Forage liquid phytase preparation

A liquid phytase and phytase proenzyme technology, which is applied in the field of liquid phytase preparations for feed, can solve the problems of poor enzyme activity storage stability, reduced activity, and easy to be affected by physical and chemical factors, etc. Effects on storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

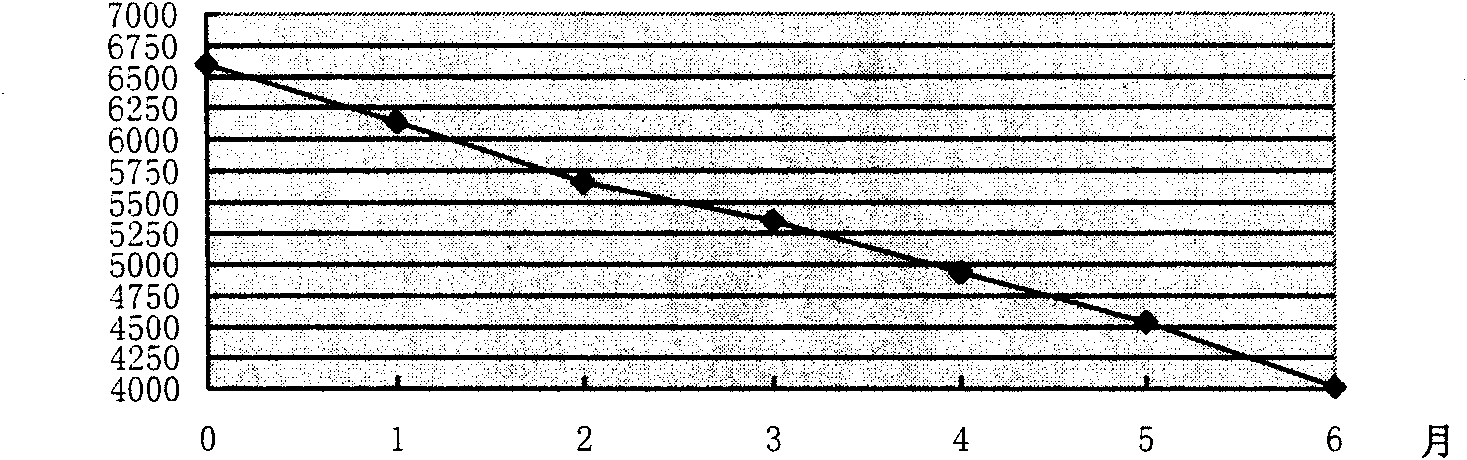

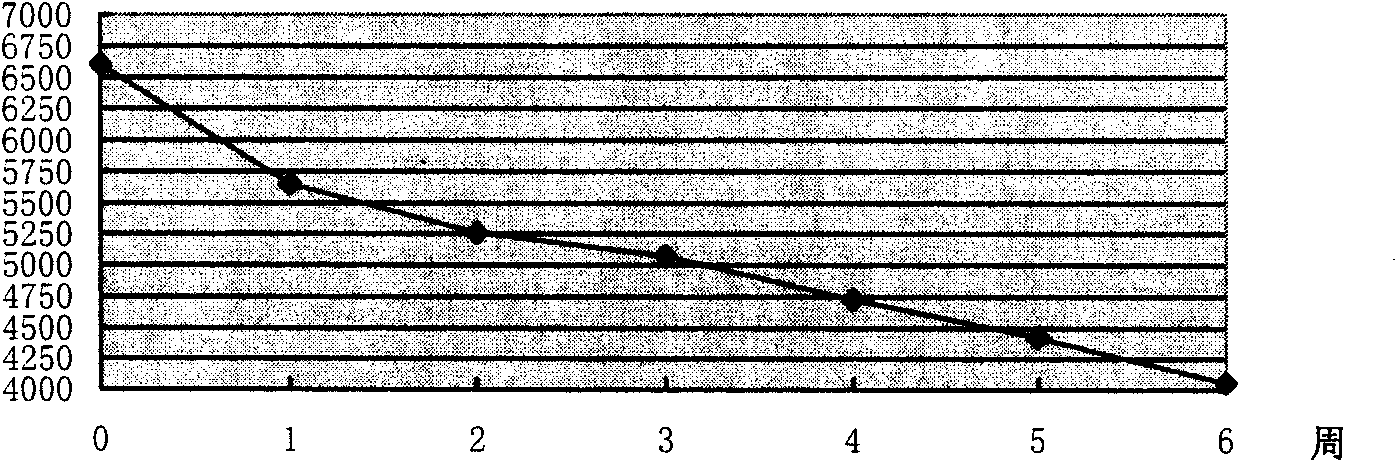

[0028] Weigh 600-30kg of polyethylene glycol, 50kg of trehalose, and 0.5kg of sodium benzoate, while stirring, slowly add to 600kg of distilled water, control the temperature below 40°C, and after all the solids are dissolved, add 300kg of plant with an enzyme activity of 23270u / g Stir the phytase solution evenly, then adjust the pH to 4.5 with 20kg of 0.5M HCl to obtain 1000.5kg of phytase solution with an enzyme activity of 6981u / g. Such as image 3 , Figure 4 Shown are the stability analysis of the liquid phytase preparation prepared according to the formula of this example stored at room temperature for 6 months and at 40° C. for 6 weeks. After analysis and calculation, the enzyme activity retention rate of this product is 90% when stored at room temperature for 6 months, and the enzyme activity retention rate is 83% when stored at a constant temperature of 40°C for 6 weeks.

Embodiment 2

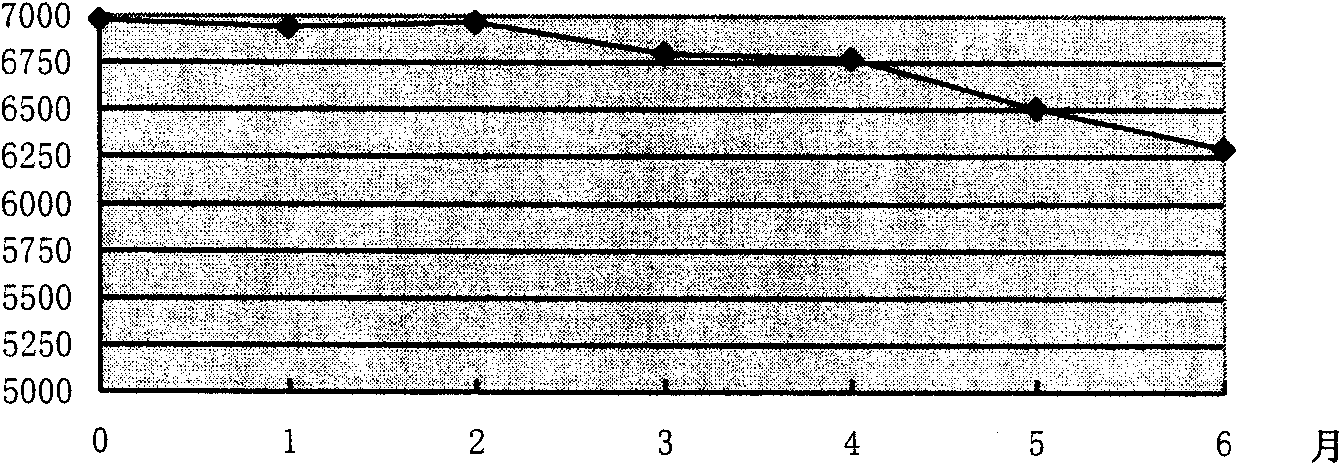

