Nano composite light absorption material and preparation method thereof

A light-absorbing material, nano-composite technology, applied in optics, photographic technology, instruments, etc., can solve the problems of large coating amount, high raw material cost, increased consumption of chemical liquid aging, performance degradation, etc., to reduce the amount and price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

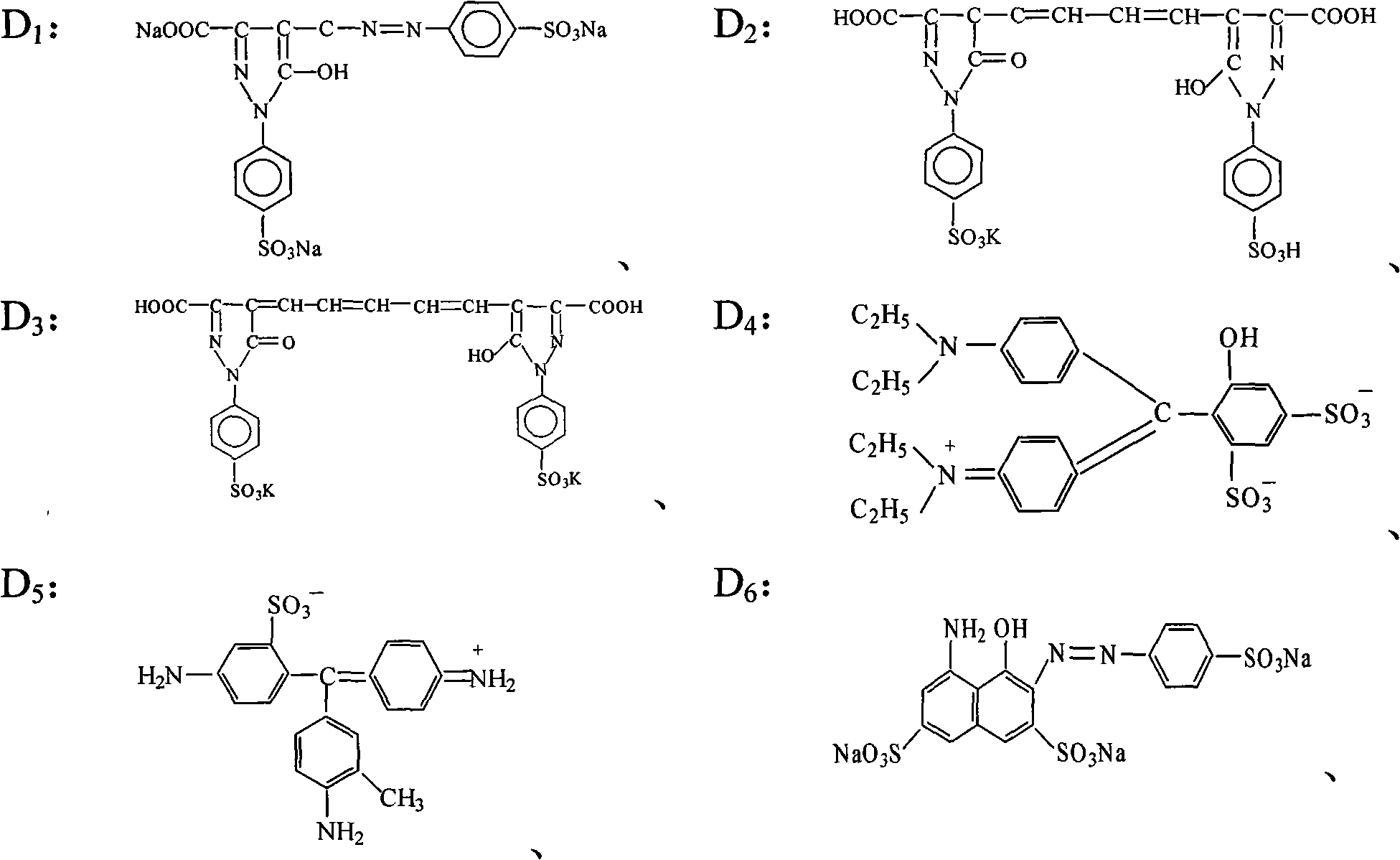

[0021] Adjust the temperature of the gelatin aqueous solution with a concentration of 60 g / L to 41 ° C, and add CaCO with a particle size of 50 to 70 nm 3 The particles are dispersed in an aqueous gelatin solution to give CaCO 3 A slurry with a particle weight concentration of 0.5%. Under stirring, add the silver nitrate solution that concentration is 1mol / L to slurry by 10% of slurry volume, then add sodium sulfite-hydroquinone solution by 48% of slurry volume (sodium sulfite concentration is 0.2mol / L, hydroquinone Concentration is 0.1mol / L), after reacting for 5min, add 0.01mol / L stabilizer S by 4% of the slurry volume 1 , add 0.1mol / L water-soluble dye D according to 12% of the slurry volume 3 , react for 5min. Cool down to 30°C and add 10% β-naphthalenesulfonic acid sodium formal aqueous solution as a sedimentation agent according to 4% of the slurry volume, settle, filter, wash, and the obtained precipitate is the nanocomposite of calcium carbonate / silver / dye light-ab...

