New method and device for arbitrary beam shaping

A new method and beam technology, applied in optics, optical components, instruments, etc., can solve problems such as difficulties in the application of strong laser systems, low light energy utilization efficiency, and small uniformly irradiated areas, and achieve the effect of simplifying the composition of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

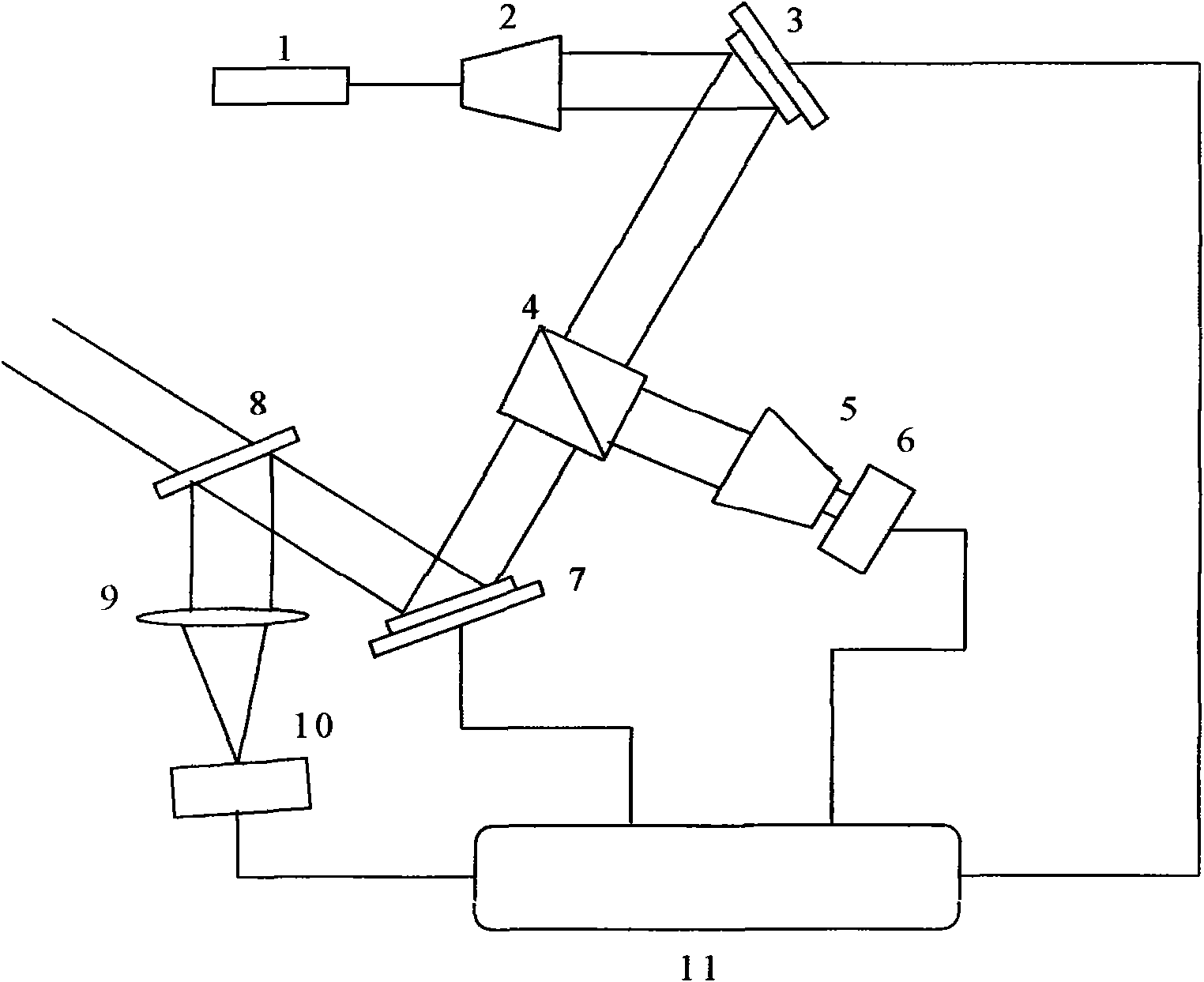

[0043] Such as figure 1 As shown, the whole system consists of a laser to be shaped 1, a beam expander 2, a first deformable mirror 3, a beam splitter 4, a beam shrinker 5, an image sensor 6, a second deformable mirror 7, a beam splitter 8, a focusing A lens 9, an image sensor 10, and an algorithm controller 11 are composed. The laser 1 is located before the beam expander 2, the first deformable mirror 3 is located behind the beam expander 2, the beam splitter 4 is located between the first deformable mirror 3 and the second deformable mirror 7, and the beam reducer 5 is located Between the beam mirror 4 and the image sensor 6, the focusing lens 9 is located between the beam splitter mirror 8 and the image sensor 10, the algorithm controller 11 communicates with the image sensor 6, the image sensor 10, the first deformable mirror 3, and the second deformable mirror 7 connections.

[0044] 1. First build the figure 1 In the platform shown, the laser light emitted by the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com