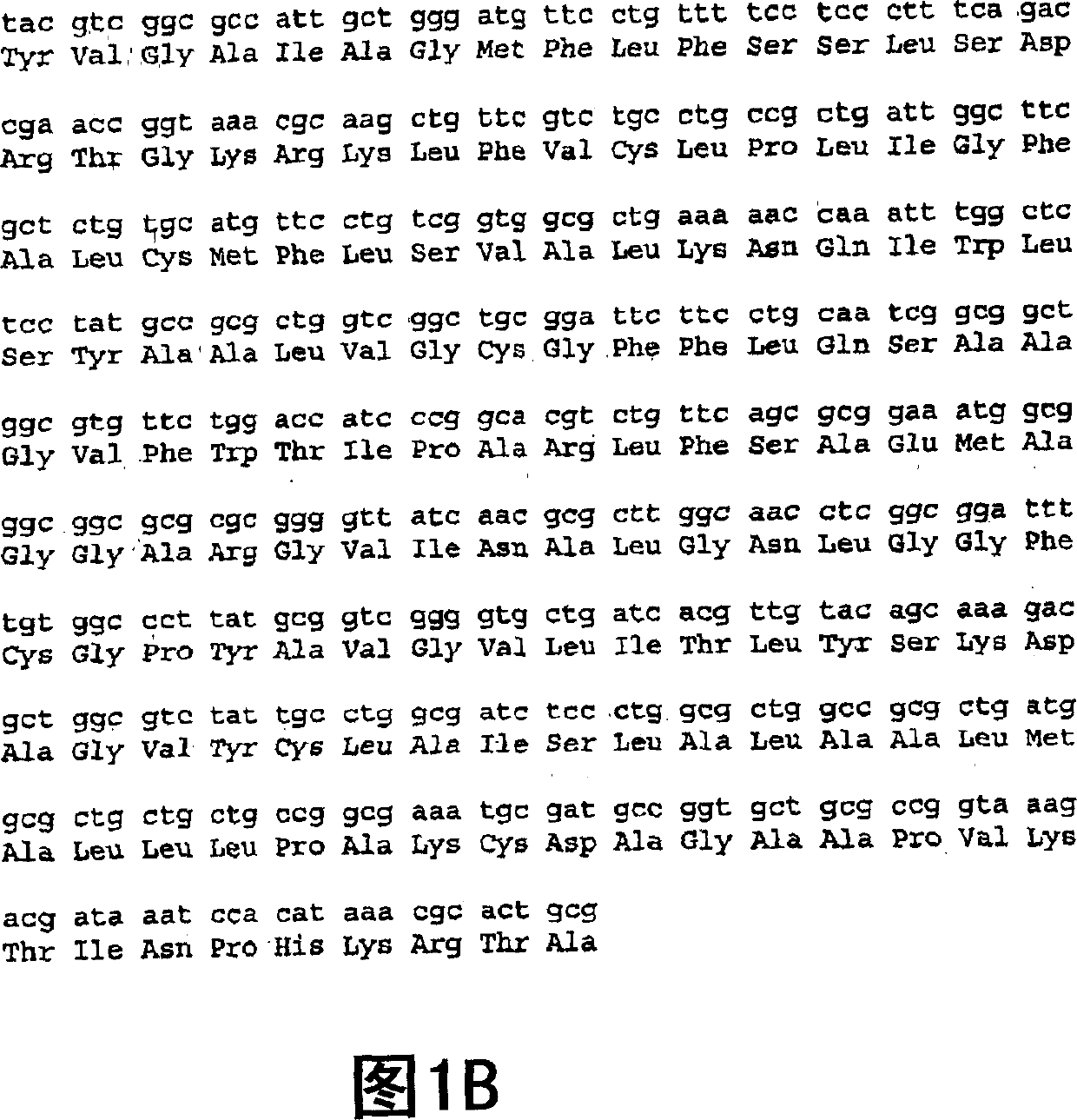

Gene capable of regulating and controlling inhibition of vitamin C fermented strain acid production during acid stress

InactiveCN102286614AReduce outputMicrobiological testing/measurementFermentationMembrane TransportersBasic research

The invention relates to a gene capable of regulating and controlling inhibition of vitamin C fermented strain acid production during acid stress and belongs to the technical fields of basic research on vitamin C prepared by fermentation and biological engineering. The key gene for regulating and controlling yield reduction of acid stress induced 2-Keto-L-Gulonic acid (2-KLG) in the production strains is determined, so a metabolic engineering strategy with high pertinence is generated. The expression condition of genes, in particular membrane transport protein genes, of acid-forming bacteria in the vitamin C mixed bacteria fermented system is analyzed by an expression profile chip technology. Compared with ketogenic gulonic acid bacteria subjected to single cultivation, the ketogenic gulonic acid bacteria subjected to mixed bacteria cultivation have 45 upregulated membrane transport protein genes and 15 down regulated membrane transport protein genes. The notable thing is that: 7 iron ion transport protein genes are inhibited to express. After acid stress, the iron ion transport protein genes are over expressed. During fermentation, the iron ions are added to inhibit mixed bacteria to ferment and generate acid. The result shows that the iron ion transport protein exerts reverse action in the process of yield reduction of 2-KLG generated by the acid stress induced mixed bacteria fermentation.

