Preparation method and product of biomedical porous implantation body

A technology for biomedical and implants, which is applied in the field of preparation of porous biomedical implants, can solve the problems of decreased mechanical properties of implants, unfavorable formation of mineralized bone, etc., and achieve controllable porosity and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

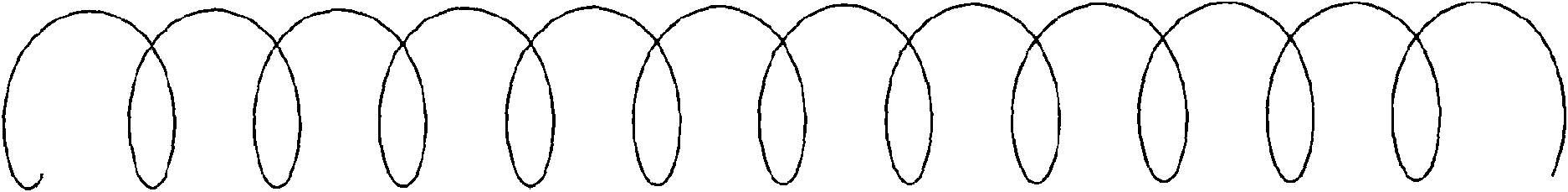

[0040] Take a nickel-titanium alloy wire with a diameter of 0.1mm and a mass ratio of titanium to nickel of 40:60, wind it into a helical wire with a pitch of 1mm and a diameter of 1mm to form a basic unit, and lay the basic units vertically to form a single-layer porous The net-like sheet is tightly curled to form a net-like structure, and then the net-like structure is put into a mold and pressed to become a rough implant body. In this embodiment, the pressure applied during pressing is 20 MPa, and the pressing time is 10 minutes.

[0041] At 20°C, the rough implant body was ultrasonically cleaned with a mixed solvent of acetone and absolute ethanol with a mixing volume ratio of 1:1 for 20 minutes, and then treated with a mixed acid for 20 minutes. The mixed acid volume ratio was HF:HNO 3 :H 2 O=1:2:3, followed by washing with deionized water. This is a routine surface cleaning step to remove impurities from the surface of the alloy wire.

[0042] Then the rough implant b...

example 2

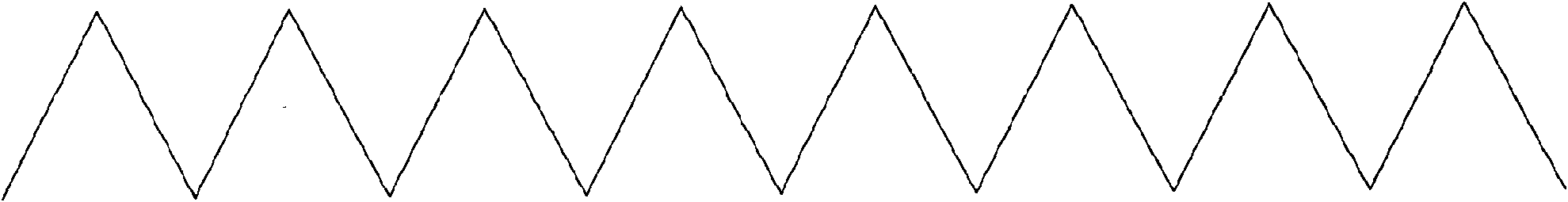

[0046] Take a nickel-titanium alloy wire with a diameter of 0.1 mm and a mass ratio of titanium to nickel of 45:55, fold it into a sawtooth structure with a tooth pitch of 1 mm and a tooth height of 1 mm to form a basic unit, and lay the basic units vertically to form a single-layer porous structure. The net-like sheet is tightly curled to form a net-like structure, and the net-like structure is put into a mold, and the rough blank of the implant is taken out after compression molding. In this embodiment, the pressure applied during pressing is 25 MPa, and the pressing time is 5 minutes.

[0047] At 35°C, the rough implant body was ultrasonically cleaned with a mixed solvent of acetone and absolute ethanol with a mixing volume ratio of 1:1 for 22 minutes, and then treated with a mixed acid for 40 minutes. The mixed acid volume ratio was HF:HNO 3 :H 2 O=1:2:3, followed by washing with deionized water.

[0048] Then the rough implant body is vacuumed at 1200°C (vacuum degree i...

example 3

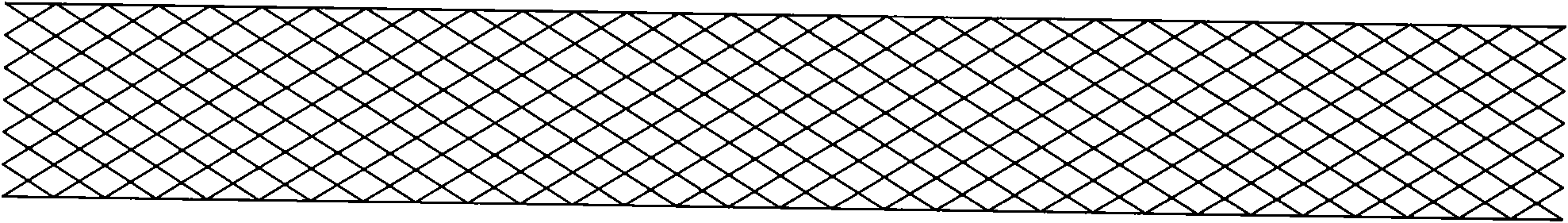

[0050] Take a nickel-titanium alloy wire with a diameter of 0.1mm and a mass ratio of titanium to nickel of 45:55, weave it into a mesh tube with a diameter of 1mm to form a basic unit, and arrange the basic units vertically to form a single-layer porous mesh sheet, and then Tightly curl the single-layer porous mesh sheet to form a mesh structure, put the mesh structure into a mold, and take out the rough blank of the implant after compression molding. The pressure applied in this embodiment is 30 MPa, and the pressing time is 8 minutes.

[0051] At 50°C, the rough implant body was ultrasonically cleaned with a mixed solvent of acetone and absolute ethanol with a mixing volume ratio of 1:1 for 27 minutes, and then treated with a mixed acid for 50 minutes. The mixed acid volume ratio was HF:HNO 3 :H 2 O=1:2:3, followed by washing with deionized water.

[0052] Then the rough implant body is vacuumed at 1250°C (vacuum degree is 1.0×10 -3 Pa) under sintering for 2 hours, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com