Sand-protecting barrier made from biodegradable materials and preparation method thereof

A technology of biodegradable materials and configuration methods, applied in the field of sand barriers, sand barriers and their configuration, can solve the problems of secondary pollution, troubled large-scale promotion and application, etc., and achieve the effects of preventing sand and soil loss, simplifying construction and reducing transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

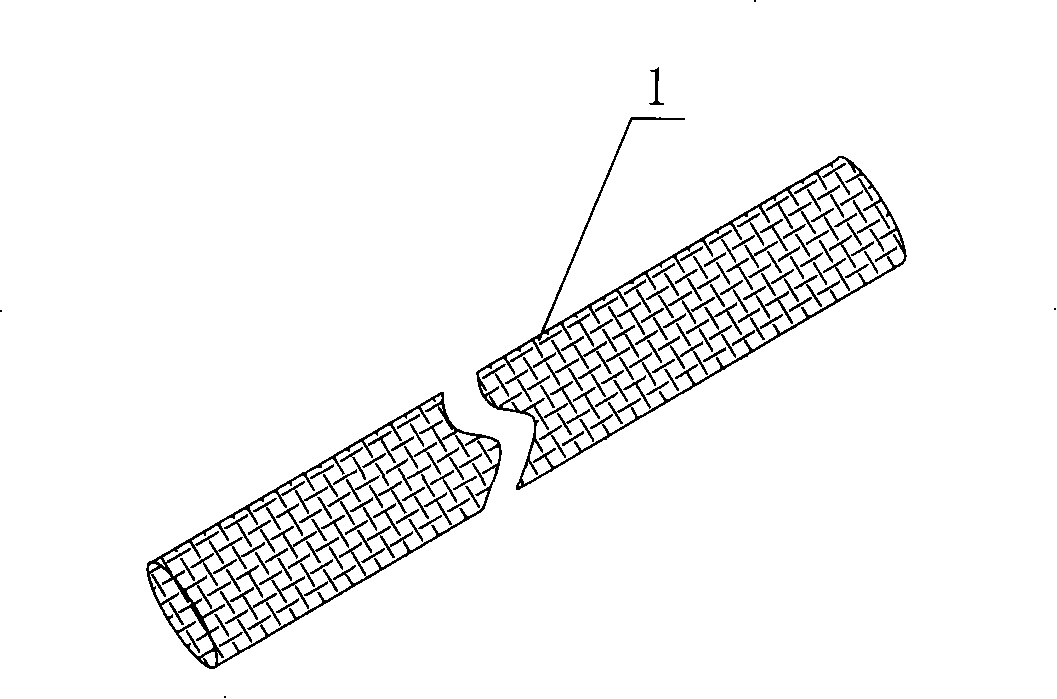

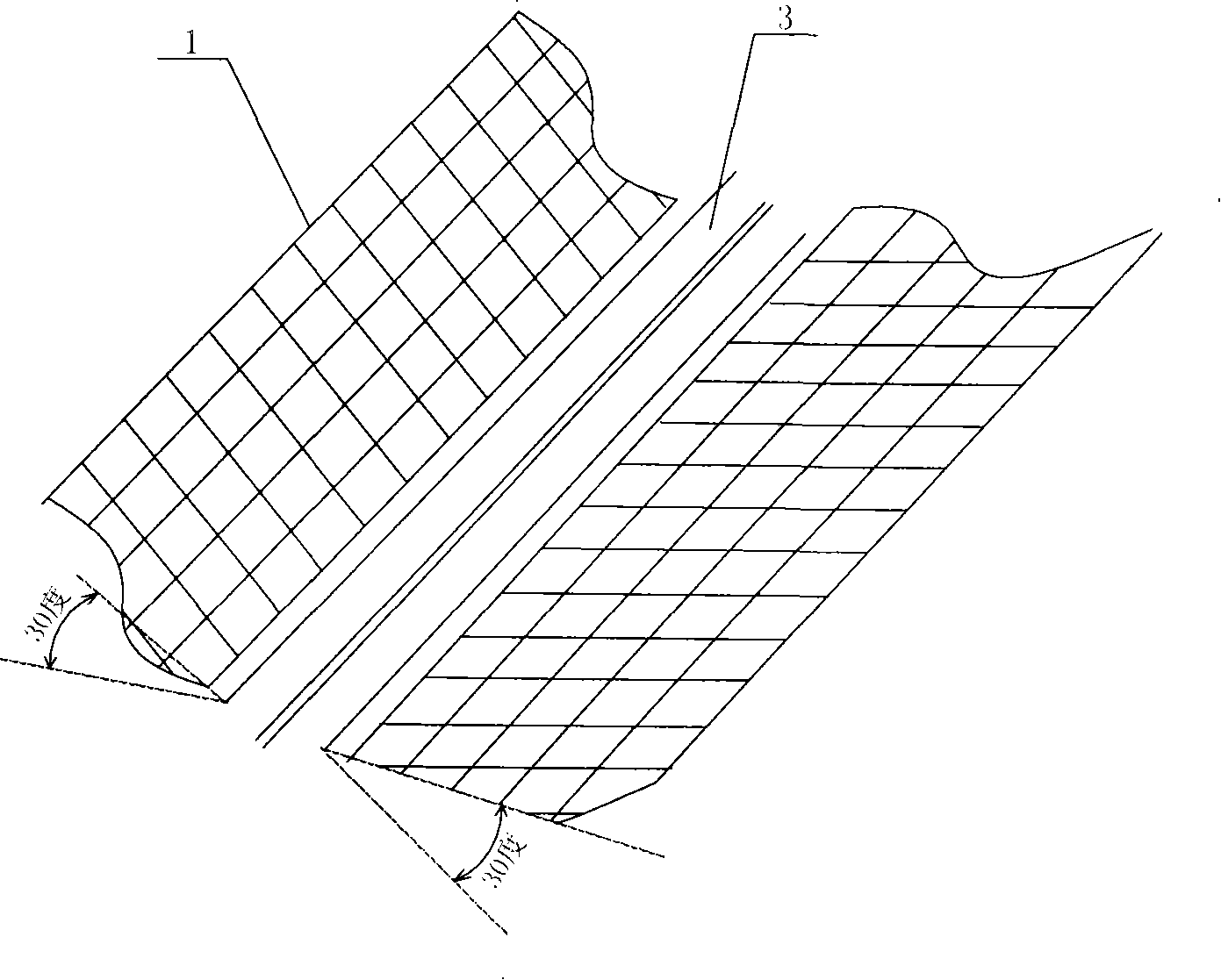

[0044]Embodiment 1: In the section where sand fixation is required on both sides of the road 3, the tiled sand barrier 1 made of polylactic acid fiber (PLA) adopts the tiled configuration method, and the tiled sand barrier 1 fabric is transported to the preset place for use Fill the sand funnel with sand to make it full in the natural state, and lay it flat on the preset ground. At this time, the height of the flat sand barrier 1 is the diameter of the cylinder, but limited by the actual gravity and other conditions, the flat sand barrier 1 The height of the barrier 1 will be slightly smaller than the diameter of the cylinder. The direction of the tiled sand barrier 1 is determined according to the direction of the local major wind. If there are two or more harmful wind directions, the grid configuration method is required. The grid size is preferably 1m×1m or 1m×2m or 2m×2m. If the spacing is too small, the cost will be increased, and if the spacing is too large, the protectio...

Embodiment 2

[0045] Embodiment 2: In the areas where sand fixing is required on both sides of the road 3, the tiled configuration method is adopted. After the tiled sand barrier 1 fabric is transported to the preset site, some psammophyte seeds are loaded while sand is loaded using the sand funnel. , after the tiled sand barrier 1 reaches saturation in the natural state, it is tiled on the preset ground. At this time, the height of the tiled sand barrier 1 is the diameter of the cylinder. The height of the type sand barrier 1 will be slightly smaller than the diameter of the cylinder. The direction of the flat sand barrier 1 is determined according to the direction of the local main wind. If there are two or more major wind directions in this area, the layout method needs to be adopted. The spacing of the layout method can be preferably 1m×1m or 1m×2m or 2m×2m. If the spacing is too small, the cost will be increased. Too much impact on the protective effect, because the seeds of psammophyt...