Owner:JIANGNAN UNIV

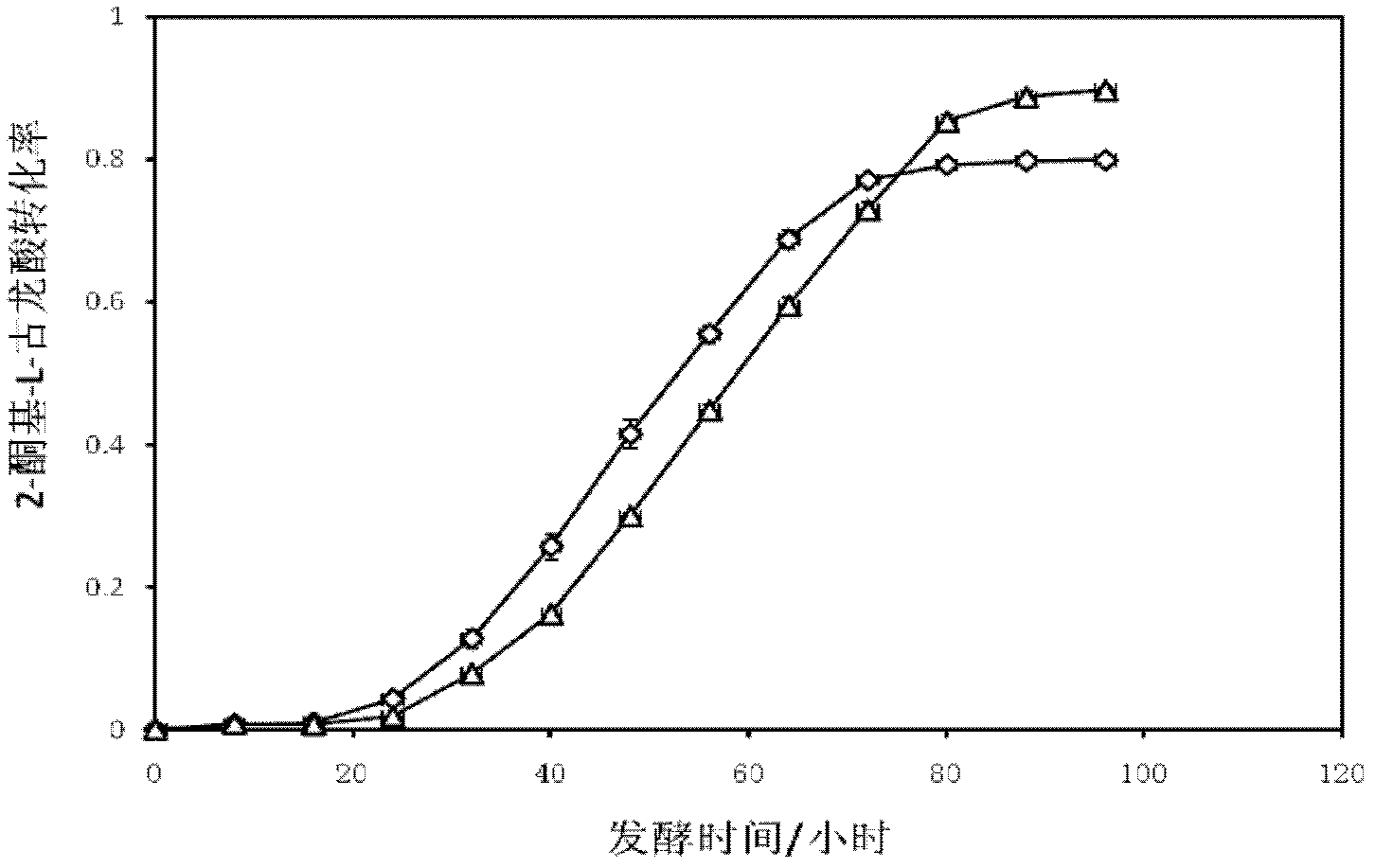

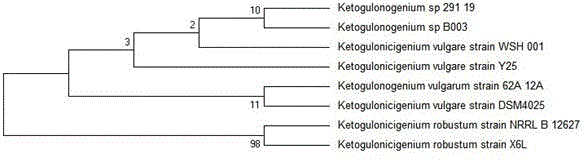

Strain for producing 2-keto-L-gulonic acid and production method thereof

InactiveCN104152365AStable traitsShorten the fermentation cycleBacteriaMicroorganism based processesMicroorganismMicrobiology

