Method for preparing small-size meso-porous hollow carbon sphere

A hollow carbon sphere, small-sized technology, applied in chemical instruments and methods, medical preparations of non-active ingredients, pharmaceutical formulations, etc., can solve the problem of inability to control the size of mesoporous hollow carbon spheres, complex synthesis process steps, time-consuming and High cost and other issues, to achieve the effect of controllable size, large pore volume, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]First prepare aluminum-doped mesoporous silica core-shell spheres with a size of 260-280nm: 6.28mL ammonia water (14% by mass), 74mL absolute ethanol and 10mL deionized water, add 6mL orthosilicic acid at 30°C Stir for 1 h after ethyl ester; then add 5 mL of tetraethyl orthosilicate and 2 mL of octadecyltrimethoxysilane, and 1 mL of aluminum sulfate aqueous solution with a concentration of 0.45 mol / L to continue the reaction for 1 h; centrifuge the resultant, wash and After drying, calcining at 550° C. for 6 h to remove the template, thereby preparing aluminum-doped mesoporous silica core-shell spheres. Take 0.5g of the above powder and put it into a small beaker, drop 0.6mL of furfuryl alcohol into the powder at a rate of 0.3mL / min to make the furfuryl alcohol fully wet the powder; then put the small beaker into a vacuum oven at 60°C for heating After 3h, start vacuuming and maintain the vacuum state for 10h; put the obtained powder into the atmosphere furnace, raise it...

Embodiment 2

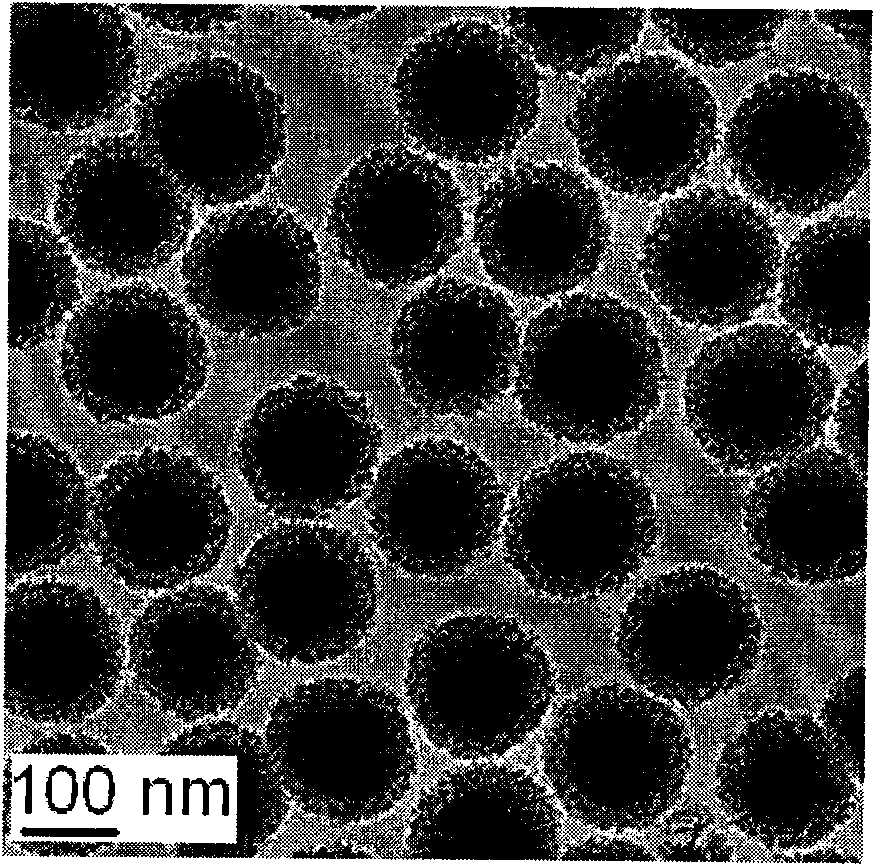

[0052] First prepare aluminum-doped mesoporous silica core-shell spheres with a size of 160-180nm: 3.14mL ammonia water (30% by mass), 74mL absolute ethanol and 10mL deionized water, add 6mL orthosilicic acid at 30°C Stir for 1 h after ethyl ester; then add 5 mL of tetraethyl orthosilicate and 2 mL of octadecyltrimethoxysilane, and 1 mL of aluminum sulfate aqueous solution with a concentration of 0.45 mol / L to continue the reaction for 1 h; centrifuge the resultant, wash and After drying, calcining at 550° C. for 6 h to remove the template, thereby preparing aluminum-doped mesoporous silica core-shell spheres. Intuitive description see figure 1 . Take 0.5g of the above powder and put it into a small beaker, drop 0.6mL of furfuryl alcohol into the powder at a rate of 0.3mL / min to make the furfuryl alcohol fully wet the powder; then put the small beaker into a vacuum oven at 60°C for heating After 3h, start vacuuming and maintain the vacuum state for 10h; put the obtained powd...