[0030] Weigh 600-40kg of polyethylene glycol, 75kg of trehalose, and 1kg of sodium benzoate, while stirring, slowly add to 600kg of distilled water, control the temperature below 40°C, after all the solids are dissolved, add 260kg of plant with an enzyme activity of 25880u / g Stir the phytase solution evenly, then adjust the pH to 5.0 with 4kg of 0.5M NaOH and 20kg of 0.5M HCl to obtain 1000kg of phytase solution with an enzyme activity of 6729u / g. Such as Figure 5 , Figure 6 Shown are the stability analysis of the liquid phytase preparation prepared according to the formula of this example stored at room temperature for 6 months and at 40° C. for 6 weeks. After analysis and calculation, the enzyme activity retention rate of this product is 80% when stored at room temperature for 6 months, and the enzyme activity retention rate is 82.8% when stored at a constant temperature of 40°C for 6 weeks.

Embodiment 3

[0032] Weigh 600-50kg of polyethylene glycol, 100kg of trehalose, and 1.5kg of sodium benzoate, while stirring, slowly add to 600kg of distilled water, control the temperature to less than 40°C, and after all the solids are dissolved, add 250kg of the enzyme activity of 27836u / g Stir the phytase solution evenly, then adjust the pH to 5.5 with 0.5kg of 0.5M NaOH to obtain 1002kg of phytase solution with an enzyme activity of 6959u / g. Such as Figure 7 , Figure 8 Shown are the stability analysis of the liquid phytase preparation prepared according to the formula of this example stored at room temperature for 6 months and at 40° C. for 6 weeks. According to analysis and calculation, the enzyme activity retention rate of this product stored at room temperature for 6 months is 84%, and the enzyme activity retention rate of 6 weeks at 40°C is 82.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com