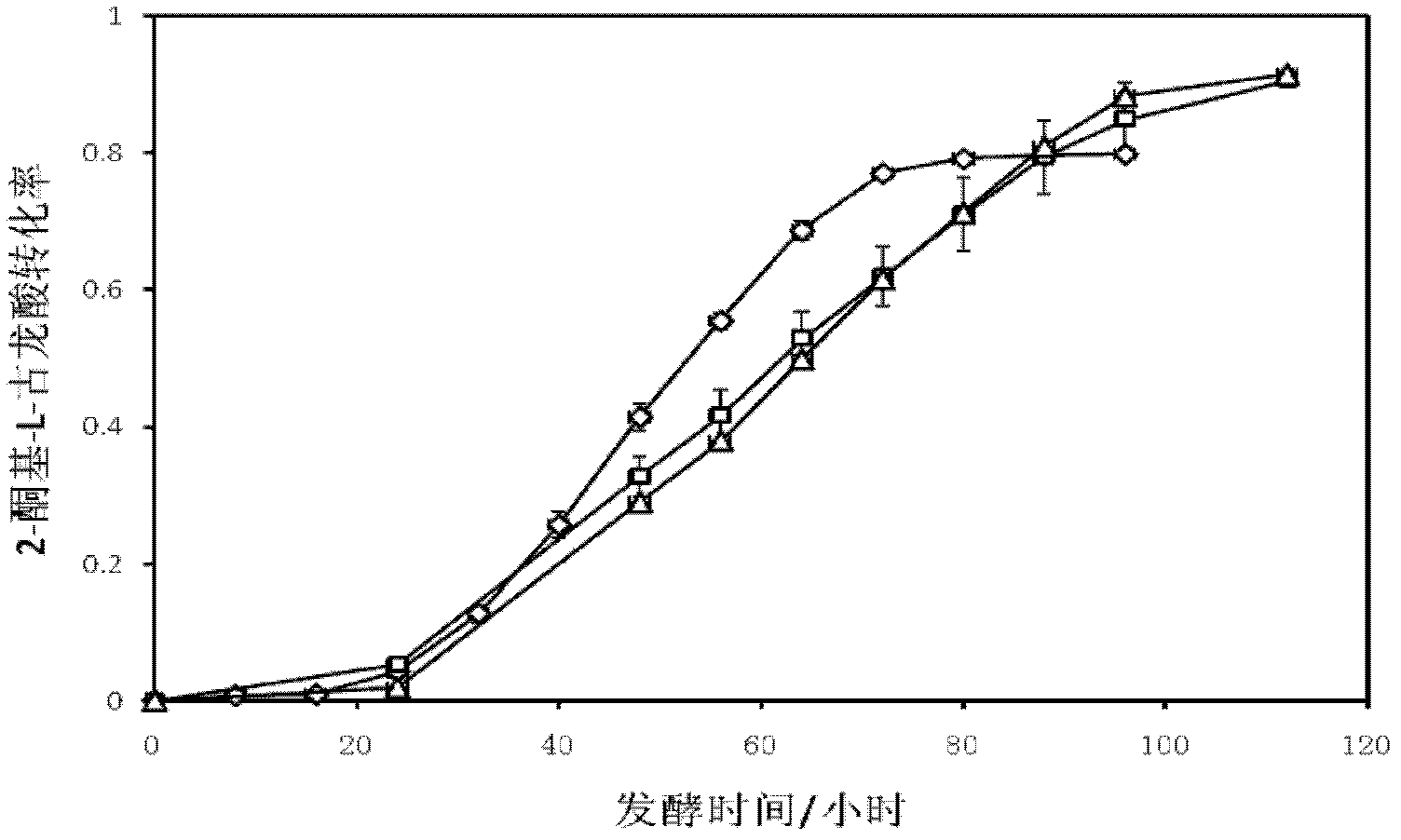

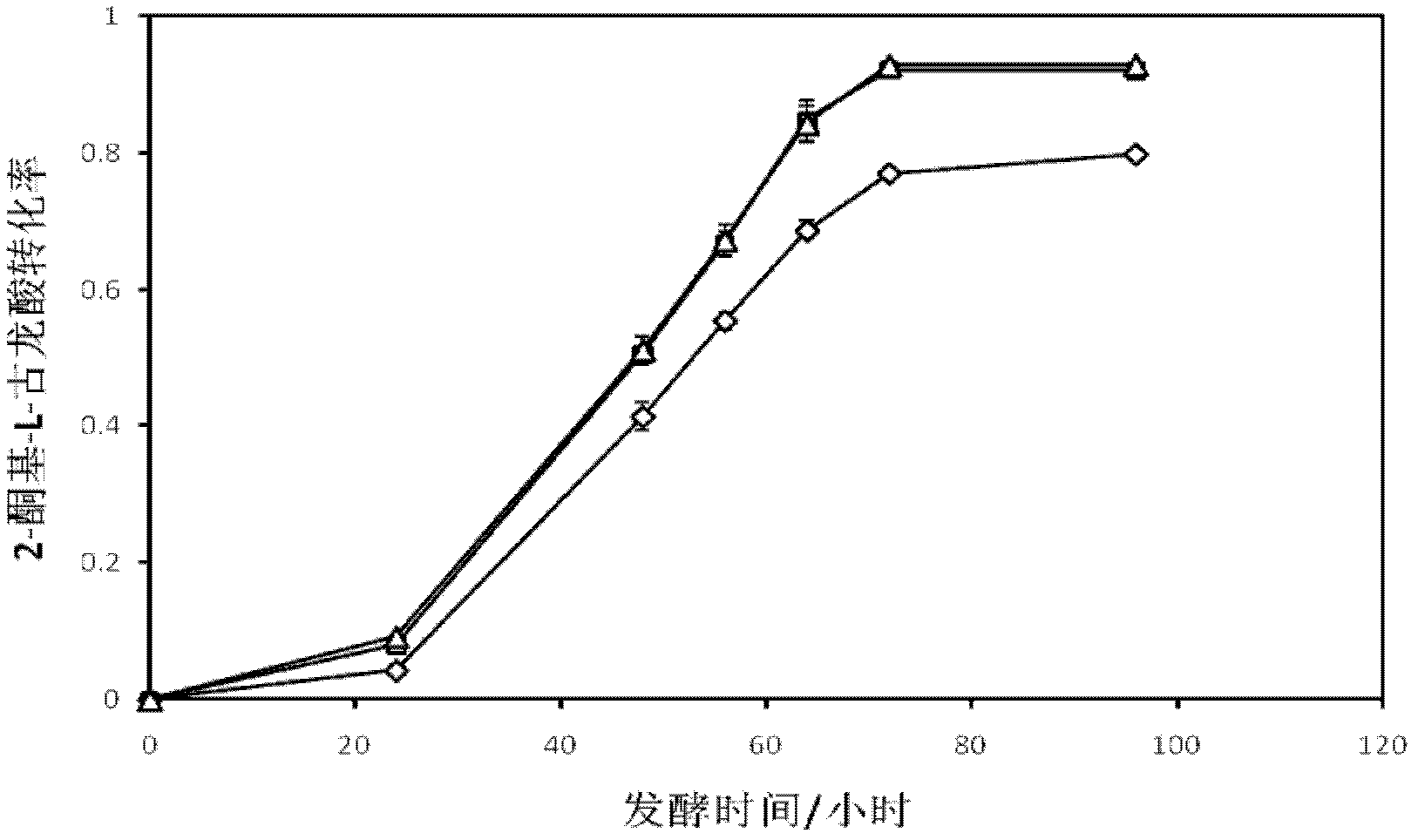

The invention belongs to the field of microbial fermentation, relates to a strain for producing 2-keto-L-gulonic acid and a production method of the strain, and in particular relates to a strain and process for converting a substrate namely L-sorbose into 2-keto-L-gulonic acid (2-KLG) by using a biological fermentation method. According to the strain disclosed by the invention, a new strain SPUB-003 which is stable in genetic character, can grow independently, and can be used for producing 2-KLG is obtained by separating and screening from soil and further performing artificial domestication. SPUB-003 is authenticated to be Ketogulonicigenium sp, and has been sent to General microorganism center of China Committee for Culture Collection of Microorganisms (CGMCC) for collection, wherein the collection date is July 3, 2013, and the collection number is CGMCC No.7876. SPUB-003 can perform independent growth and acid production at 20-34 DEG C; the strain can be used for independently producing 2-KLG by virtue of liquid state fermentation; after performing shake-flask fermentation for 24-96 hours, the conversion rate of obtained 2-KLG can be more than 70%; after fermenting for 24-68 hours by using a 5L fermentation tank, the conversion rate of 2-KLG can reach more than 80%. In a fermentation process, by adding micro physiological active substances, the conversion rate can be increased to more than 90%, and the fermentation period can be shortened.

Owner:SHENYANG PHARMA UNIVERSITY

Method for cleaner production of vitamin C

PendingCN108191799AEmission reductionReduce wasteOrganic chemistryAmmonium salt fertilisersHydrogenReaction temperature

The invention provides a method for cleaner production of vitamin C. The method comprises the following steps: adding 2-keto-L-gulonic acid, methanol and a catalyst into a reaction kettle and uniformly stirring; raising the temperature to 50 DEG C to 60 DEG C; after reflowing for 2 to 5h, obtaining a gulonate methyl ester solution; raising the temperature to 60 DEG C to 68 DEG C; then introducingammonia gas at a speed of 0.18 to 0.22mL / min until pressure in the reaction kettle is raised to 0.008 to 0.012MPa; then improving the speed of the introduced ammonia gas to 0.38 to 0.42mL / min until the pressure of the reaction kettle is 0.018 to 0.02MPa, so as to obtain a vitamin C ammonium salt methanol solution; cooling to 0 to 5 DEG C and filtering to obtain a vitamin C ammonium salt solid; after dissolving the solid with de-ionized water, treating through hydrogen type ion exchange resin to obtain the vitamin C and ammonium sulfate. The method provided by the invention has moderate reaction temperature; the yield of the vitamin C is improved and the reaction time of conversion is shortened; a byproduct ammonium sulfate fertilizer is produced and wastes are changed into valuable things;meanwhile, the production cost is reduced and economic and environment-friendly benefits are realized.

Owner:ZHENGZHOU TUOYANG IND

Method for concentrating, crystallizing and recovering vitamin C mother liquor

ActiveCN103923041AIncrease production costSugar derivativesSolution crystallizationEvaporationContinuous flow

The invention relates to a method for concentrating, crystallizing and recovering vitamin C mother liquor in a concentration and crystallization technology of the vitamin C mother liquor. The method comprises the following steps: performing decompression, evaporation and concentration on the vitamin C mother liquor in an evaporator, wherein the concentration condition is characterized in that the relative vacuum degree is greater than or equal to 0.092MPa, when the content ratio of 2-keto-L-gulonic acid to vitamin C in the vitamin C mother liquor is less than or equal to 1.13, concentrating the vitamin C mother liquor to vitamin C under a quasi stabilization zone under the concentration condition, concentrating the vitamin C mother liquor to 2-keto-L-gulonic acid under a quasi stabilization zone under the concentration condition; when the content ratio of 2-keto-L-gulonic acid to vitamin C in the vitamin C mother liquor is less than or equal to 1.13, adding the vitamin C mother liquor in continuous flow, concentrating to a terminal point, filtering, and recovering to obtain the vitamin C crystals. The method solves the problems that the esterification conversion reaction of the 2-keto-L-gulonic acid on industrial production of vitamin C is stable, when the content of 2-keto-L-gulonic acid in the vitamin C mother liquor is high, recovery rate through concentration and crystallization of the vitamin C mother liquor is low, and the crystallization recovery rate of the vitamin C mother liquor is influenced, and the production cost is increased.

Owner:NORTHEAST PHARMA GRP

Preparation method of 2-keto-L-gulonic acid

InactiveCN102242178AReduce inhibitionIncreased concentration of acid productionMicroorganism based processesFermentationCalcium hydroxideSaccharic acid

The invention relates to a preparation method of 2-keto-L-gulonic acid. In the invention, since a pH value in the fermentation process is controlled by utilizing calcium hydroxide instead of sodium carbonate, inhibition of acid production by a high-concentration product can be avoided, fermentation reaction progress is facilitated, the content of the gulonic acid at the fermentation destination reaches 105-110 mg / ml, the saccharic acid conversion rate is 94-96%, the concentration of produced gulonic acid is improved, the technical difficulty can be reduced, the operation is simple, the after extraction is easy, and the equipment utilization rate is improved.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

