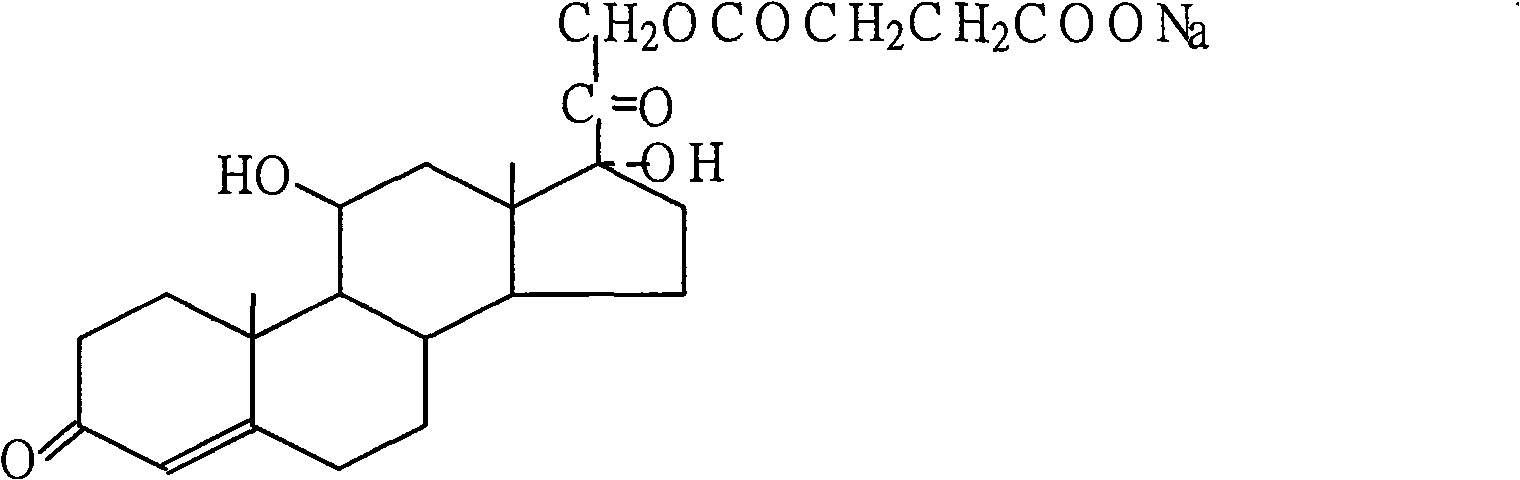

Method for preparing hydrocortisone sodium succinate

A technology of hydrocortisone sodium succinate and pine succinic acid, applied in the field of medicinal chemistry, can solve the problems of increased process complexity, small production scale, high drying cost, stable product quality, stable reaction process, and reduced production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of hydrocortisone succinic acid monoester: put 1Kg of hydrocortisone and 1.9kg of dimethylformamide into a dry reaction tank, stir to dissolve at 20-25°C. Open interlayer brine and cool down to 10±1°C, add 0.22Kg triethylamine, then slowly add 0.8Kg succinic anhydride, control the temperature at 15±1°C for 3.5 hours. Dilute it in 15Kg of purified water cooled to 2°C while stirring, let it stand at 5-8°C for 3 hours, filter and discharge, the refined product is white powder, and the yield is 95.2%.

Embodiment 2

[0016] Synthesis of hydrocortisone sodium succinate: 50 g of hydrocortisone succinate monoester was obtained by the method in Example 1, added into 200 ml of purified water at a dissolving temperature of 0-10° C., and stirred for about 50 minutes to dissolve completely. Add 9g of sodium bicarbonate, slowly add a proportion of acetone 100ml, add dropwise at a rate of about 2ml / min, after the dropwise addition, control the temperature at 0-10°C, keep warm for 2h, gradually dissolve, add 2.5g of charcoal, and decolorize for 30min , filter with filter bucket, concentrate under reduced pressure, T≤30℃, vacuum should be ≤-0.08MPa, concentrate to 46.32g of hydrocortisone sodium succinate, the color is white or off-white powder. The yield is 92.64%, and the melting point is 170℃ .

Embodiment 3

[0018] Synthesis of hydrocortisone sodium succinate: 50 g of hydrocortisone succinate monoester was obtained by the method in Example 1, added into 165 ml of purified water at a dissolving temperature of 10-20° C., and stirred for about 40 minutes to dissolve completely. Add 4.3g of sodium hydroxide, slowly add a proportioning amount of acetone 100ml, add dropwise at a rate of about 2ml / min, after the dropwise addition, control the temperature at 10-20°C, keep warm for 1.5h, gradually dissolve, add 2.5g of charcoal, Decolorize for 30 minutes, filter with filter funnel, concentrate under reduced pressure, T≤30℃, vacuum should be ≤-0.08MPa, concentrate to 45.86g of hydrocortisone sodium succinate, the color is white or off-white powder. The yield is 91.72%, melting point 170°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com