Method for molding rare earth absorbent

A molding method and adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as easy loss, large hydraulic resistance, and difficult recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

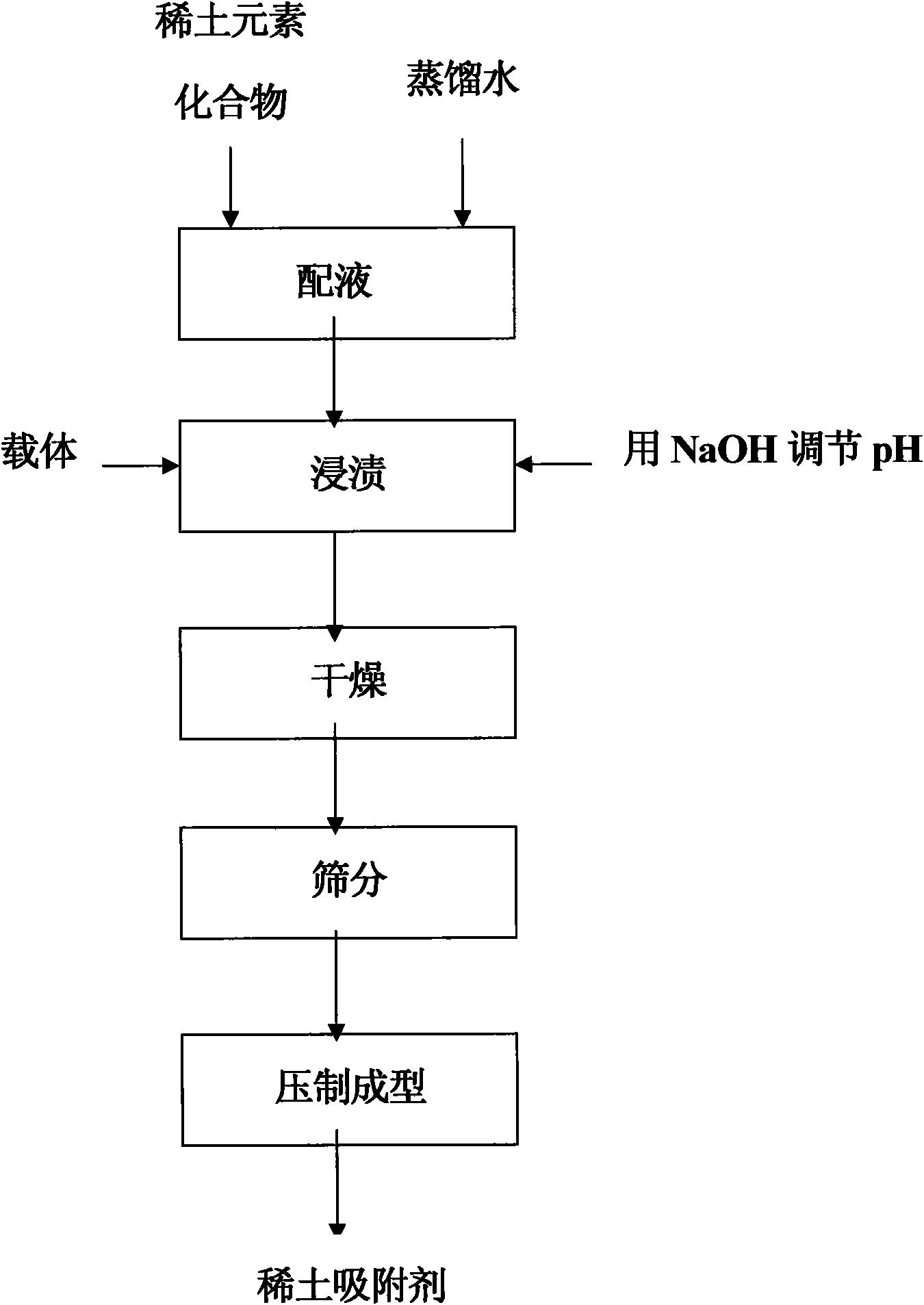

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: cerium nitrate is dissolved in distilled water, is made into the solution that cerium ion is 0.7% by mass fraction, adjusts pH with sodium hydroxide solution to be 10, now has cerium hydroxide to generate in the solution; Particle diameter is 100 ~130 mesh 4A zeolite, soak in 0.1mol / L sodium hydroxide solution for 1 hour, wash repeatedly with distilled water several times after soaking, then soak in 0.1mol / L hydrochloric acid solution for 1 hour, wash repeatedly with distilled water for several times after soaking Finally, soak in distilled water for 1 hour, filter and dry at 120°C for 12 hours; after activation, add it into the prepared cerium hydroxide solution according to the solid-liquid ratio of 1:50, stir at room temperature for more than 16 hours, filter After drying the filter cake for 12 hours, the powdered rare earth adsorbent was prepared; the powdered rare earth adsorbent was initially granulated with polyvinyl alcohol, and pressed after obtain...

Embodiment 2

[0019] Embodiment 2: lanthanum chloride is dissolved in distilled water, is made into the solution that lanthanum ion is 0.8% by mass fraction, adjusts pH with sodium hydroxide solution and is 11, now has lanthanum hydroxide to generate in the solution; Raw material is particle diameter For 4A zeolite of 100-130 mesh, soak in 0.1mol / L sodium hydroxide solution for 1 hour, wash repeatedly with distilled water several times after soaking, then soak in 0.1mol / L hydrochloric acid solution for 1 hour, soak with distilled water repeatedly Wash several times, and finally soak in distilled water for 1 hour, filter and dry at 110°C for 12 hours; after activation, add it to the prepared lanthanum hydroxide solution according to the solid-to-liquid ratio of 1:50, and stir at room temperature for more than 20 hours After filtration, the filter cake was dried for 12 hours to obtain a powder rare earth adsorbent; the powder rare earth adsorbent was initially granulated with polyvinyl alcohol...

Embodiment 3

[0021] Embodiment 3: lanthanum chloride is dissolved in distilled water, is made into the solution that lanthanum ion is 0.75% by mass fraction, adjusts pH to be 10 with sodium hydroxide solution, has lanthanum hydroxide to generate in this moment in solution; Raw material is particle diameter Diatomaceous earth of 60-80 mesh, soaked in 0.1mol / L sodium hydroxide solution for 1 hour, washed repeatedly with distilled water several times after soaking, then soaked in 0.1mol / L hydrochloric acid solution for 1 hour, soaked in distilled water Repeated washing several times, finally soaked in distilled water for 1 hour, filtered and dried at 110°C for 12 hours; after activation, added to the prepared lanthanum hydroxide solution according to the solid-to-liquid ratio of 1:50, and stirred at room temperature for 18 hours Above, after filtration, the filter cake was dried for 12 hours to obtain a powder rare earth adsorbent; the powder rare earth adsorbent was initially granulated with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com