Method for de-coloring soybean polysaccharide

A soybean polysaccharide and decolorization technology, which is applied in the field of food additives, can solve the problems of low decolorization efficiency, high protein impurities, and product quality decline, and achieves the effect of good pigment removal effect, simplified treatment process and less impurity protein content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

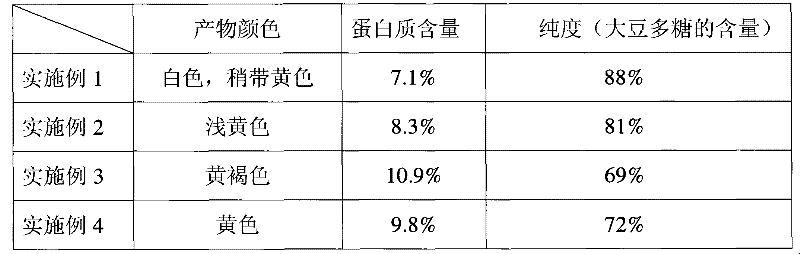

Examples

Embodiment 1

[0031] The decolorization treatment of embodiment 1 ion exchange resin

[0032] The soybean okara of the present embodiment is commercially available.

[0033] Take 600 g of MN200 ultra-large mesh anion exchange resin (commercially available), pretreat it with sodium hydroxide, and then pack it into a column. The aspect ratio of the ion column is 5:1.

[0034] In this embodiment, ion exchange resin is used to decolorize soybean polysaccharide extract, and the specific steps are as follows:

[0035] (1) After adding water to soybean dregs and fully stirring for half an hour, centrifuge to remove the supernatant, add water to the centrifuged sediment to adjust the pH value of the whole system to 5.0 (when the pH of the system is adjusted to 5.0, it is helpful for the cellulase Reaction), adding cellulase for enzyme treatment, the time is 1h. After the enzyme treatment step, adjust the pH value of the whole system to 8.0, adjust the temperature to 100-100°C, and keep it for 1.5...

Embodiment 2

[0038] The decolorization treatment of embodiment 2 ion exchange resins

[0039] The soybean okara of the present embodiment is commercially available.

[0040] Take 600 g of A850 ion-exchange resin produced by Brilliant (China) Co., Ltd., pretreat it with sodium hydroxide, and then pack it into a column. The height-to-diameter ratio of the ion column is 7:1.

[0041] In this embodiment, ion exchange resin is used to decolorize soybean polysaccharide extract, and the specific steps are as follows:

[0042] (1) After adding water to the soybean dregs and stirring thoroughly for half an hour, centrifuge to remove the supernatant, add water to the centrifuged sediment to adjust the pH of the whole system to 5.0, and add cellulase for enzyme treatment for 1 hour. After the enzyme treatment step, adjust the pH value of the whole system to 8.0, adjust the temperature to 100-100°C, and keep it for 1.5h for heat extraction to obtain soybean polysaccharide extract;

[0043] (2) Get a...

Embodiment 3

[0045] The decolorization treatment of embodiment 3 gac

[0046] The soybean okara of the present embodiment is commercially available.

[0047] In this embodiment, activated carbon is used to decolorize the soybean polysaccharide extract, and the specific steps are as follows:

[0048] (1) After adding water to the soybean dregs and stirring thoroughly for half an hour, centrifuge to remove the supernatant, add water to the centrifuged sediment to adjust the pH of the whole system to 5.0, and add cellulase for enzyme treatment for 1 hour. After the enzyme treatment step, adjust the pH value of the whole system to 8.0, adjust the temperature to 100-100°C, and keep it for 1.5h for heat extraction to obtain soybean polysaccharide extract;

[0049] (2) Get the above-mentioned soybean polysaccharide extract 500ml and pass through the diatomite layer, the consumption of diatomite is 5g, then it is decolorized with activated granular activated carbon, the consumption of granular ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com