Resin-poured reel iron core transformer

A resin casting and winding iron core technology is applied in the field of winding iron core transformers, which can solve the problems of easy accumulation of dust and affect insulation performance, and achieve the effects of reducing noise, enhancing short-circuit impact resistance and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The accompanying drawings disclose the basic structure of the present invention without limitation, and the present invention will be further described below in conjunction with the embodiments.

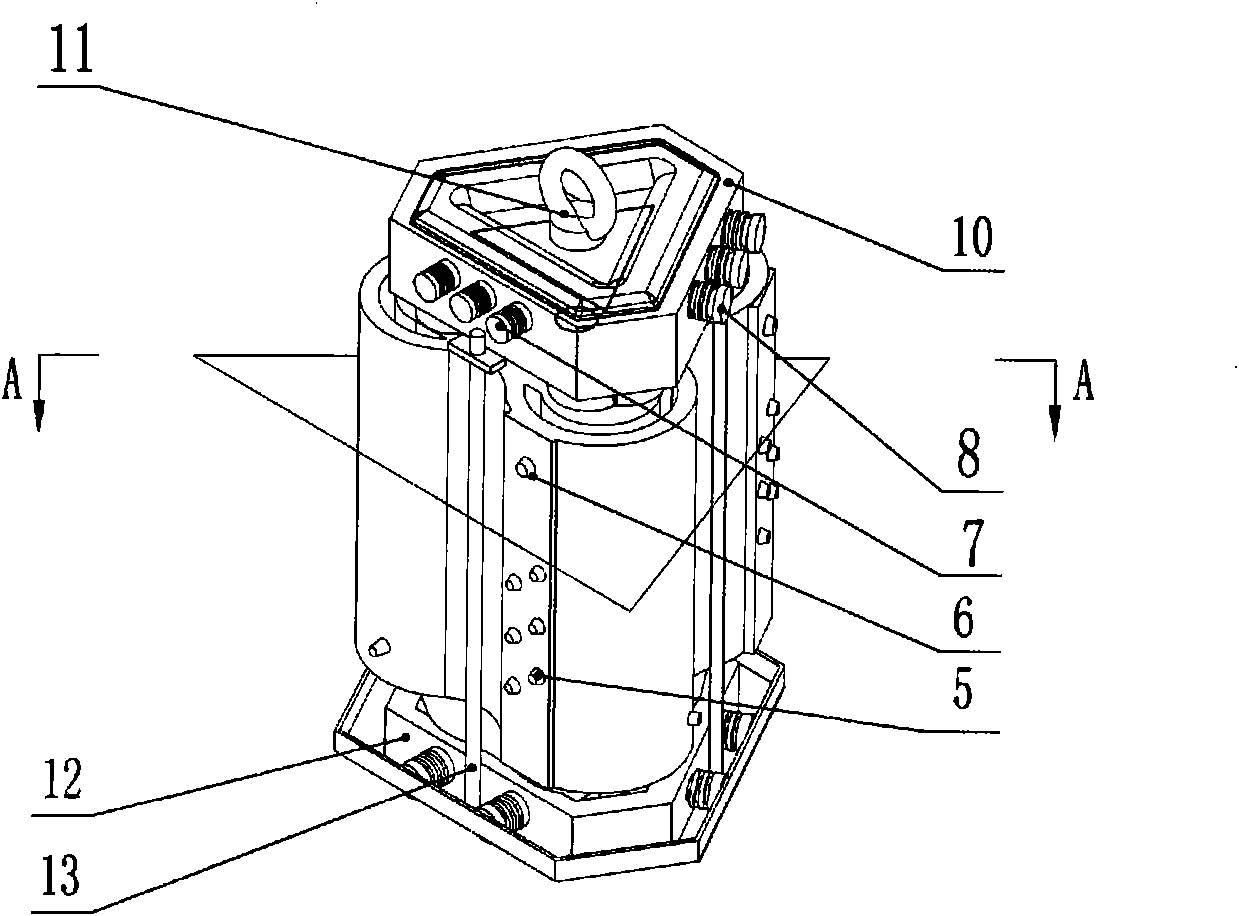

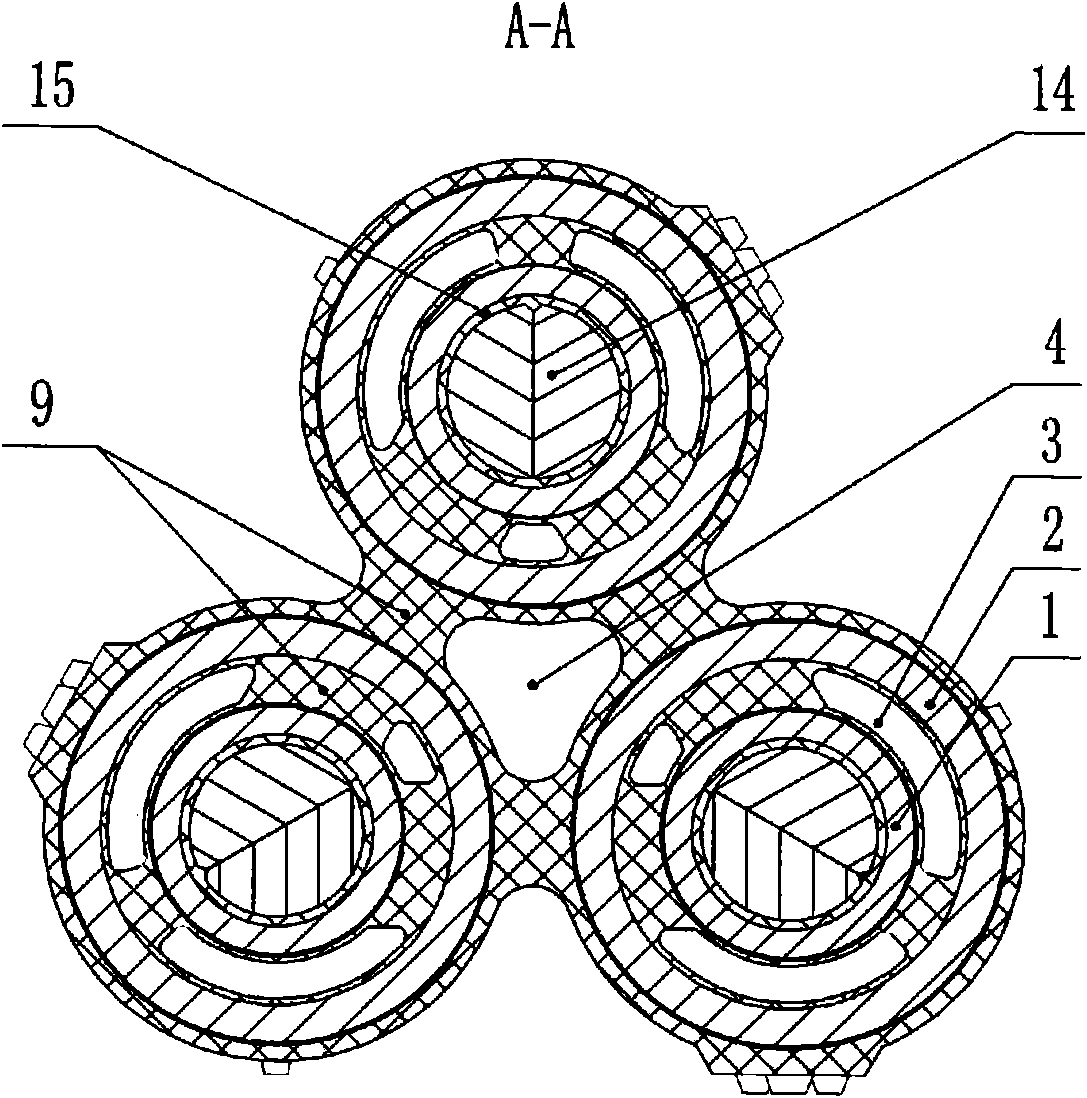

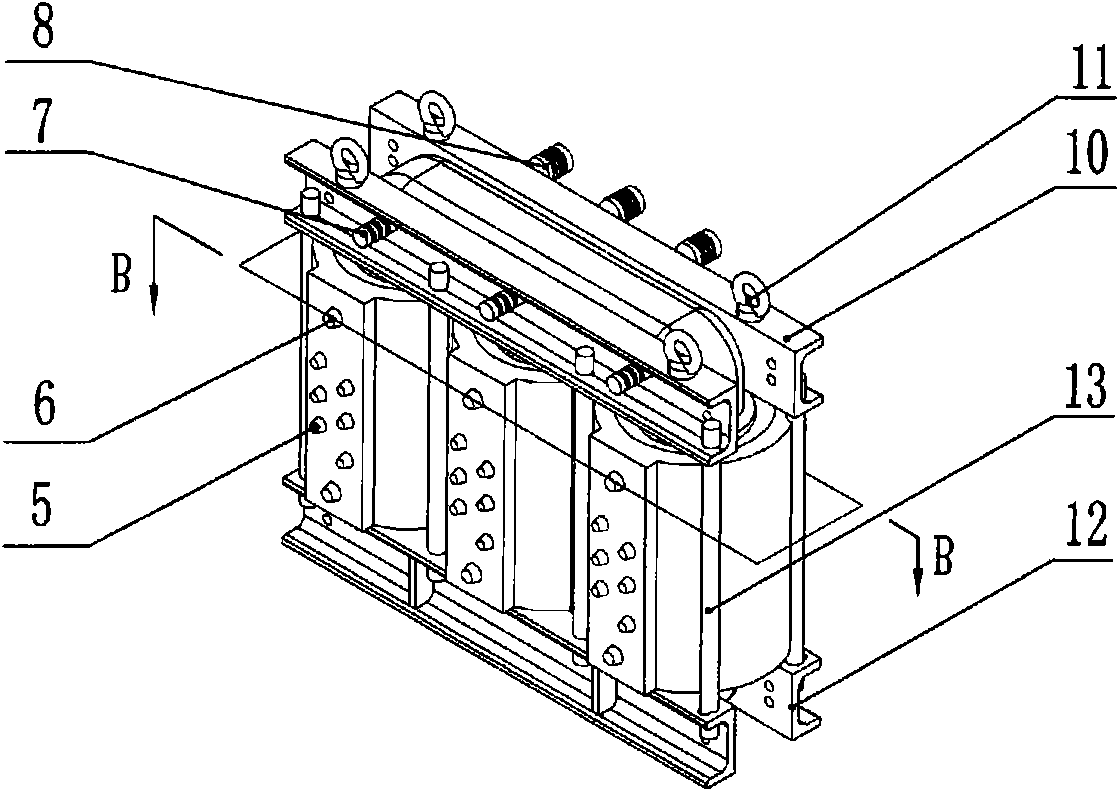

[0020] Depend on figure 1 with figure 2 It can be seen that the iron core in this embodiment is a three-dimensional triangular wound iron core 14 formed by combining three independent single-frame wound iron cores, and a coil bobbin 15 is arranged on the same iron core column of the three-dimensional triangular wound iron core, and the coil bobbin 15 The low-voltage wire package 1 and the high-voltage wire package 2 are wound on top, and the low-voltage wire package 1 and the high-voltage wire package 2 are casted by epoxy resin 9 to form a whole. There is also a central airway 4 in the center of the wire pack. The upper part of the triangular coiled iron core is provided with an upper end clamp 10, the lower part is provided with a lower end clamp 12, and the upper end cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com