Embodiment 3

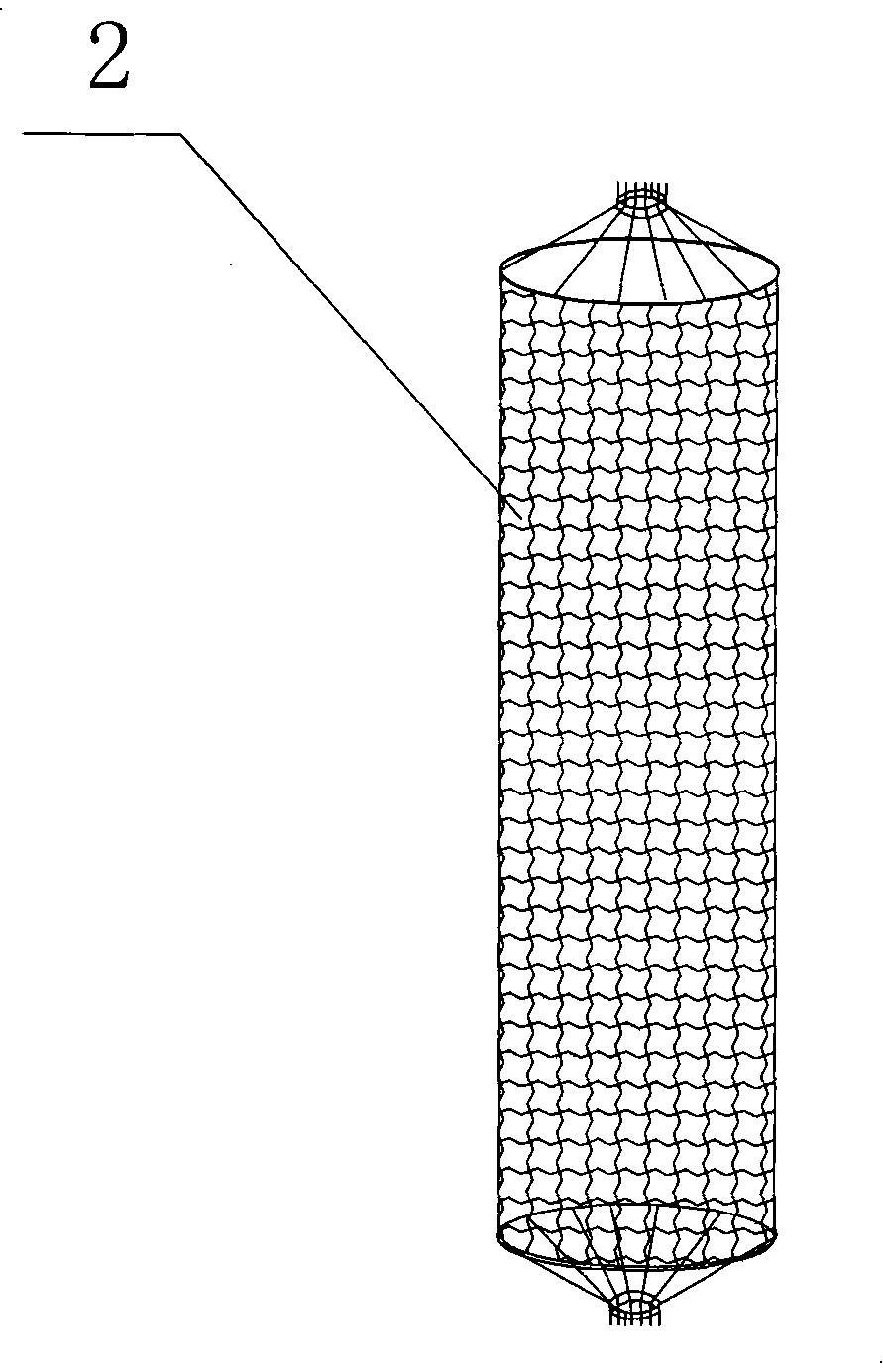

[0046] Embodiment 3: the low vertical sand barrier 2 fabric is transported to the preset location, the low vertical sand barrier 2 requires that the sand dune slope cannot exceed 30°, and the low vertical sand barrier 2 is filled with sand using an sand funnel to make it Reach the fullness in the natural state and knot the two ends of the low vertical sand barrier 2, and stand vertically on the preset ground. At this time, the height of the low vertical sand barrier 2 is the length of the cylinder minus the length of the knotted ends , the height of the low vertical sand barrier 2 is set to 15-30cm, and the fabric gap of the low vertical sand barrier 2 is suitable for no sand leakage. If there is only one major wind in one direction in a year, the row configuration method can be used. If there are two or more major wind directions in the area, the format configuration method should be used. The distance between the low vertical sand barriers 2 is based on the actual natural If...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com