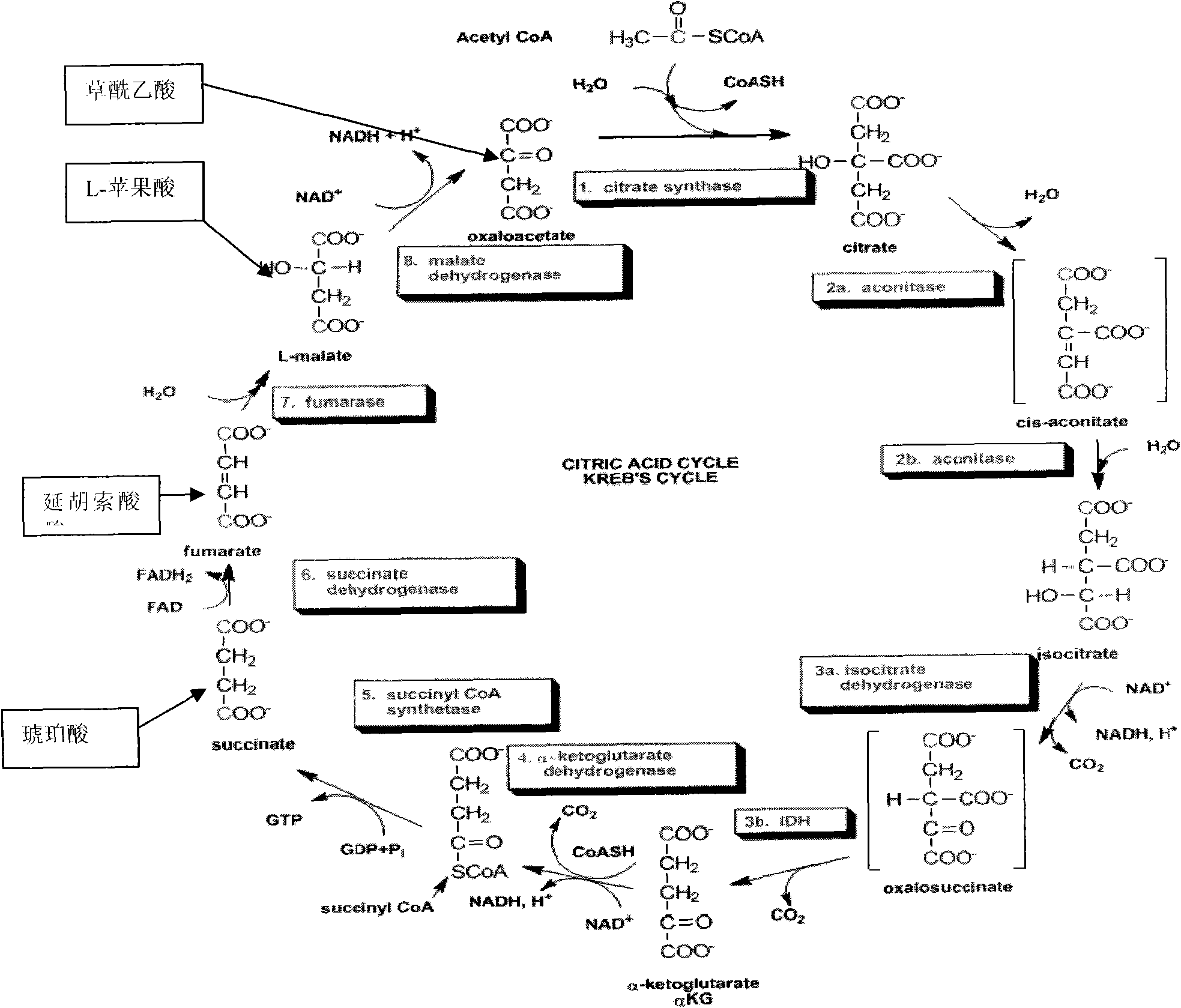

Application of tetra-carbonic acid or salt thereof to preparing 2-keto-L-gulonic acid in tricarboxylic acid cycle

A technology of tricarboxylic acid, gulonic acid, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment one: the preparation (preparation of culture medium) of the nutrient-enhanced corn steep liquor product containing succinic acid

[0084] Step 1: Select corn soaking water with stable quality, the dry matter content of which is not less than 9%, add inorganic flocculant, heat to 65°C-85°C and filter,

[0085] Step 2: using succinic acid to acidify the filtrate so that the succinic acid content reaches 5% (w / w) of the soaking water dry matter,

[0086]Step 3: Vacuum concentration until the dry matter reaches 40%, to obtain a concentrated slurry,

[0087] Step 4: Add succinic acid again to the concentrated pulp to obtain a strengthened pulp with a succinic acid content of 10% (mass volume percentage). When the slurry is fermented with 2-KGA, the usage amount is 1% (in terms of dry matter), and the succinic acid in the culture medium reaches 0.1%.

