Strain for producing 2-keto-L-gulonic acid and production method thereof

A technology of keto-gulonic acid bacteria and gulonic acid, which is applied in the field of bacterial strains in which the substrate L-sorbose is transformed into 2-keto-L-gulonic acid, can solve the problems of large pollution, high material consumption, complex process control, etc., and achieve The effect of shortening the fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Implementation example 1: biological characteristics of ketoglobulina SPUB-003

[0035] After Gram staining, ketoglobulina SPUB-003 was a Gram-negative brevibacterium, which could form short chains or filaments, but could not form spores. The bacterium was grown on the slant medium for 4 days, and its colony form was point-like, raised, complete, smooth round colony, and the surface of the colony was oily, transparent, and almost no pigment was produced. Its physiological and biochemical indicators are shown in Table 1.

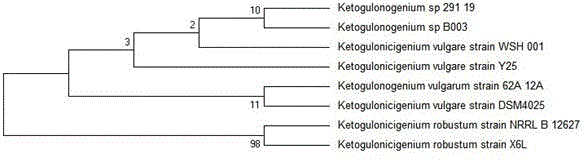

[0036]Genomic DNA of strain SPUB-003 was extracted and PCR amplified with Primer(S): 5'AGA GTT TGA TCC TGG CTC AG 3'; and Primer(A): 5'AAG GAG GTG ATC CAG CCG CA 3' The 16s rRNA gene was purified and sequenced, and the measured sequence was compared with the rRNA homologous sequence in Genbank, and 7 strains with high homology were selected, and the phylogenetic tree of the strain was constructed using the software Mega5. Strain SPUB-003 and Ketogul...

Embodiment 2

[0040] Implementation example 2: strain SPUB-003 shake flask fermentation characteristics

[0041] The purely cultured strain SPUB-003 was inoculated in the basic seed medium, and after 24 hours of shaking flask culture at 30°C and 220rpm, it was inoculated in the basic fermentation medium with a 10% transplantation amount, and the fermentation medium contained 7% of Sorbus Sugar, cultured at 25~34°C, shaking at 220r / min for 72h. Samples were taken every 4 hours, and the strain concentration (OD650 value), pH value, 2-KLG yield and conversion rate were measured at 650nm. The experimental results are shown in Table 2. It can be seen that the conversion rate of strain SPUB-003 was the highest at 32°C for 68 hours, reaching 73.32%.

[0042]

[0043]

[0044]

[0045]

[0046]

Embodiment 3

[0047] Implementation Example 3: Determination of the optimum sorbose concentration fermented by bacterial strain SPUB-003

[0048] The purely cultured strain SPUB-003 was inoculated into the basic seed medium, and after 24 hours of shaking flask culture at 32°C and 220rpm, it was inoculated into the basic fermentation medium with a 10% transfer amount, and the fermentation medium contained 1%~13 % sorbose, cultivated at 32°C with shaking at 220r / min for 68 hours, and controlled the pH to 6.8~7.0 during the fermentation process. After the fermentation, the output and conversion rate of 2-KLG were measured. As shown in Table 3, it can be seen that the optimum sorbose substrate concentration of bacterial strain SPUB-003 is no more than 7%, and the conversion rate can reach 76.20% under this condition; preferred 1 -5%, its conversion rate is more than 85%; more preferably 1-3%, its conversion rate is more than 95%.

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com