Display panel and manufacturing method thereof, display device and color reproduction method thereof, and electronic device

A display panel and display device technology, which is applied to electronic equipment, display devices and their color reproduction, display panels and their manufacturing fields, can solve the problems of increasing manufacturing process costs, scrapping, and failure to restore the original state, so as to reduce production costs, The effect of reducing manufacturing precision and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The following is attached Figure 3 to Figure 12 An embodiment of the display panel is described in detail.

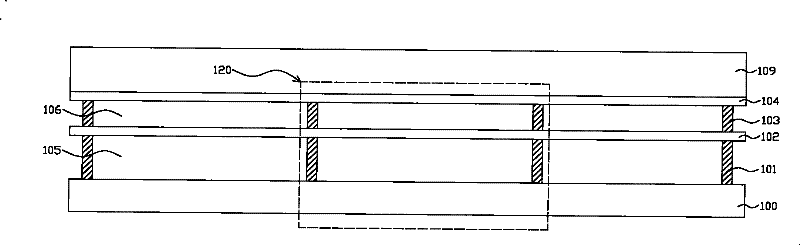

[0085] image 3 It is a schematic diagram of the structure of the display panel. A dotted line on the display panel represents a pixel 120 displaying a color, and an array of a plurality of such pixels displaying a color is arranged repeatedly to form a display panel. The display panel includes: a substrate 100, a first support layer 101 on the substrate 100, a first reflective layer 102 on the first support layer 101, a second support layer 103 on the first reflective layer 102, and a second support layer 103 A transparent film layer 109 coated with a translucent second reflective layer 104; the first support layer 101 separates the first gap 105 between the substrate 100 and the first reflective layer 102; the second support layer 103 will A second gap 106 is separated between the second reflective layer 104 and the first reflective layer 102 ; the transpar...

Embodiment 2

[0131] Figure 13 It is a schematic diagram of the display device described in this embodiment, including: a control unit 201, and a display panel 202; wherein, the control unit 201 is used to drive the display panel 202 and transmit data signals received from the outside of the display device to the display panel 202; the display panel 202 is used to display images according to the received data signal under the drive of the control unit 201. The display panel 202 may be any display panel in Embodiment 1, which will not be repeated here.

[0132] The control unit 201 is composed of a source driver integrated circuit and an address driver integrated circuit (not shown in the figure). The source driver integrated circuit is connected to the source of each TFT of the pixel array on the display panel through a data line, thereby transmitting a data signal to the pixel; and the address driver integrated circuit is connected to each TFT of the pixel array on the display panel thro...

Embodiment 3

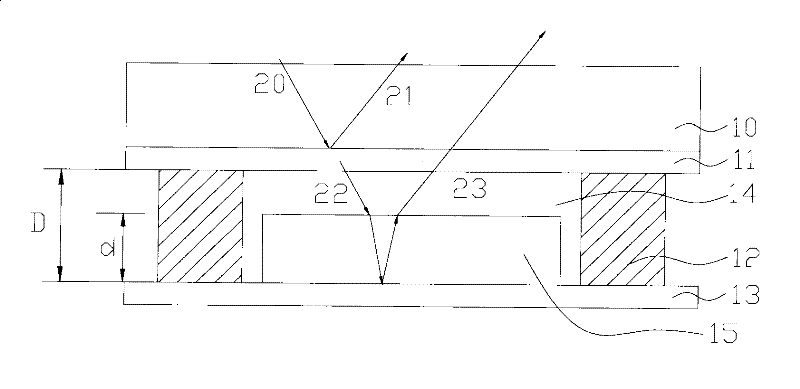

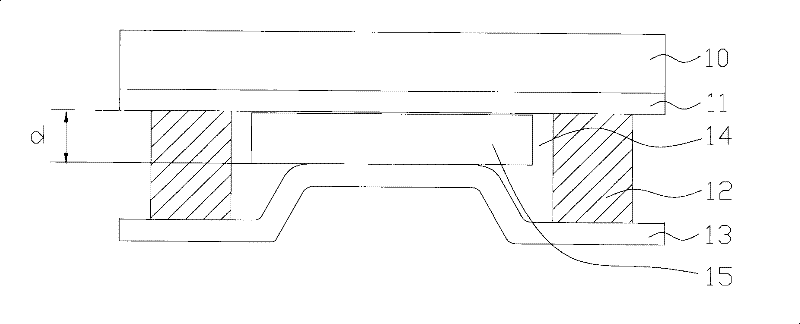

[0143] Figure 15 It is a schematic structural diagram of the display panel described in Embodiment 1. Figure 16 to Figure 18 It is a schematic diagram of embossing the first reflective layer in this embodiment. The figure only shows a schematic diagram of embossing one reflective unit in the first reflective layer. In this embodiment, the manufacturing method of the provided display panel is described in detail by taking the manufacturing of the display panel mentioned in the first embodiment as an example. Described method specifically comprises:

[0144] Step A: If Figure 15 As shown, a substrate 100 is provided; the substrate 100 can be a driving substrate with a display driving circuit pattern engraved in advance, or a ready-made driving substrate of an active matrix liquid crystal display (AMLCD). The substrate 100 is provided with an electrode array and wiring. If the active matrix liquid crystal display substrate 100 is used, the substrate is provided with an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com