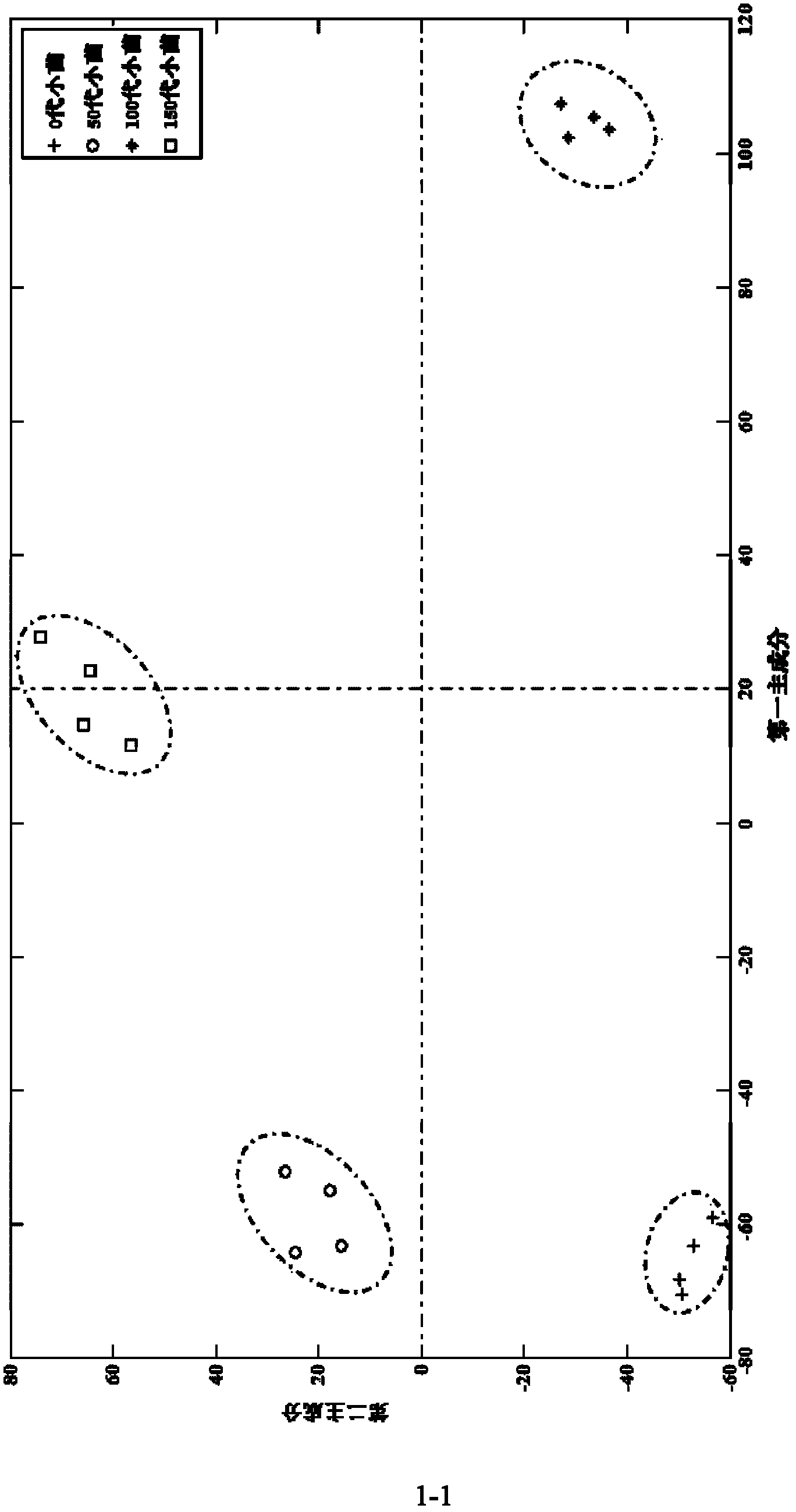

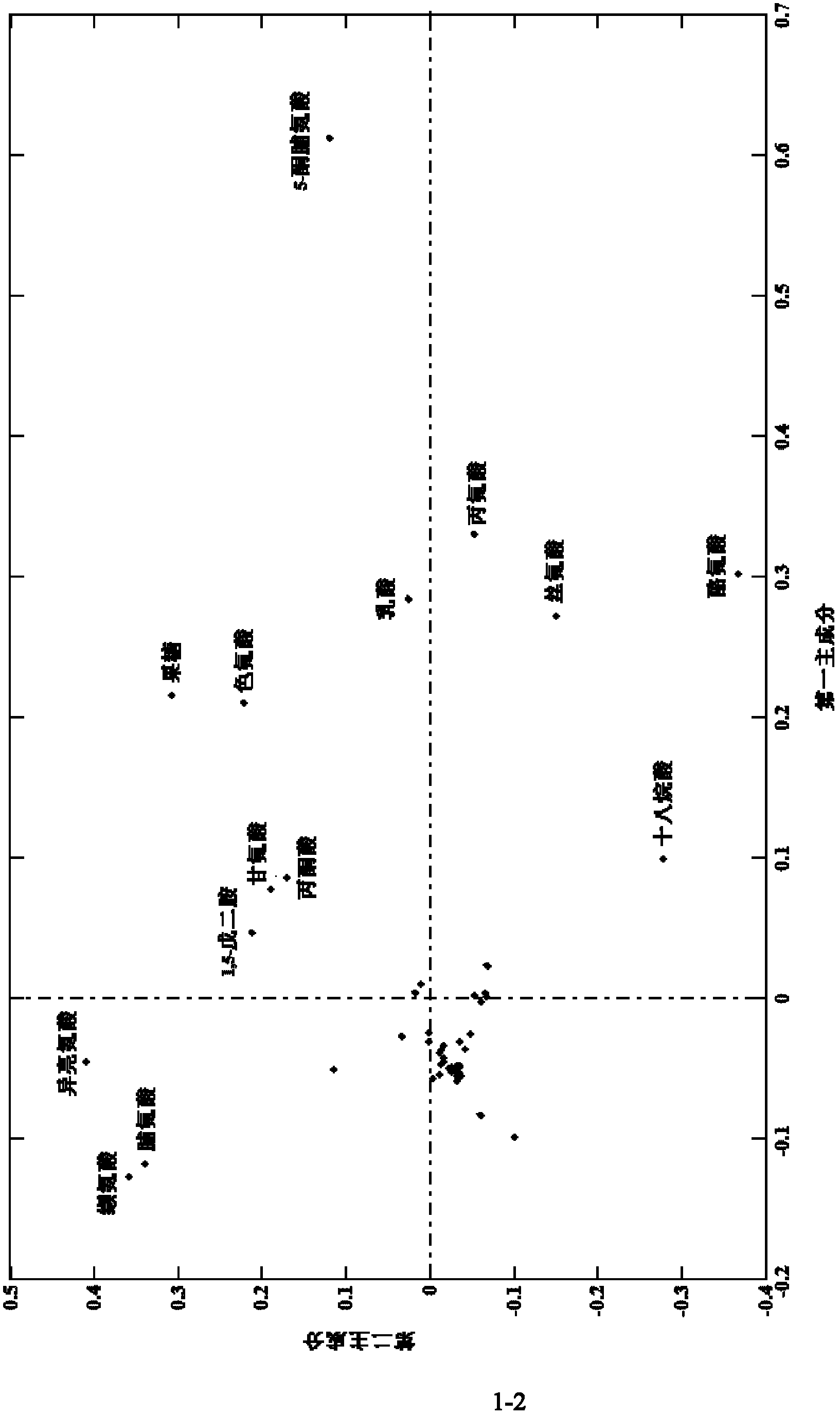

Method for detecting nutrition environment change in subculture process of vitamin C production strain

InactiveCN102634562AIncrease productionPromote fermentationComponent separationMicrobiological testing/measurementBacillus megateriumNutrition

The invention discloses a method for detecting nutrition environment change in a subculture process of a vitamin C production strain. The method comprises the following steps of: subculture of mixed strains, detection on matters in a nutrition environment, analysis on main ingredients and analysis on the process. The method can be used for finding important matters influencing the subculture nutrient environment from revelation of the influence of the mixed strain subculture on bacillus megaterium, gluconobacter oxydans and mixed strain systems, and the change rules of the contents of the matters provide fundamental basis for understanding the mechanism of action of the subculture to promote the growth of gluconobacter oxydans and the production of 2-keto-L-gulonic acid hydrate, thus providing fundamental basis for further optimizing the fermentation process and improving the yield of vitamin C.