[0088] In this example, the purification of corn steep liquor is combined with the strengthening of tetracarboni...

Embodiment 2

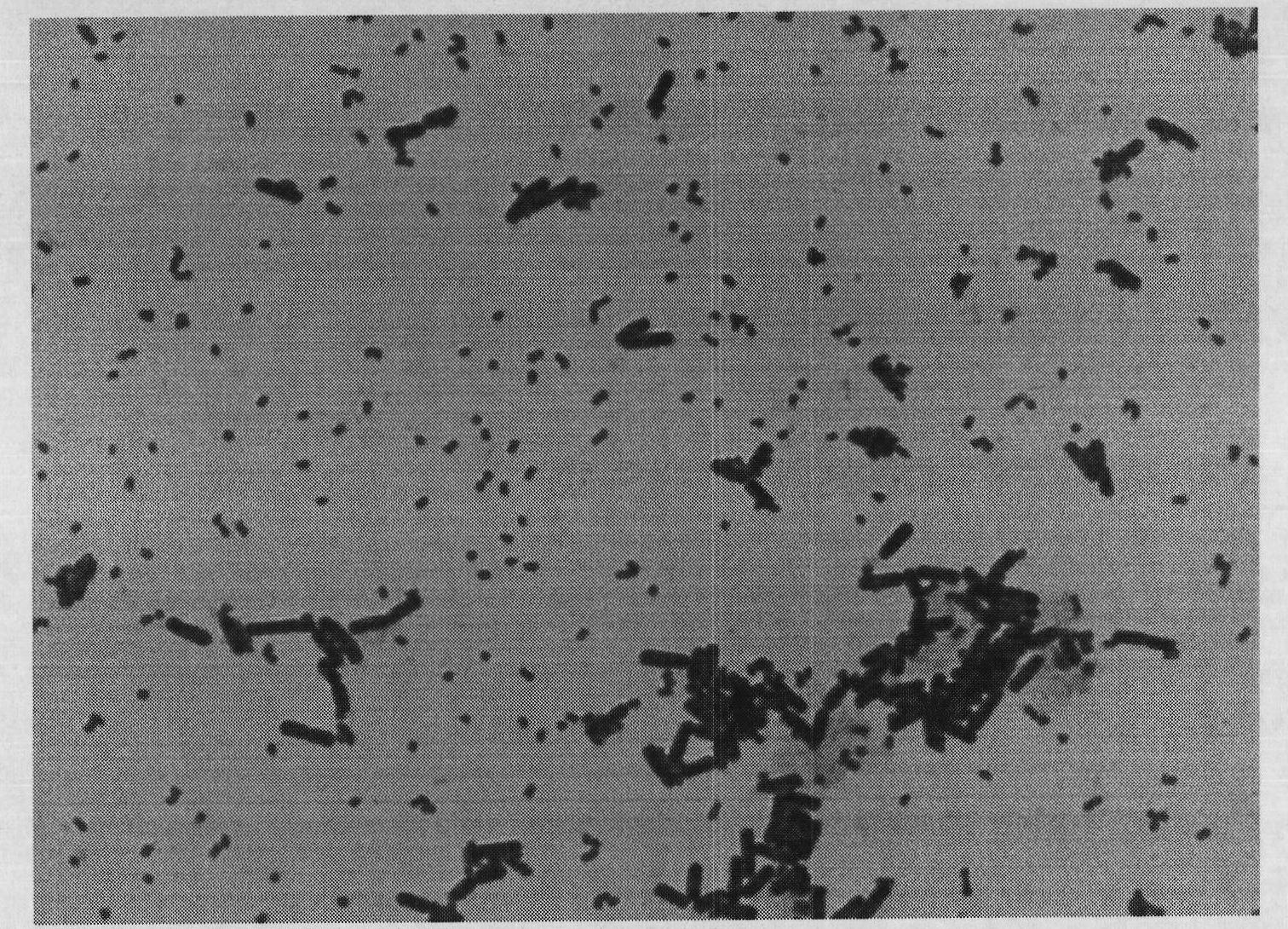

[0090] Embodiment two: Sodium succinate is to the improvement of " two-step fermentation method " technique, bacterial classification adopts large bacterium and small bacterium

[0091] The results of Experiment 2 show that among the four compounds, succinic acid has the most obvious promotion effect on the growth and acid production of small bacteria, so it is used as a representative in the process of fermentation and production of 2-KGA. Since the first step of the "two-step fermentation" process is very mature from sorbitol to sorbose, only the second-step fermentation from sorbose to 2-KGA is used to illustrate the "two-step fermentation" process improvement

[0092] Step 1: The preparation of the culture medium adopts the conventional culture medium preparation method, using sorbose as the substrate:

[0093] 1. Solid medium (mass volume percentage): sorbose 2%, corn steep liquor 1%, yeast powder 1%, urea 1%, potassium dihydrogen phosphate 0.1%, ammonium sulfate 0.1%, s...