Embodiment 3

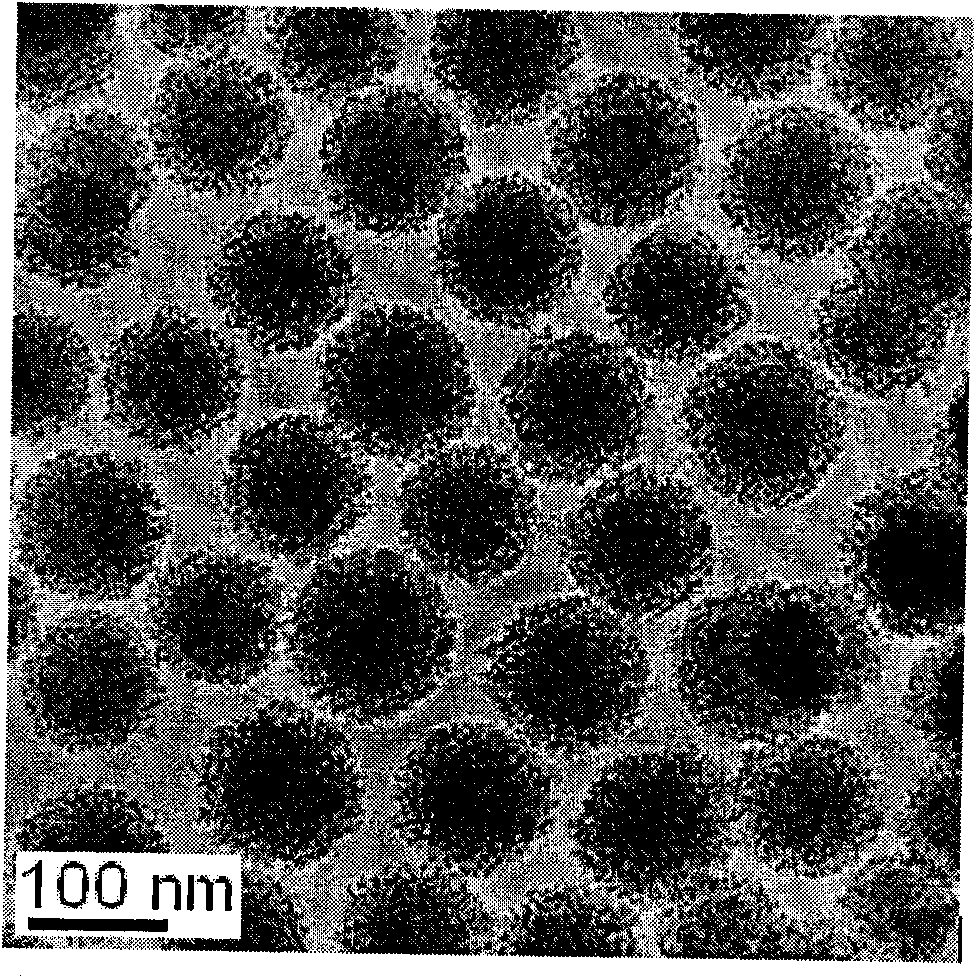

[0054] According to the process described (same as Example 1), first prepare aluminum-doped mesoporous silica core-shell spheres with a size of 80-100 nm: 3.14 mL of ammonia water (22% by mass), 148 mL of absolute ethanol and 20 mL of dehydrated Add 6 mL of tetraethyl orthosilicate to ionic water at 30°C and stir for 1 hour; then add 5 mL of tetraethyl orthosilicate and 2 mL of octadecyltrimethoxysilane, and 1 mL of aqueous aluminum sulfate solution with a concentration of 0.45 mol / L The reaction was continued for 1 hour; the resultant was centrifuged, washed and dried, and calcined at 550° C. for 6 hours to remove the template, thereby preparing aluminum-doped mesoporous silica core-shell spheres. Intuitive shape attached image 3 . Take 0.5g of the above powder and put it into a small beaker, drop 0.6mL of furfuryl alcohol into the powder at a rate of 0.3mL / min to make the furfuryl alcohol fully wet the powder; then put the small beaker into a vacuum oven at 60°C for heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com