Indoor-laying optical fiber

An optical fiber, bare fiber technology, applied in clad optical fiber, optical waveguide light guide, glass manufacturing equipment, etc., to achieve the effect of reducing manufacturing cost, tight integration, and thin diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

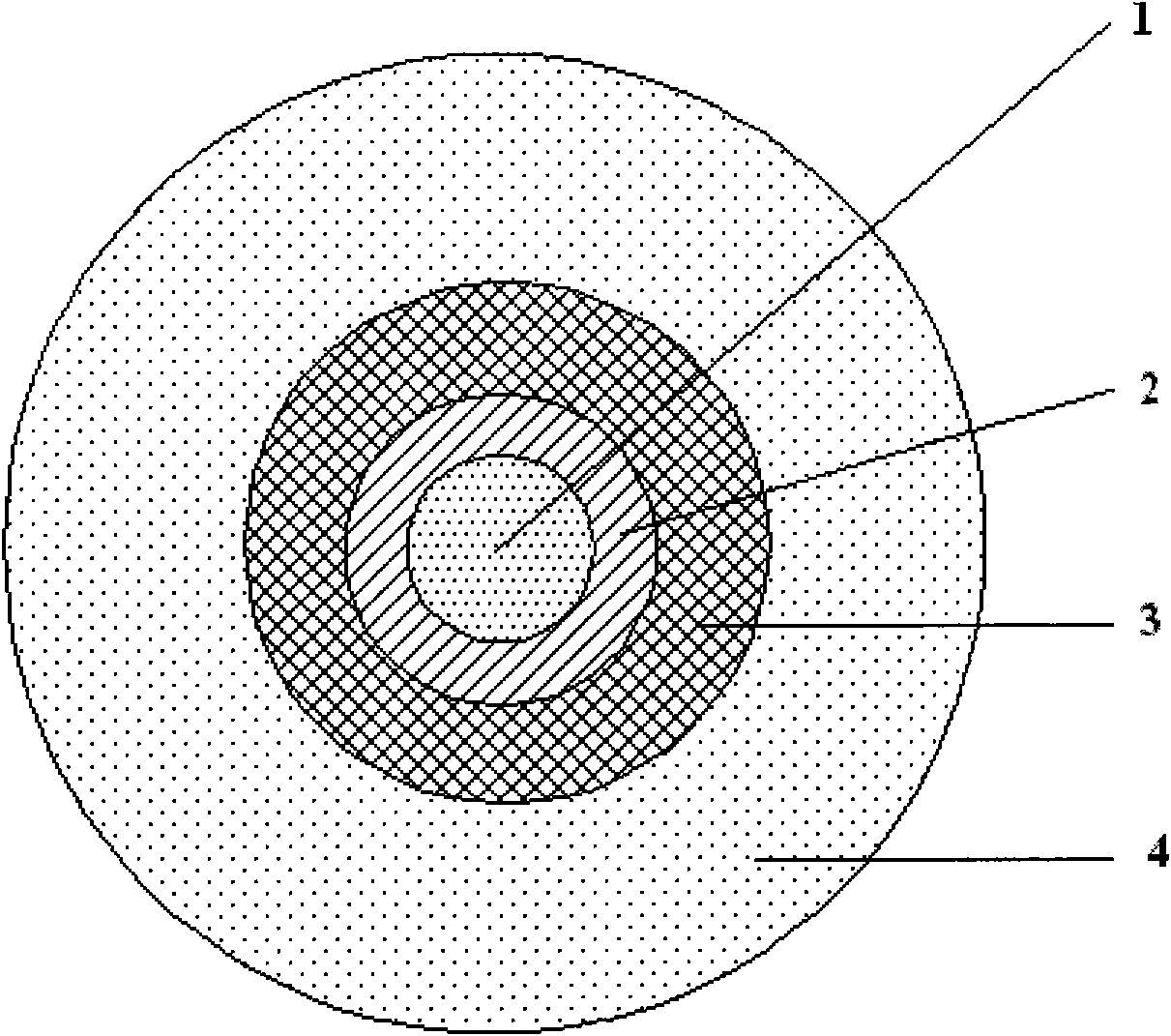

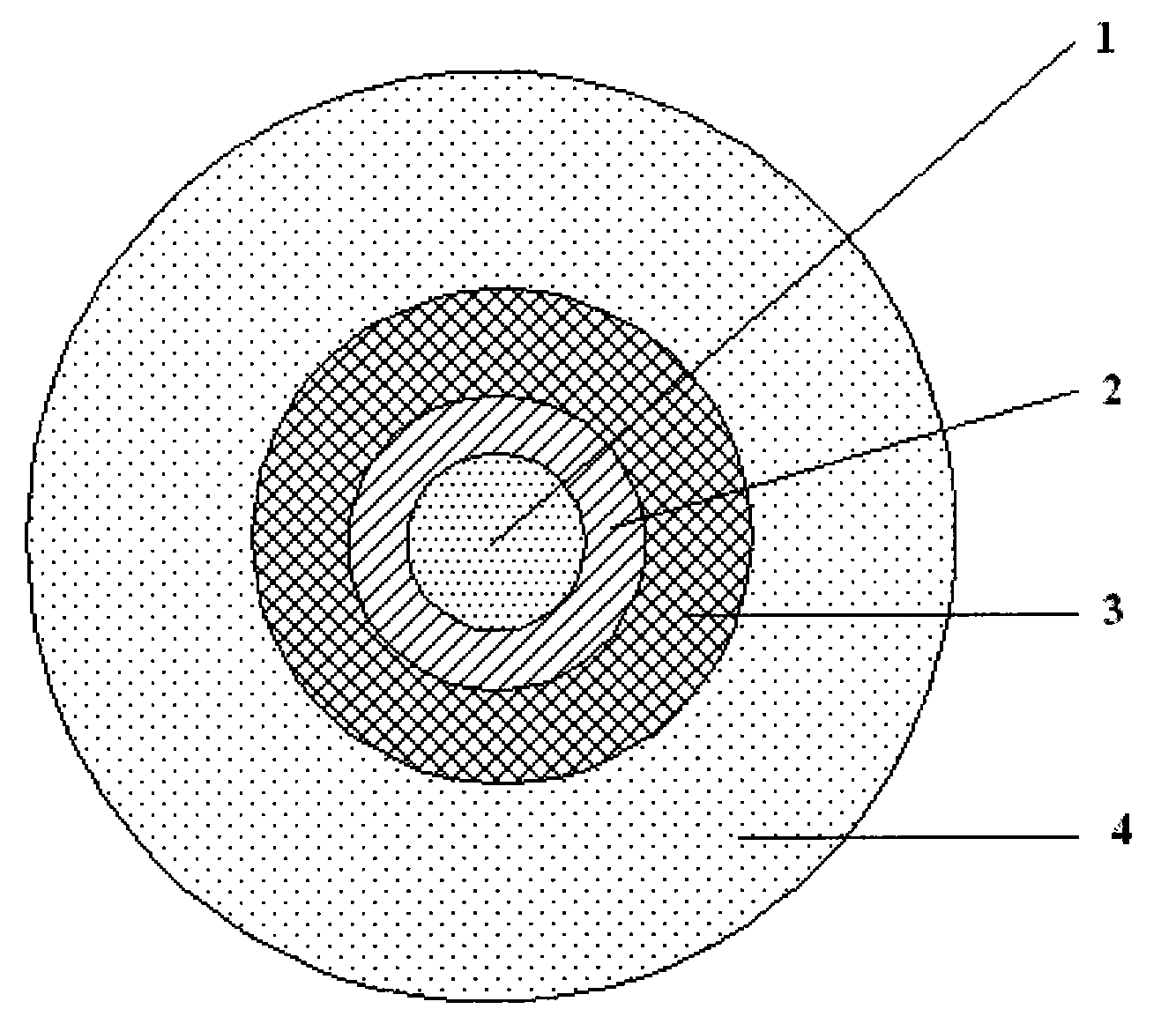

[0022] It includes a glass bare optical fiber 1, a buffer layer 2 and a transition layer 3 are sequentially coated on the outer periphery of the glass bare fiber, and an outer protective layer 4 is coated on the outside of the transition layer.

