Method for regenerating and maintaining activity of ionic liquid catalyst and method for producing alkylate

A technology of alkylation oil and catalytic activity, which is applied in the field of petrochemical industry, can solve the problems of unfavorable industrial production development, frequent replacement and regeneration, etc., and achieve the effect of easy operation, prolonging service life and maintaining catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

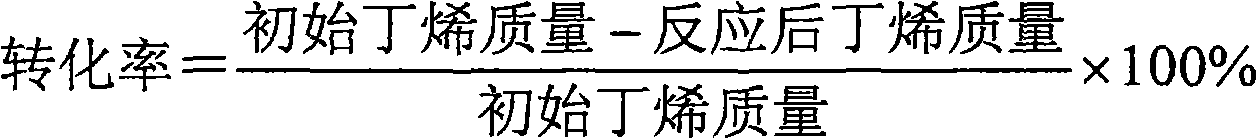

[0040] Change the cation from Et 3 Provided by NHCl, the anion is provided by AlCl 3 The acidic ionic liquid provided by CuCl is used as a catalyst to catalyze the isobutane alkylation reaction on a continuous device. The amount of ionic liquid added is 200g, the reaction pressure is 0.5MPa, the reaction temperature is 25°C, and the raw materials are isobutane and 2- A mixture of butenes, the molar ratio of alkene to 20:1, the alkylation product obtained by catalytic alkylation reaction with a fresh catalyst was collected, and its composition was analyzed. The results are shown in Table 1.

[0041] As can be seen from Table 1, when the amount of raw material treated by per gram of ionic liquid catalyst reaches 50 grams, the catalyst activity obviously declines; The catalyst was completely deactivated, and a total of 1120 g of alkylated oil products were obtained.

[0042] Table 1 Continuous evaluation of fresh ionic liquid catalytic alkylation

[0043]

[0044] Such as ...

Embodiment 2

[0052] The cation is provided by [bmim]Cl (butylmethylimidazolium chloride), and the anion is provided by AlBr 3 and CuSO 4 The acidic ionic liquid provided is used as a catalyst to catalyze the alkylation reaction of isobutane on a continuous device. The amount of ionic liquid added is 200g, the reaction pressure is 0.5MPa, the reaction temperature is 20°C, and the raw materials are isobutane and 2-butene , isobutene and 1-butene, the molar ratio of alkene is 40:1, collect the alkylation product catalyzed by fresh catalyst, analyze its composition, the results are shown in Table 4.

[0053] It can be seen that when the amount of raw material treated by each gram of ionic liquid catalyst reaches 100 grams, the catalyst activity significantly decreases, and when the amount of raw material treated by each gram of ionic liquid catalyst reaches 110 grams, the catalyst is completely deactivated, and at this time a total of alkylated oil products are obtained 1021g.

[0054] Table...

Embodiment 3

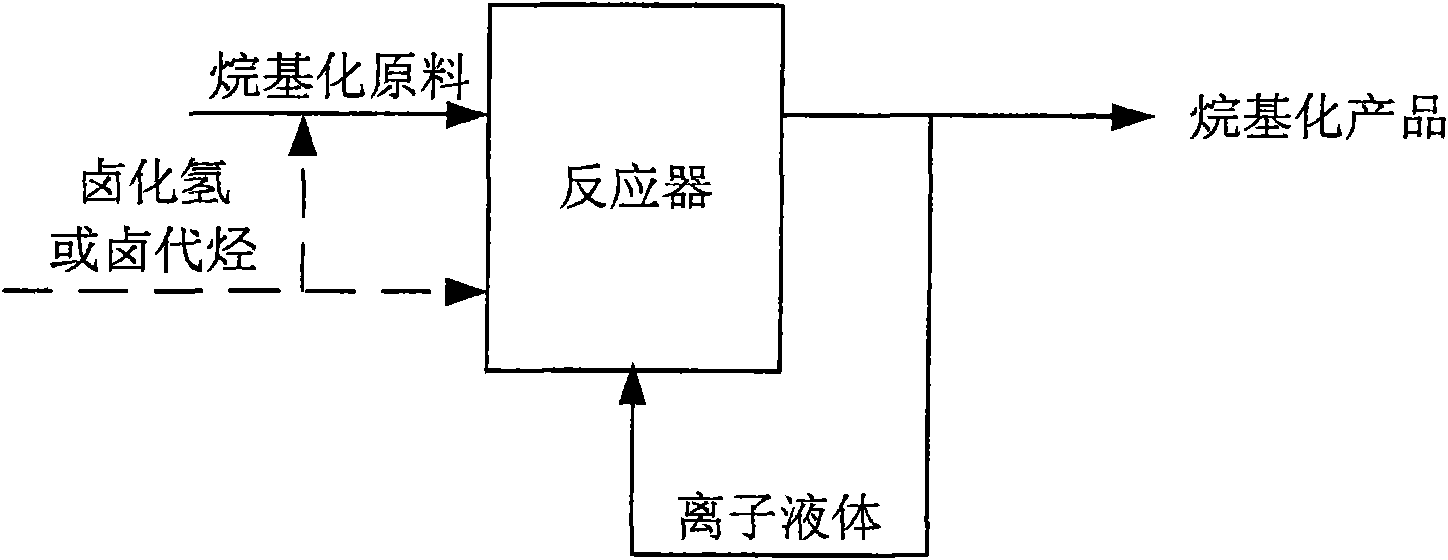

[0066] For the reaction process, see figure 1 , the cation is provided by [bmim]Cl and the anion by AlCl 3 The acidic ionic liquid provided is used as a catalyst to catalyze the alkylation reaction of isobutane on a continuous device. The amount of ionic liquid added is 30kg, the reaction pressure is 0.5MPa, the reaction temperature is 30°C, and the reaction raw materials are isobutane, 2-butane The mixture of alkenes, isobutenes and 1-butenes, the molar ratio of alkanes to alkenes is 10:1, the feeding rate of raw materials is 12kg / h, the yield of alkylated oil is 2.4kg / h, and the reaction is carried out continuously at 2g / h Pass hydrogen chloride into the vessel (or pass into the reactor together after being mixed with the reaction raw materials), collect the alkylation product, analyze its composition, and the results are shown in Table 7.

[0067] It can be seen from Table 7 that when the amount of raw material treated per kilogram of ionic liquid catalyst reaches 1000 kil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com