Gas supply system of natural gas single-fuel engine

A gas supply system and engine technology, applied to combustion engines, internal combustion piston engines, charging systems, etc., can solve problems such as automatic adjustment of the mixture, failure to ensure the mixture of the mixture, and the engine's inability to mix gas and air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

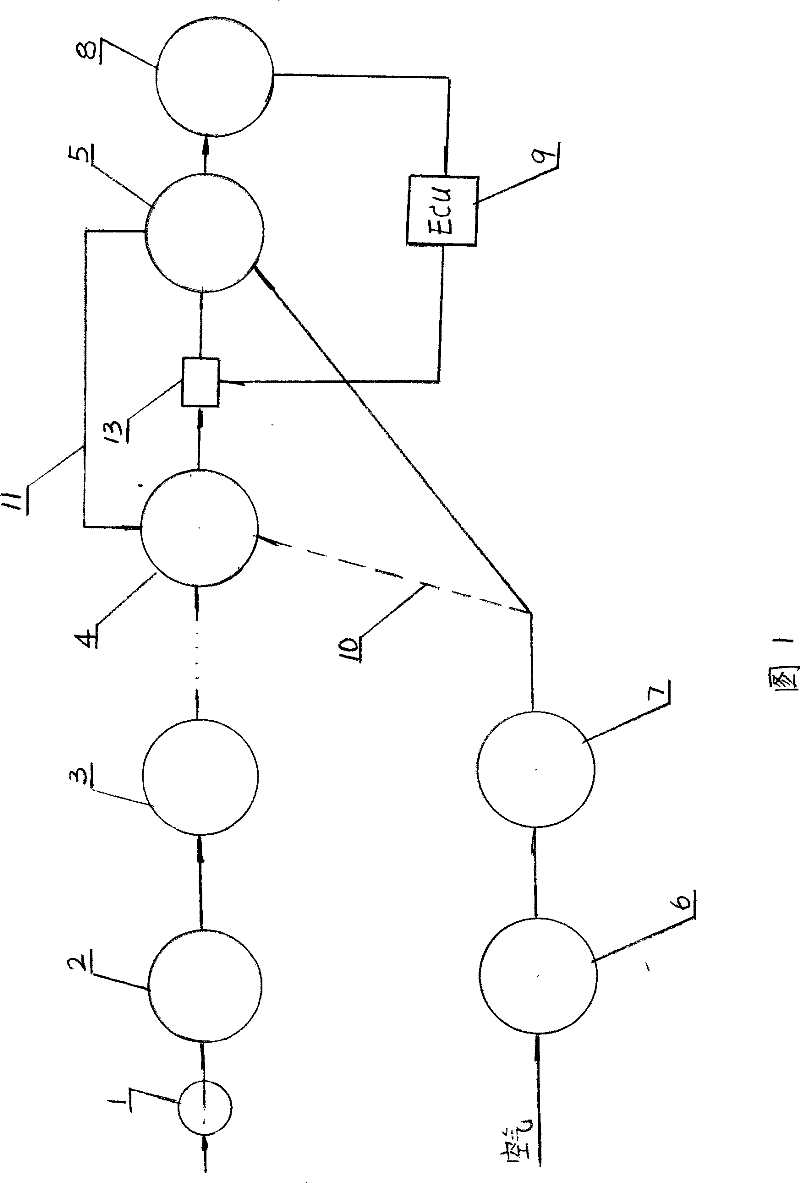

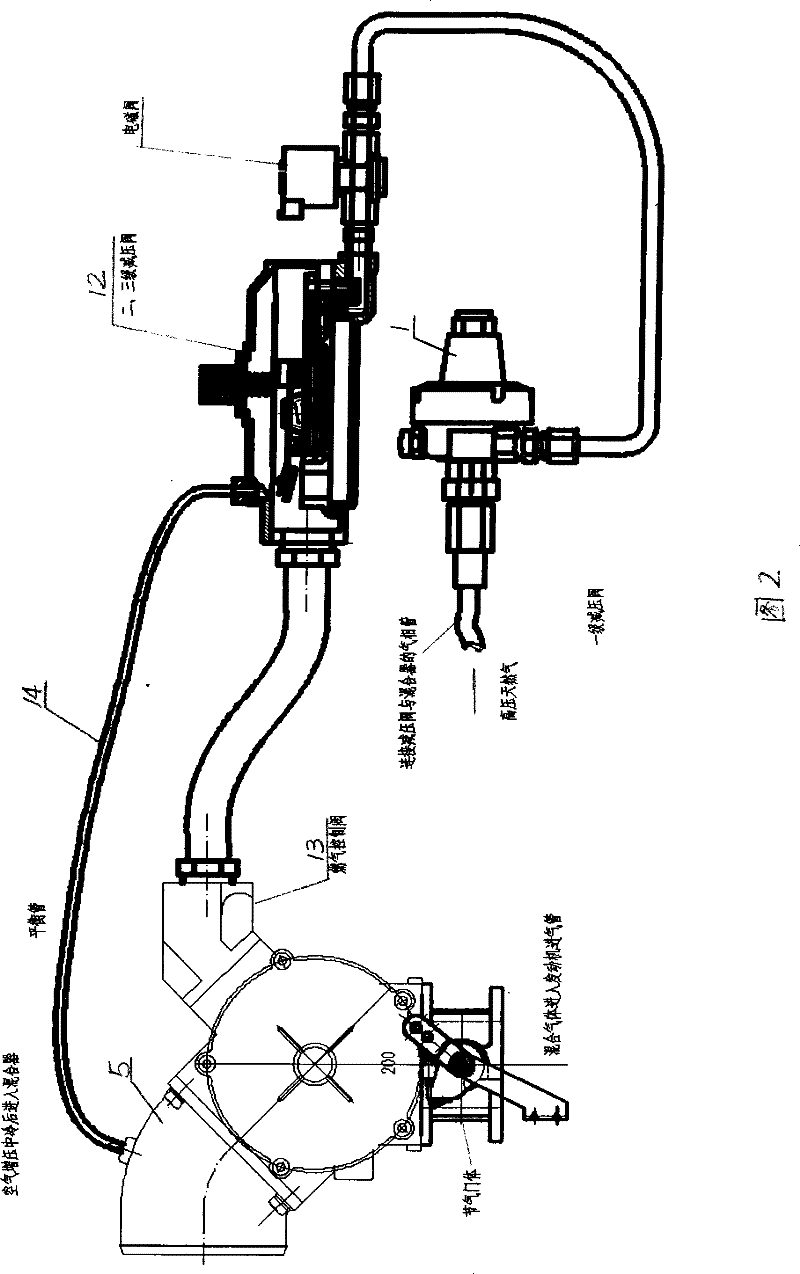

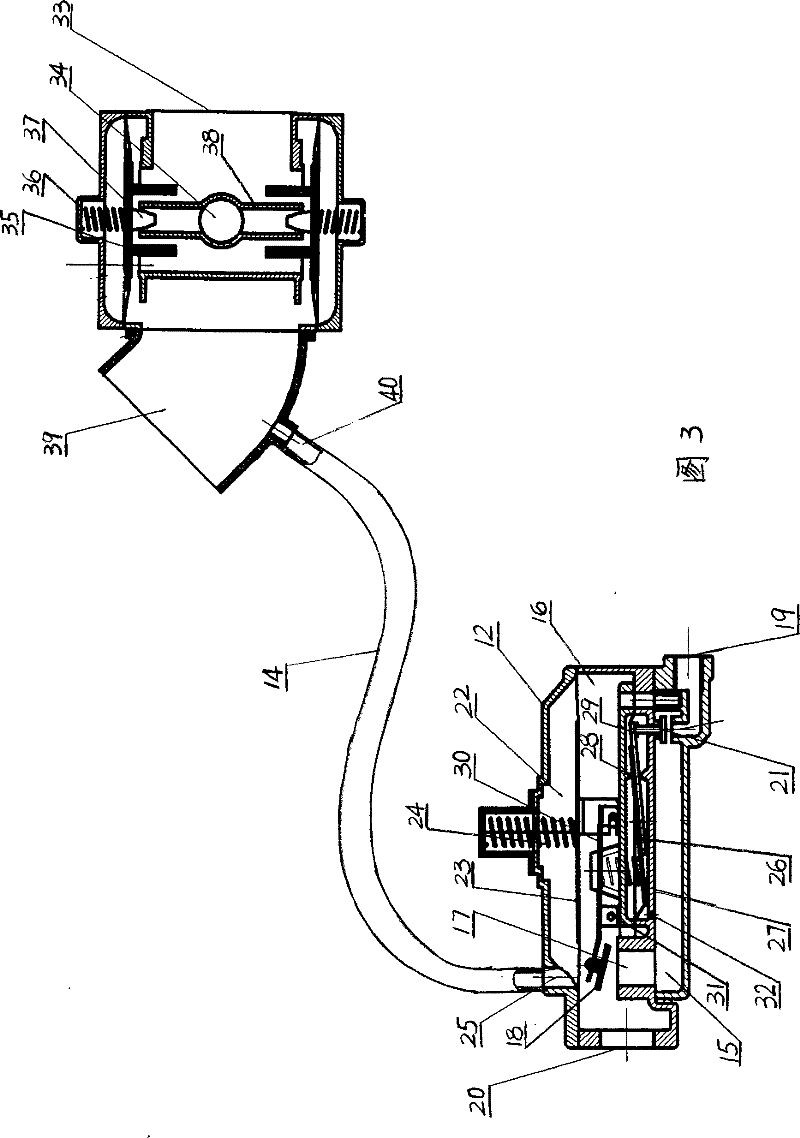

[0011] Such as figure 1 In the system block diagram shown, the high-pressure natural gas in the steel cylinder enters the high-pressure reducer 1 through the pipeline → the second-stage reducer 2 → the third-stage reducer 3 ... the final-stage reducer 4, and the final-stage reducer 4 enters the mixer There is an air supply valve 13 directly between the 5, and the other branch enters the exhaust gas supercharging turbine 6 from the air → cools through the intercooler 7 → enters the mixer 5, and the gas outlet of the mixer 5 enters the engine cylinder 8, and the system is connected with Two branches, one belongs to the ECu control system of known technology, ECu is indicated by subscript 9, and the other branch is designed for the solution of the present invention, which can be directly connected to the final stage pressure reducer through the branch 10 from the intercooler 4. Use a dotted line to indicate that this is a conceivable connection. The specific connection is from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com