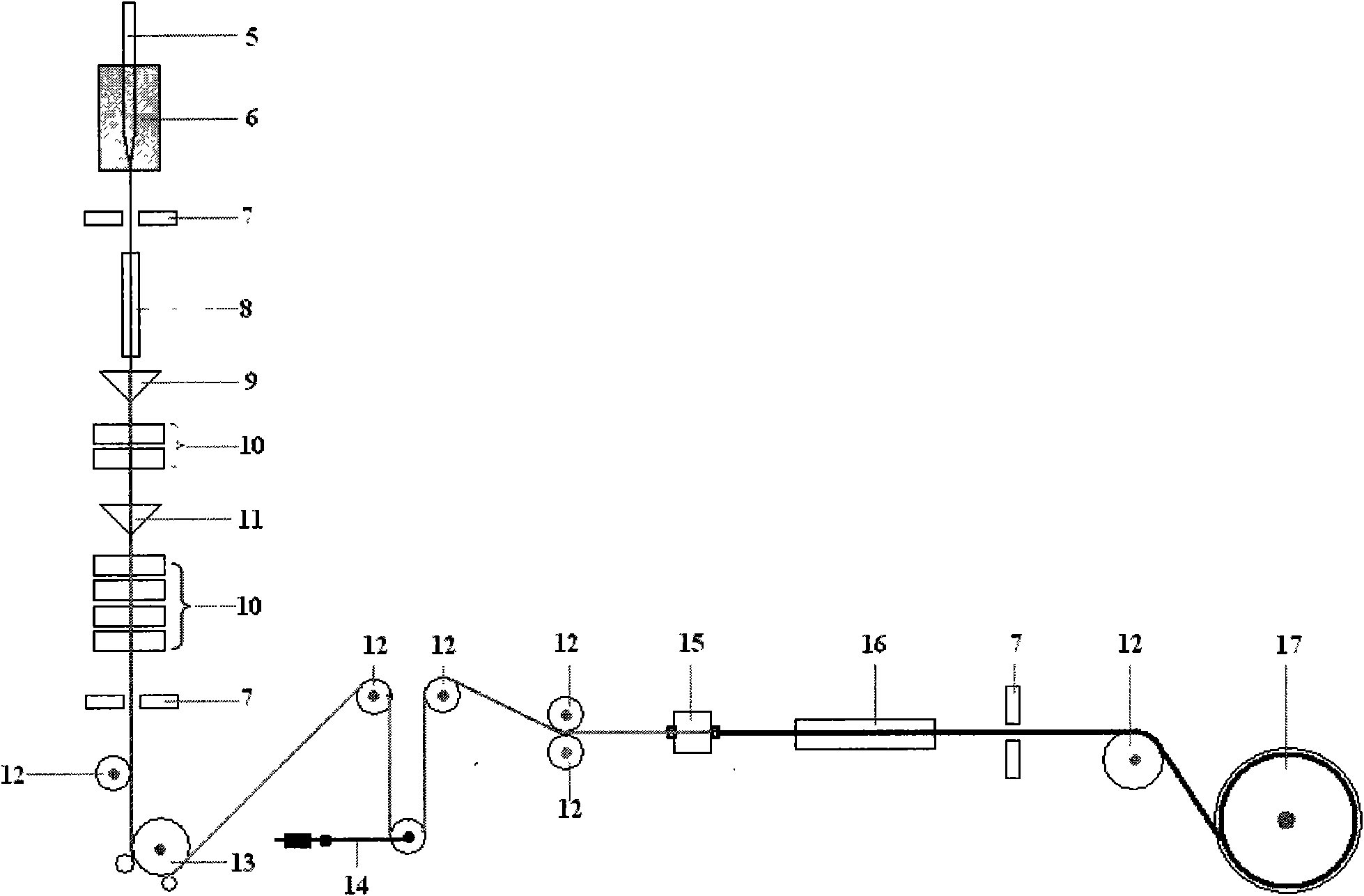

[0023] The manufacturing process of the optical fiber is as follows: put the optical fiber preform 5 into the drawing furnace 6, heat and pull out the optical fiber, after the optical fiber is cooled by the outer diameter measuring instrument 7 and the cooling pipe 8, it passes through two surface coating devices 9, 11 and The ultraviolet curing device 10 is used for coating and curing of the buffer layer and the coating and curing of the transition layer. After the optical fiber coated with the buffer layer and the transition layer is drawn out, it passes through the outer diameter measuring instrumen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com