Aqueous coating resin composition

A resin composition, water-based resin technology, applied in the direction of coating, latex paint, etc., to achieve the effect of excellent pollution resistance, weather resistance and pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

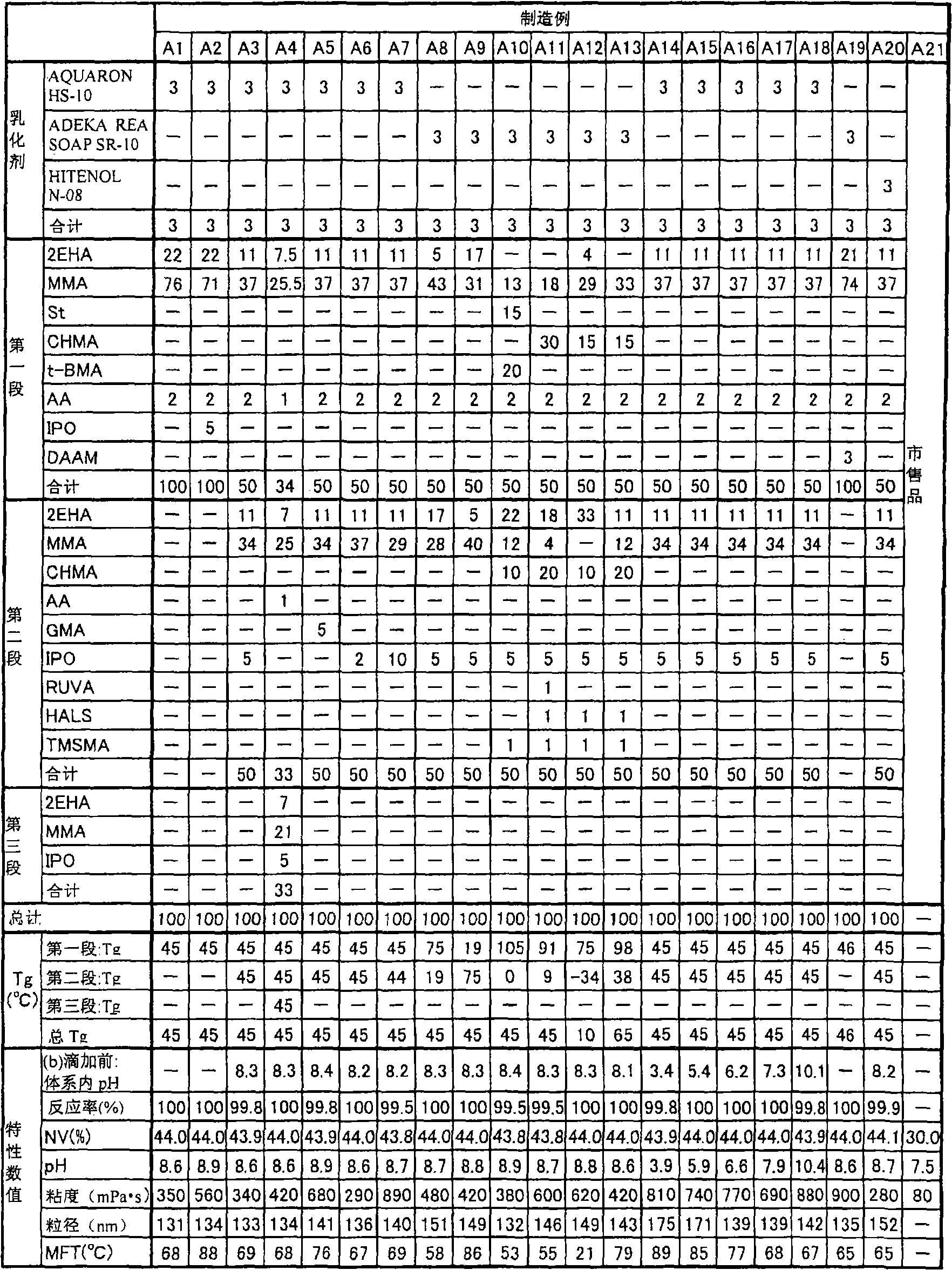

manufacture example A1

[0186] 432 parts of deionized water were added to a flask equipped with a dropping funnel, a stirrer, a nitrogen gas introduction tube, a thermometer, and a reflux condenser. In a dropping funnel, prepare 145 parts of deionized water, 60 parts of a 25% aqueous solution of an emulsifier (for example: AQUARON-HS-10 / manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), 110 parts of 2-ethylhexyl acrylate, 380 parts Add 70.5 parts of the pre-emulsion for dripping composed of methyl methacrylate and 10 parts of acrylic acid, which is equivalent to 10% of the total amount of all polymerizable monomer components, to the flask, and slowly blow nitrogen into it while raising the temperature. To 80°C, 30 parts of a 5% aqueous solution of ammonium persulfate was added to initiate polymerization. Thereafter, the remaining pre-emulsion for dropping was uniformly added dropwise over 240 minutes. After the dropwise addition, keep at the same temperature for 180 minutes, then add 7 parts...

manufacture example A2

[0190] Except having superposed|polymerized using the emulsifier and monomer component shown in following Table 1, it carried out similarly to manufacture example A1, and obtained the (meth)acryloyl emulsion (A2). Various physical properties were evaluated in the same manner as in Production Example A1. The evaluation results are listed in Table 1.

manufacture example A3

[0192] 432 parts of deionized water were added to a flask equipped with a dropping funnel, a stirrer, a nitrogen gas introduction tube, a thermometer, and a reflux condenser. In the dropping funnel, prepare 25% aqueous solution of 72.5 parts of deionized water, 30 parts of emulsifier (for example: AQUARON HS-10 / manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), 55 parts of 2-ethylhexyl acrylate, 185 parts of methyl The first stage of the pre-emulsion composed of methyl acrylate and 10 parts of acrylic acid, 70.5 parts of which is equivalent to 10% of the total amount of all polymerizable monomer components are added to the flask, nitrogen gas is slowly blown in, and the temperature is raised at the same time To 80°C, 30 parts of a 5% aqueous solution of ammonium persulfate was added to initiate polymerization. Thereafter, the remaining first stage pre-emulsion was evenly added dropwise over 120 minutes. After the dropwise addition, the same temperature was maintained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com