Owner:TIANJIN UNIV

2-keto-L-gulonic acid fermentation process

InactiveCN102586380AReduce dosageReduce manufacturing costMicroorganism based processesFermentationMonopotassium phosphateNutrients substances

The invention relates to a 2-keto-L-gulonic acid fermentation process. Culture medium containing sorbose, corn steep liquor, urea, magnesium sulfate, monopotassium phosphate and light calcium carbonate nutrient substances is added into a fermentation container, mixed bacteria liquid which can convert the sorbose into 2-keto-L-gulonic acid is added, fermentation is carried out for 2 to 12 hours, lysozyme is added, the dosage of the lysozyme in the fermentation broth is 10U / ml to 10000U / ml, culture is continued, the culture temperature is controlled at 28 DEG C to 35 DEG C in the whole fermentation process, the culture pH value is controlled at 5.4 to 8.5, and fermentation is finished until the residual sorbose in the fermentation broth is lower than 1mg / ml. Through the process, the dosage of the lysozyme is reduced, the fermentation period is shortened by 10 to 15 hours, the production efficiency is increased, and the production cost is reduced.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

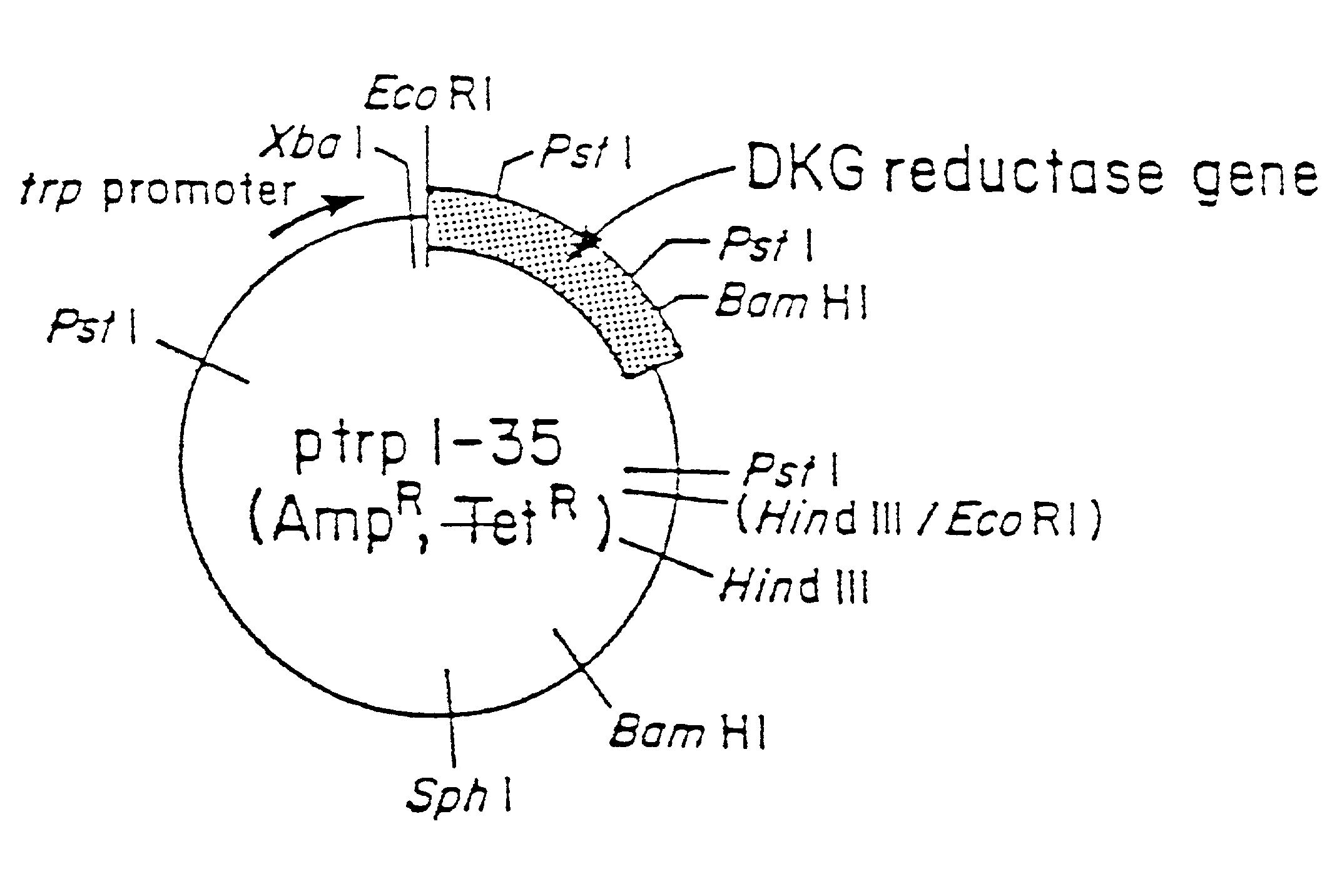

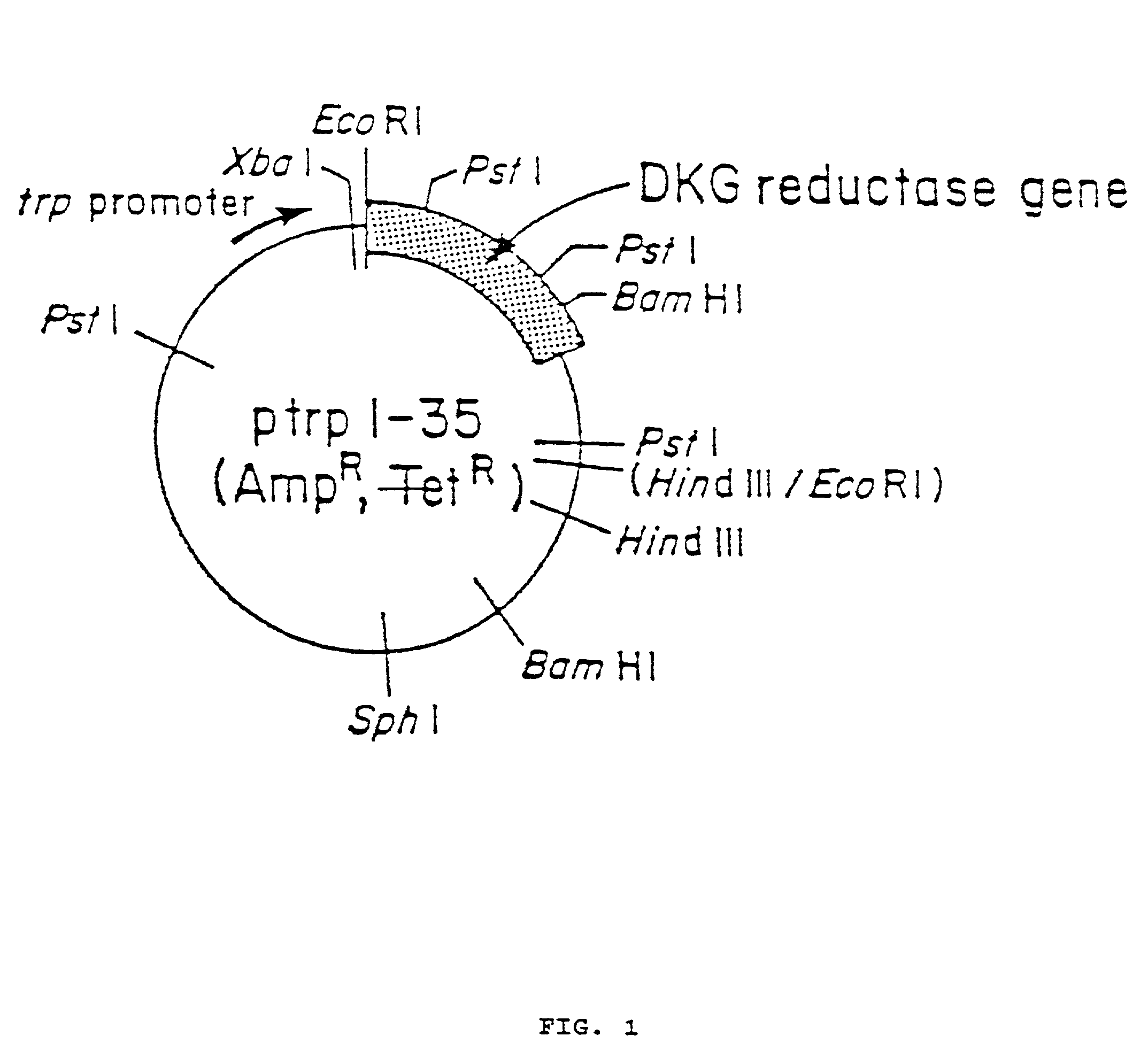

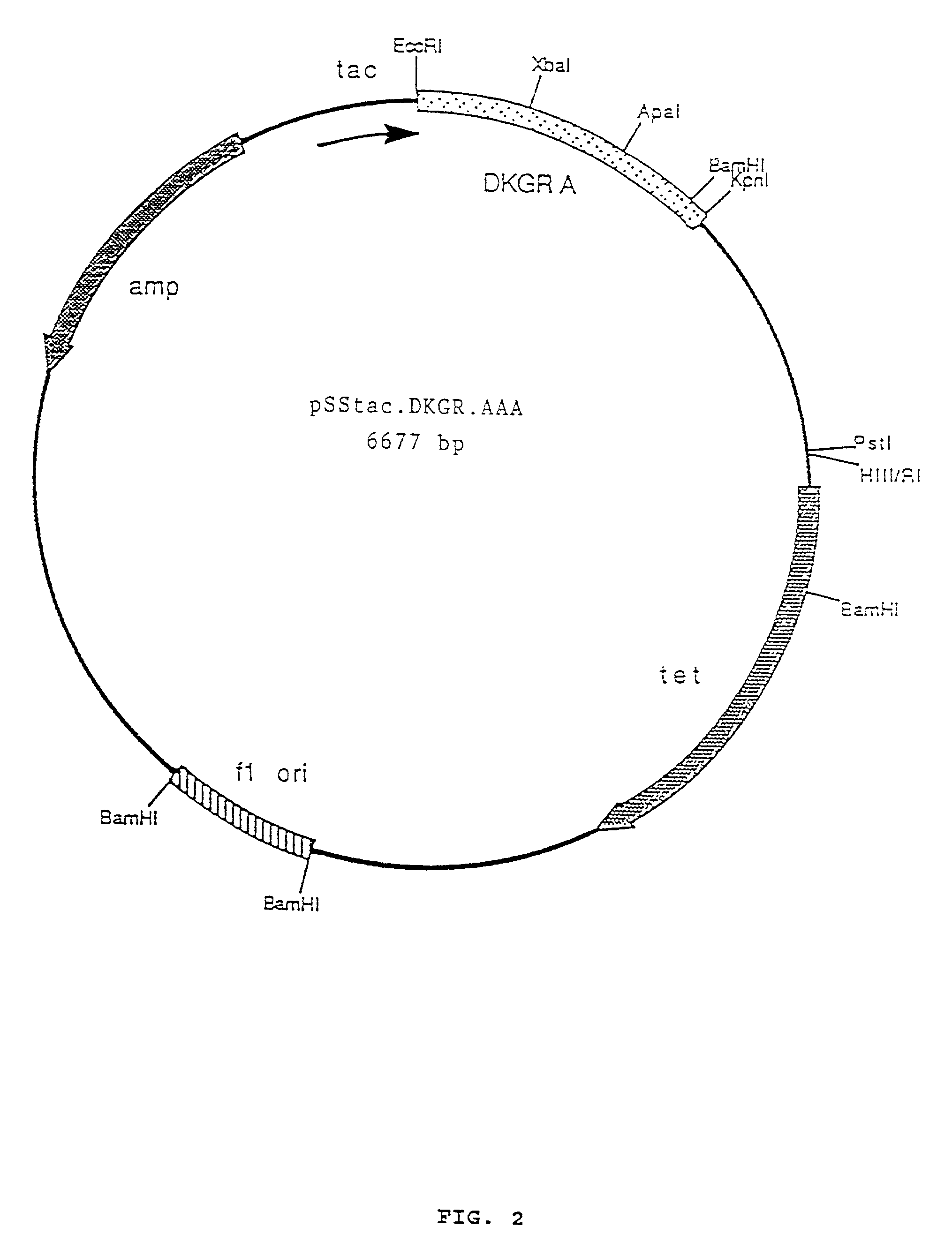

Enzymes for the production of 2-keto-L-gulonic acid

InactiveUS7256027B1High expressionImprove stabilitySugar derivativesBacteriaGluconic acidSite-directed mutagenesis

Mutants of 2,5-diketo-D-gluconic acid reductase A, an enzyme used to produce 2-keto-L-gulonic acid, a precursor of ascorbic acid (vitamin C) are prepared by site-directed mutagenesis. These mutants have increased catalytic activity, increased expression levels, and / or enhanced temperature stability.

