Anion exchange membranes

An anion exchange membrane, ion conductivity technology, applied in the field of anion exchange membrane production, can solve the problems of poor stability of AEM, AEM unsuitable for alkaline fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

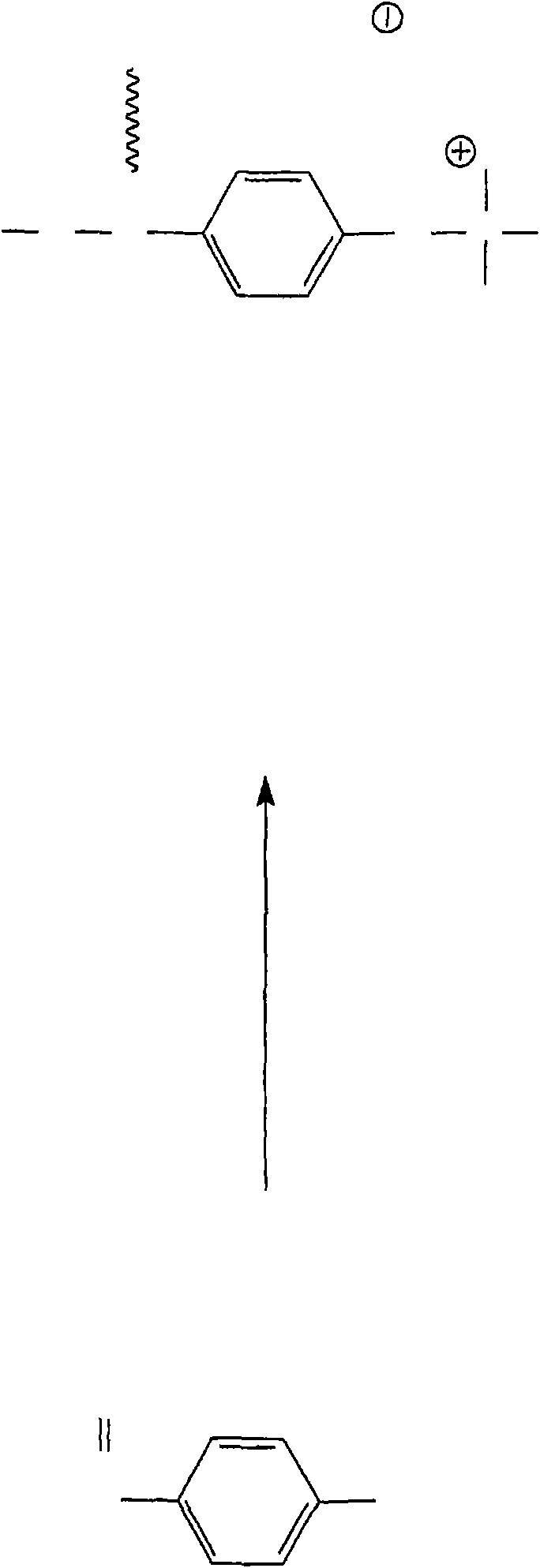

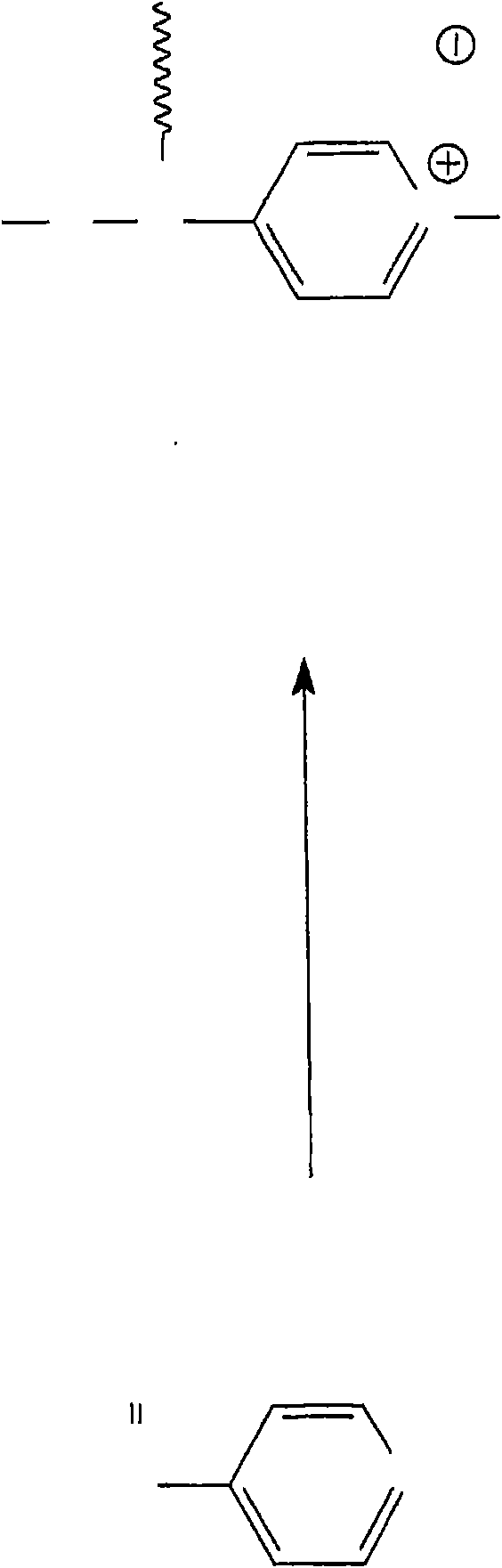

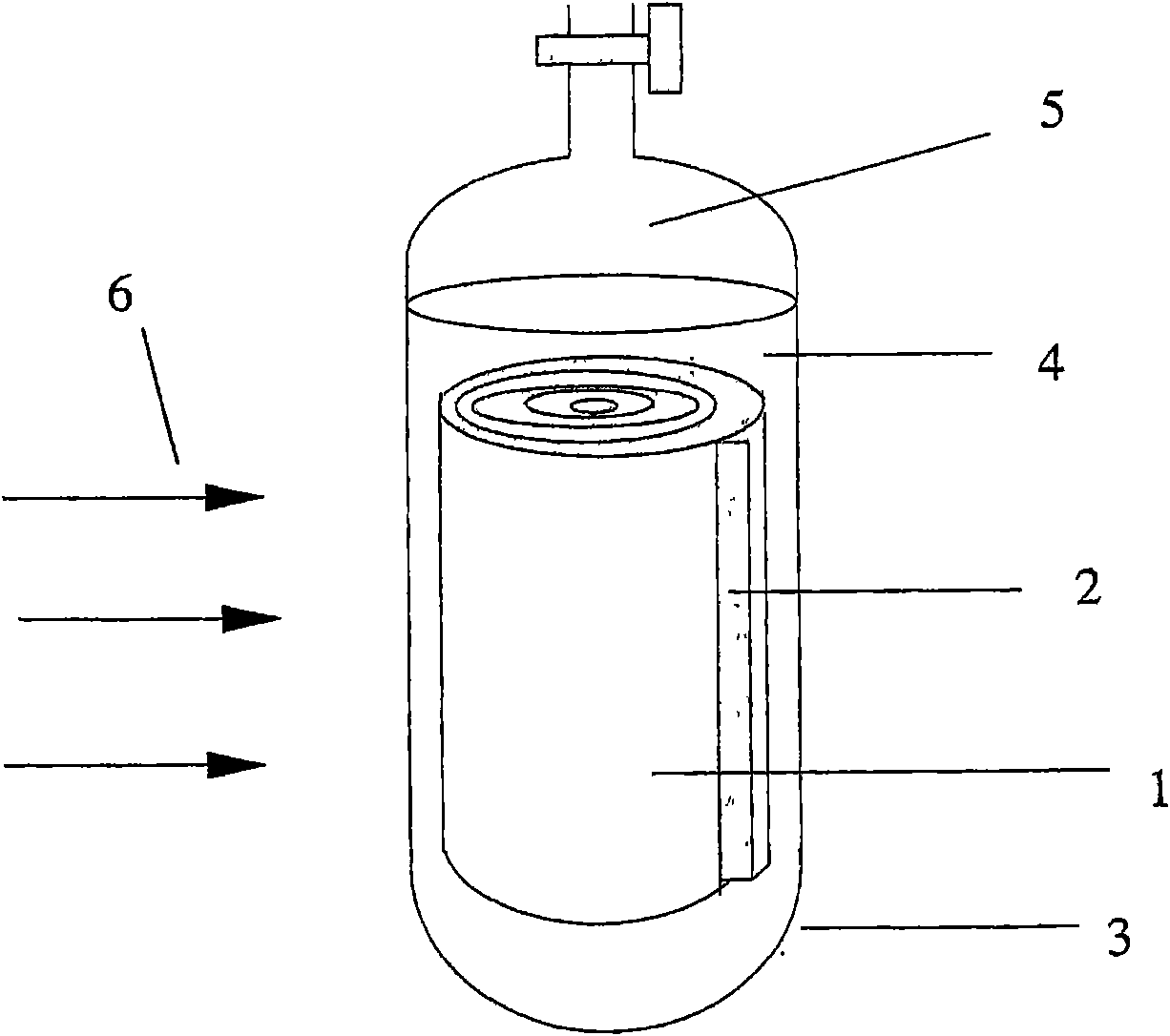

Method used

Image

Examples

Embodiment 1

[0044] This example discloses the mutual grafting reaction with vinylbenzyl chloride (VBC) as monomer. The base polymer films used for the films were 50 μm low density polyethylene (LDPE) and 40 μm high density polyethylene (HDPE). Other base polymers, such as ethylene tetrafluoroethylene (ETFE), have also been used, but the resulting membranes did not perform well in property tests.

[0045] Experiments were performed under two conditions: keeping the total dose constant while varying the dose rate (grafting time), and keeping the dose rate constant but varying the total dose.

[0046] The optimal total radiation dose for interfilm was found to be 1 Mrad at low dose rates. Higher total doses produced undesired parasitic reactions (homopolymerization) and resulted in lower DOG. DOG was found to increase at lower dose rates.

[0047] Table 1 demonstrates the effect of diluent composition on the resulting DOGs. It can be seen that DOG is improved by adding methanol.

[0048...

Embodiment 2

[0059] This example discloses the mutual grafting reaction with vinylpyridine (VPy) as monomer. The polymer films used were again 50 μm mL LDPE and 40 μm HDPE.

[0060] Quaternization of the VPy-grafted membranes was carried out by heat treatment with 5M HCl or 2-CA.

[0061] The obtained DOG is 10%-60%. Although a high degree of grafting can be obtained using VPy as a monomer, the performance of the membrane suffers as soon as the DOG exceeds a certain level; DOG above 58% is too brittle to be used as a membrane.

[0062] The results are summarized in Table 4, showing that the VPy-grafted films with DOG > 29%, aminated with 5M HCl or 2-CA had lower surface resistivity.

[0063] Table 4: Properties of VPy-grafted copolymers

[0064]

[0065] This invention was made with US Government support Grant N00014-02-1-0225 awarded by the US Naval Research Institute. The US Government has certain rights in this invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com