Embodiment 2

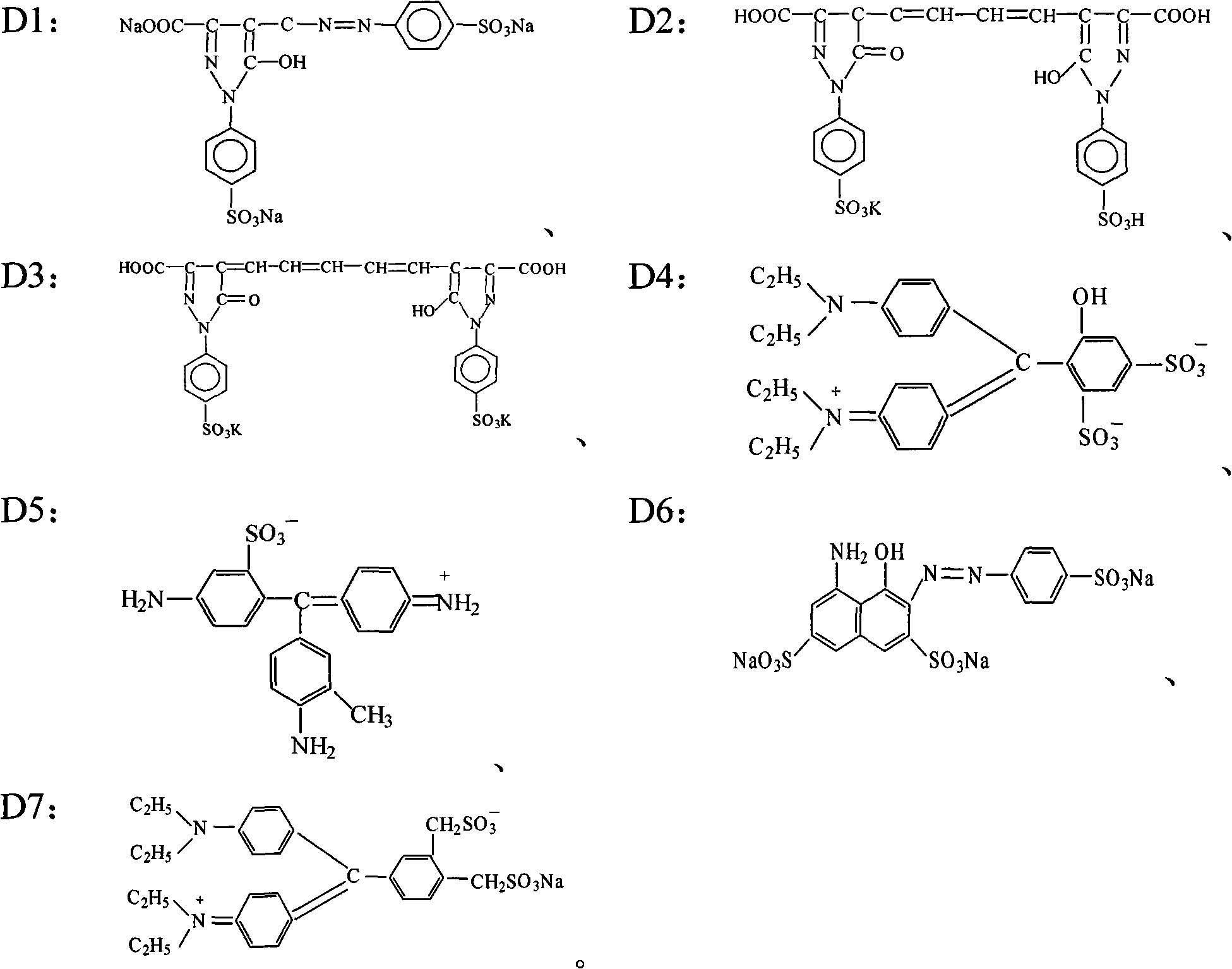

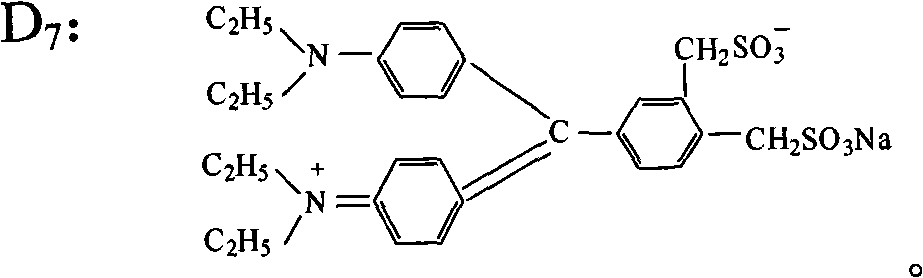

[0024] Adjust the temperature of the gelatin aqueous solution with a concentration of 40g / L to 38°C, and add Al with a particle size of 25-50 nm 2 o 3 The particles are dispersed in an aqueous gelatin solution to give Al 2 o 3 A slurry with a particle weight concentration of 0.2%. Under stirring, add 0.1mol / L water-soluble dye D to the slurry according to 10% of the volume of the slurry 1 、D 2 、D 3 mixed solution (D 1 、D 2 、D 3 The molar ratio is 1:1:1), reacted for 5min, then added 1mol / L silver nitrate solution by 15% of the slurry volume, then added sodium sulfite-hydroquinone solution by 65% of the slurry volume (sodium sulfite concentration is 0.2 mol / L, hydroquinone concentration is 0.1mol / L), reacted for 2min. Add 0.01mol / L stabilizer S according to 4.5% of the volume of the slurry 2 . Cool down to 30°C, add β-naphthalenesulfonic acid sodium formal aqueous solution with a concentration of 10% according to the weight of 2.5% of the slurry volume, settle, fil...

Embodiment 3

[0027] Adjust the temperature of the gelatin aqueous solution with a concentration of 100g / L to 50°C, and take TiO with a particle size of 50-70 nm in a molar ratio of 1:1. 2 Particles and BaSO with a particle size of 60-80 nanometers 4 The particles are dispersed in an aqueous gelatin solution to obtain a slurry with a particle mass concentration of 2%. Under stirring, add 2mol / L silver nitrate solution according to 50% of the slurry volume, after fully mixing, add sodium sulfite-hydroquinone solution according to 220% of the slurry volume (the concentration of sodium sulfite is 0.2mol / L, and the concentration of hydroquinone is 0.1 mol / L), reacted for 10min, then added 0.01mol / L stabilizer S according to 30% of the slurry volume 1 , Add 0.01mol / L water-soluble dye D according to 3.5% of the volume of the slurry 3 , react for 5min. Cool down to 35°C, add β-naphthalenesulfonic acid sodium formal solution with a mass concentration of 10% according to 8% of the volume of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com