Owner:RUTGERS THE STATE UNIV

Process for preparing metal ascorbate and its precursor

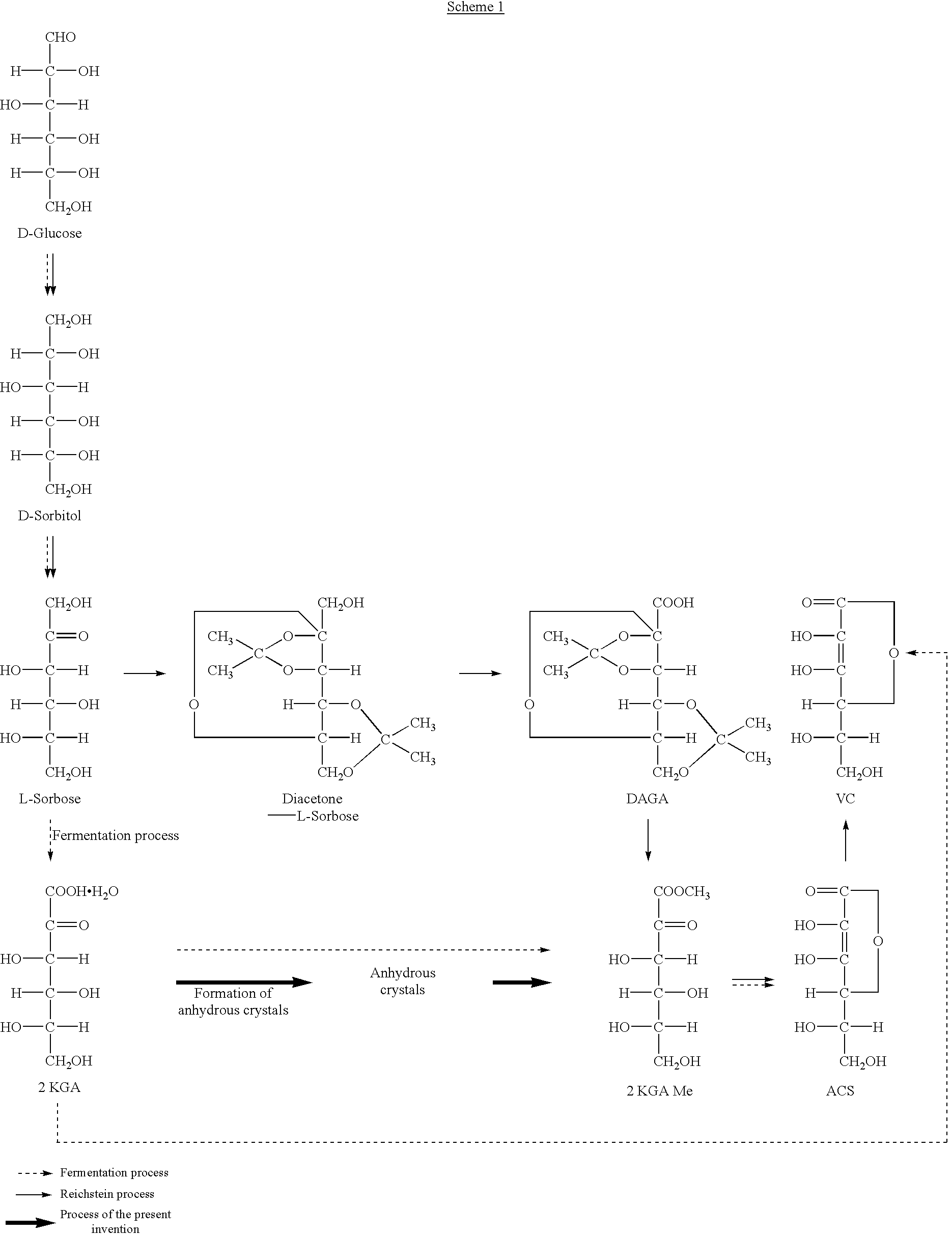

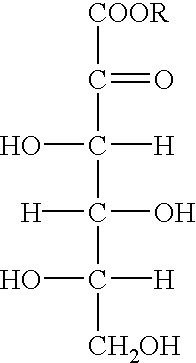

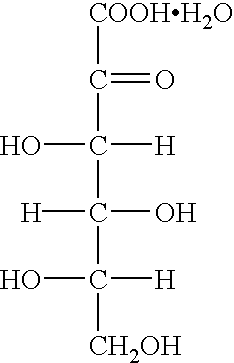

A novel esterification process of 2-keto-L-gulonic acid is provided to obtain an improve degree of esterification. According to the process, 2-keto-L-gulonic acid anhydrous crystals are formed from its monohydrate crystals in water-soluble alcohol solvent. The anhydrous 2-keto-L-gulonic acid is esterified with lower alcohol to obtain a lower alkyl ester of 2-keto-L-gulonic acid. The resultant ester is lactonized to obtain a metal L-ascorbate.

Owner:BASF AG

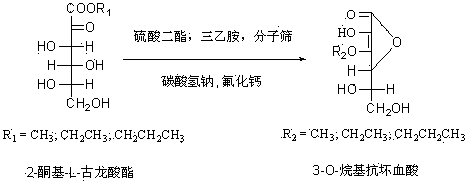

Preparation method for 3-O-alkyl ascorbic acid

InactiveCN103467420ASimple post-processingNovel synthetic routeOrganic chemistrySodium bicarbonateMolecular sieve

The invention discloses a preparation method for 3-O-alkyl ascorbic acid. The preparation method comprises the steps that under protection of nitrogen, 2-keto-L-gulonic acid ester reacts with sulfuric acid diester at the presence of catalyst molecular sieves, and an obtained intermediate under the action of sodium bicarbonate and calcium fluoride generates the 3-O-alkyl ascorbic acid. According to the preparation method, a synthetic route is simple, a synthetic method is novel, a process is easy and convenient to achieve, postprocessing is simple, the yield and purity of products are high, catalysts are low in price and easy to obtain, the environment is not affected, and the preparation method is suitable for industrial production.

Owner:CHONGQING TECH & BUSINESS UNIV

Single-strain preparation and fermentation technology based on fermentation of 2-keto-L-gulonic acid

InactiveCN103114107AEasy to manageTo promote metabolismMicroorganism based processesFermentationLiquid mediumNormal growth

The invention provides a single-strain preparation and fermentation technology based on the fermentation of 2-keto-L-gulonic acid. According to the technology, in the strain preparation and fermentation process, the bacillus megatherium and the ketogulonicigenium vulgaer are separately cultured, the bacillus megatherium is cultured in a liquid medium until reaching the end point so as to obtain the cell lysis solution for standby use; and the independently stored ketogulonicigenium vulgaer is sequentially activated and cultured, and isolated and screened, and is continuously inoculated to an inclined surface to enlarge in cultivation together with seed solution, and then is transferred into a fermentation medium to ferment. The bacillus megatherium is respectively added to the culture at each level, of the ketogulonicigenium vulgaer based on the 3 to 30% of the inoculum size, so that the normal growth and metabolism of the ketogulonicigenium vulgaer is promoted. By adopting the technology, the negative effect of a large strain to a small strain during mixing the large strain with the small strain to culture and ferment in the conventional technology can be avoided, the benefits are provided for genetic improvement, screening, culturing and storage of the small strain and management in the strain growth and metabolism process, and the fermentation period is reduced.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

Method for extracting vitamin C and 2-keto-L-gulonic acid from vitamin C mother liquor

ActiveCN101555239BAvoid pollutionHighlight substantive featuresCarboxylic compound separation/purificationSocial benefitsSalting out

The invention provides a method for extracting a vitamin C and 2-keto-L-gulonic acid from a vitamin C mother liquor, comprising the following steps of: counteracting the vitamin C mother liquor, generating a vitamin C salt and a 2-keto-L-gulonic acid salt and obtaining a salt solution; mixing and cooling the salt solution so as to separate the 2-keto-L-gulonic acid salt out from the salt solution;dissolving the 2-keto-L-gulonic acid salt by water; removing cation by a cation exchange resin; obtaining the 2-keto-L-gulonic acid by concentrating, crystallizing and separating; taking the salt solution with the 2-keto-L-gulonic acid salt separated out and removing the cation ion by the cation exchange resin; and obtaining the vitamin C by concentrating, crystallizing and separating. The methodhas scientific process, simple operation, strong practicability, good separation effect and high recovery rate, increases economic benefits, avoids polluting the environment and has excellent economic benefits and social benefits.

