Dyeing method of alkali-resistant dispersed dye used by dacron ultrafine fiber

A polyester microfiber and disperse dye technology, which is applied in the field of textile dyeing and finishing, can solve the problems of fabric tar spots, large pollution discharge, and high processing water consumption, and achieve the reduction of total waste water discharge, shortening of process flow, and reduction of energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

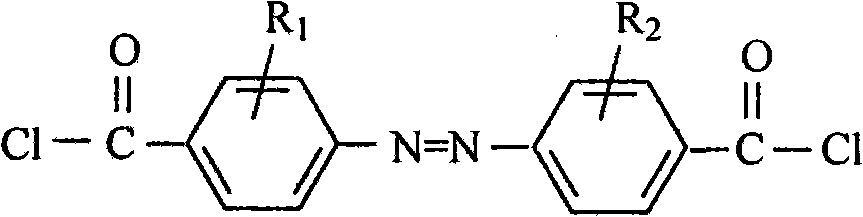

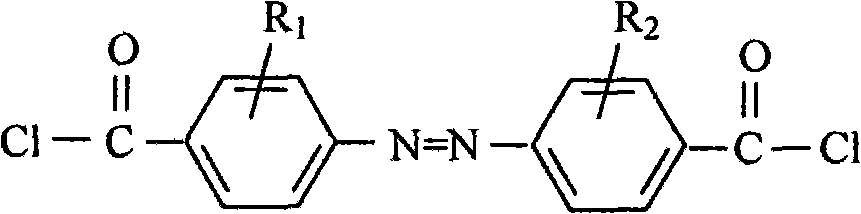

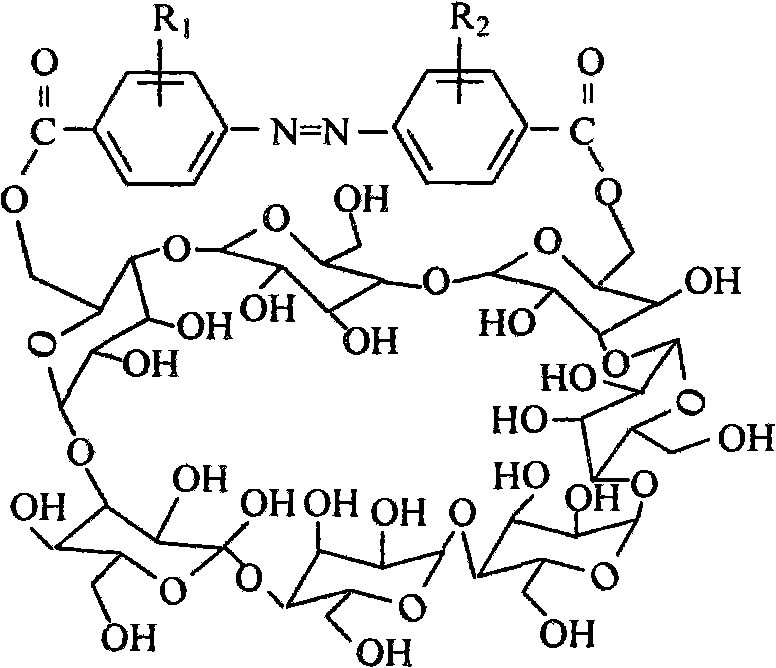

[0052] In the 500ml flask, add 4,4'-formyl chloride azobenzene (that is: azobenzene-4,4'-dicarbonyl chloride) 30.7g and distilled water 100g, adjust the pH value of the solution to 9.5 with sodium hydroxide, in Stir in a high-shear machine, slowly add 6g of castor oil polyoxyethylene (24) ether, emulsify for 15min, heat up to 70°C after adding, then slowly add β-cyclodextrin 113.5g, keep at 70°C for 2 Hours, after the reaction is completed, it is filtered, washed and dried to obtain the azocyclodextrin pre-condensed body. Adjust the pH of the azocyclodextrin precondensate to 8, add 31.6g of disperse dye C.I. Disperse Yellow 11 to the azocyclodextrin precondensate, control the temperature at 40°C, stir at high speed while adding, and stir evenly , filtered under reduced pressure, washed and dried to obtain an alkali-resistant disperse dye complexed with azocyclodextrin. Adjust the pH of the alkali-resistant disperse dye complexed with azocyclodextrin to 7, and slowly add 8.6 g...

Embodiment 2

[0056] Add 2,2'-dimethyl-4,4'-formyl chloride azobenzene 34.0g and distilled water 100g in a 500ml flask, adjust the pH value of the solution to 10.0 with sodium hydroxide, stir in a high shear machine, Slowly add 7g of lauryl polyoxyethylene (7) ether, emulsify for 20min, heat up to 80°C after adding, then slowly add 129.7g of γ-cyclodextrin, keep at 80°C for 2.5 hours, after the reaction is completed, filter, After washing and drying, the azocyclodextrin precondensate is obtained. Adjust the pH value of the azocyclodextrin precondensate to 8, and add 31.5g of the monoazoheterocyclic blue alkali-resistant disperse dye in the Chinese patent application whose application number is 200910099854.9 to the azocyclodextrin precondensate (application number is the disperse dye that the structural formula disclosed in the Chinese patent application of 200910099854.9 is shown in formula (I), and molecular formula is C 18 N 6 o 2 h 18 ), control the temperature at 40°C, stir at high...

Embodiment 3

[0061] Add 30.7g of 4,4'-formylchloroazobenzene and 100g of distilled water into a 500ml flask, adjust the pH value of the solution to 9.5 with sodium hydroxide, stir in a high shear machine, and slowly add 6g of lauryl glycol Ether, emulsified for 20min, heated up to 75°C after adding, then slowly added 124.8g of β-cyclodextrin, kept at 75°C for 2.5 hours, after the reaction was completed, filtered, washed and dried to obtain azocyclodextrin pre- shrinkage. Adjust the pH of the azocyclodextrin precondensate to 8, add 296.1g of C.I. Disperse Red 73 disperse dye to the azocyclodextrin precondensate, control the temperature at 50°C, stir at high speed while adding, and stir evenly , filtered under reduced pressure, washed and dried to obtain an alkali-resistant disperse dye complexed with azocyclodextrin. Adjust the pH of the alkali-resistant disperse dye complexed with azocyclodextrin to 7.5, slowly add 7.6 g of 1815 nonionic surfactant and 10.0 g of diffusing agent NNO at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com