Embodiment 3

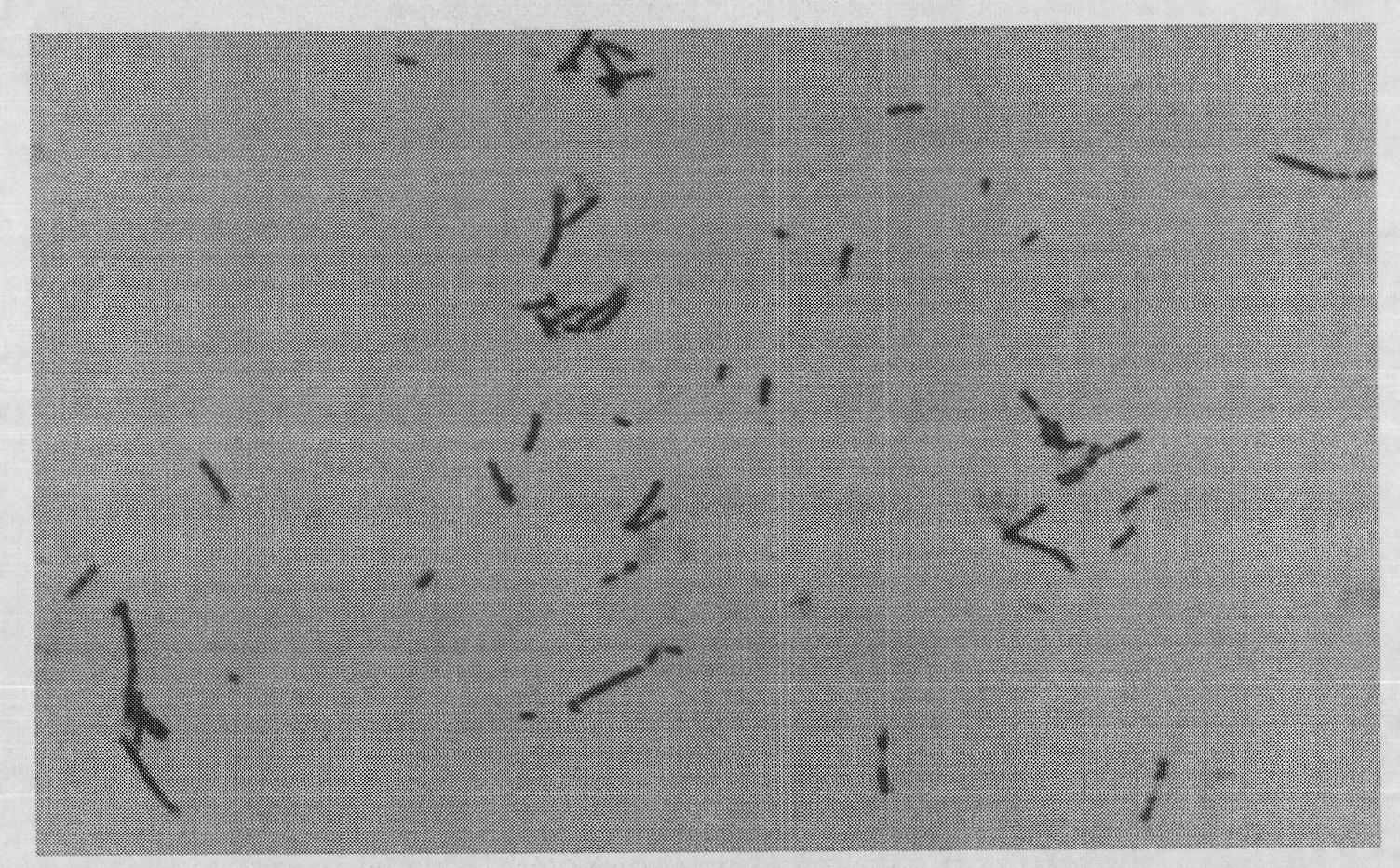

[0104] Embodiment 3: Using sodium succinate to establish a "pure fermenting process" from sorbose to 2-KGA, the bacterial species adopts small bacteria

[0105] Step 1, the preparation of culture medium, is the same as embodiment 2.

[0106] Step 2, conventional sterilization of the culture medium is the same as in Example 2.

[0107] Step 3: 10-liter fermenter, sterilized by steam for 30 minutes, liquid medium, 121 ° C, sterilized for 25 minutes, sorbose, urea and other medium components were sterilized separately.

[0108] Step 4: Make the small bacteria grown on the solid medium into a bacterial suspension, take 5ml and insert it into the seed medium, the liquid volume is 75ml / 500ml, 28°C-30°C, shaker speed 180-200rpm, cultivate for 18-20h , made into liquid seeds.

[0109] Step 5, liquid seeds, 5% inoculum amount is inserted into a 10L fermenter, 28°C-30°C, 250-300rpm, sodium hydroxide automatically adjusts the pH to 7.2, and cultivates for 48h.

[0110] Step 6: Separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com