Owner:新拓洋生物工程有限公司

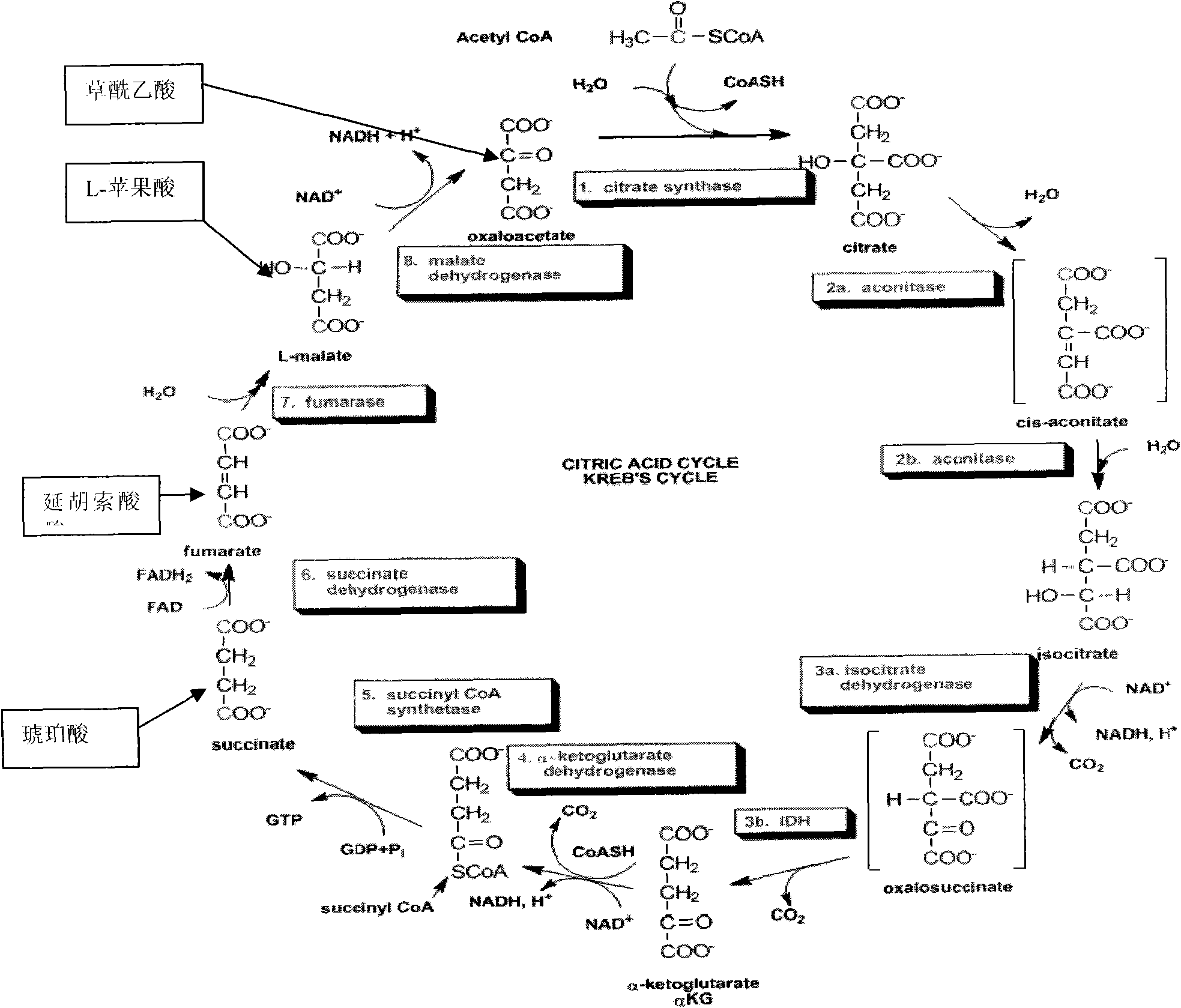

Application of tetra-carbonic acid or salt thereof to preparing 2-keto-L-gulonic acid in tricarboxylic acid cycle

InactiveCN101851645AIncrease productionShort cycleMicroorganism based processesFermentationTricarboxylic acidKetone

The invention relates to an application of tetra-carbonic acid or salts thereof, in particular to application of tetra-carbonic acid or salts thereof in preparation of 2-keto-L-gulonic acid in fermentation engineering and biological technical fields. Meanwhile, the invention further provides a culture medium for preparing 2-keto-L-gulonic acid and a method for preparing 2-keto-L-gulonic acid fromthe tetra-carbonic acid or the salts thereof in the tricarboxylic acid cycle.

Owner:仪宏

Method for improving activity of 2-keto-L-gulonic acid fermentation strains

The invention discloses a method for improving the activity of 2-keto-L-gulonic acid fermentation strains, and belongs to the technical field of microbial fermentation. The method includes separately disinfecting nitrogen sources and carbon sources in culture media in 2-keto-L-gulonic acid seed tanks; cooling the nitrogen sources and the carbon sources until the temperatures of the nitrogen sources and the carbon sources range from 28 DEG C to 30 DEG C and mixing the nitrogen sources and the carbon sources with one another. The method has the advantages that harmful substances can be reduced by the aid of a process for separately disinfecting nitrogen and carbon, accordingly, nutritious components of the culture media are rarely destructed, the method is favorable for production and reproduction of the production strains, the activity of the strains can be improved, and the 2-keto-L-gulonic acid fermentation periods can be shortened.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

Method for increasing output of 2-keto-L-gulonic acid by strengthening mutual effect of two bacteria

InactiveCN103045710AImprove utilization efficiencyImprove conversion efficiencyMicroorganism based processesFermentationMicrobiologyGluconobacter oxydans

Owner:TIANJIN UNIV

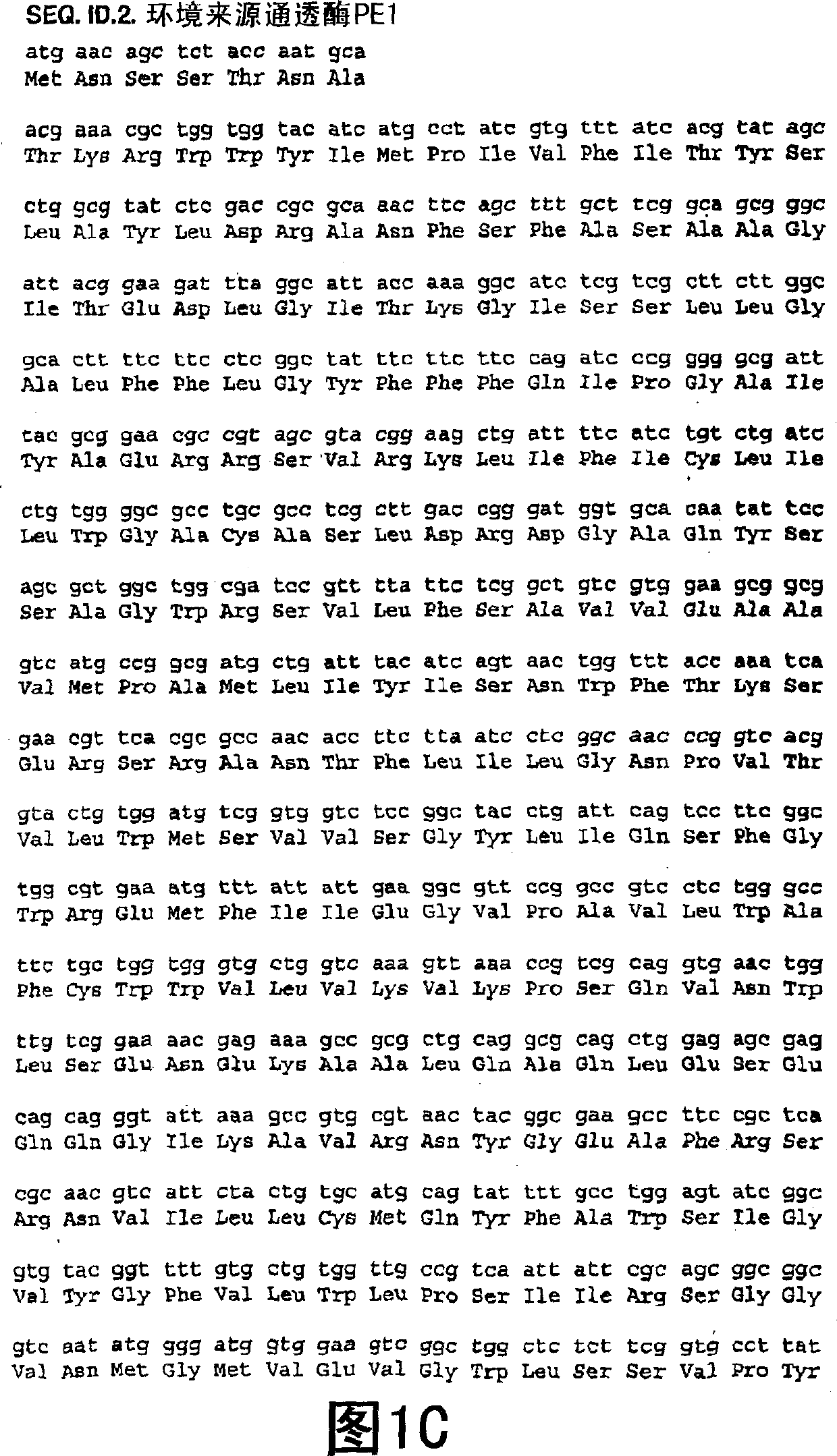

Enhanced 2-keto-L-gulonic acid production

A method for enhancing a host cell's biosynthetic production of 2-KLG is described. Such method comprises selecting a host cell that has an at least partially intracellular synthetic pathway which utilizes 2,5-DKG to produce 2-KLG; increasing the transport of said 2,5-DKG into said host cell while maintaining the integrity of the host cell; culturing the host cell to produce said 2,5-DKG; and producing 2-KLG. The transport of the 2,5-DKG is increased by transforming into the host cell DNA encoding for one or more enzymes transporting the 2,5-DKG into the host cell.

Owner:GENENCOR INT INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com