Method for applying sludge heat drying and sludge digestion fermentation in combining way

A combined application, sludge technology, applied in the field of environmental protection and pollutant treatment, can solve the problems of lack of connection, high transportation cost, low porosity, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in combination with specific embodiments.

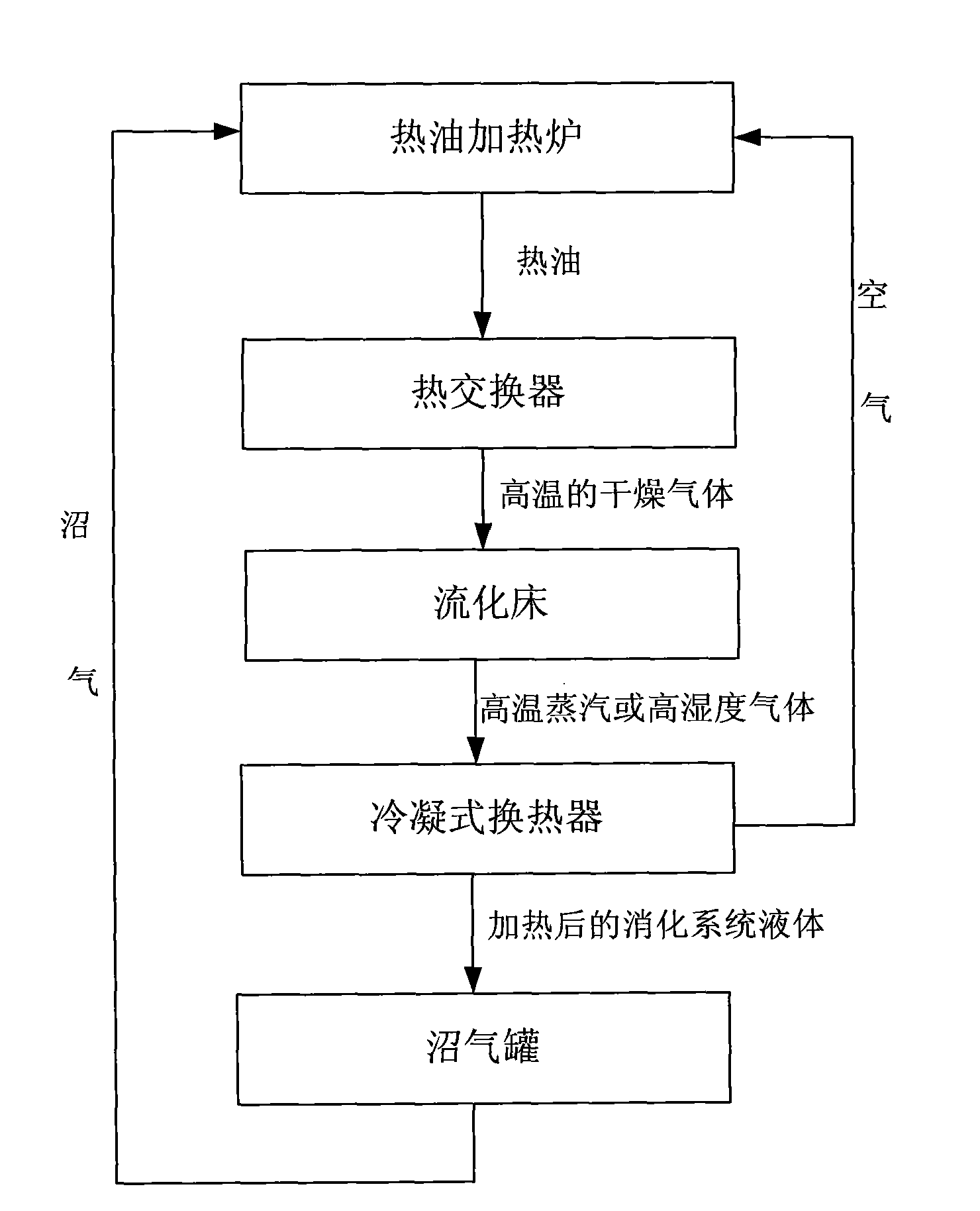

[0028] The sludge thermal drying system is mainly composed of a thermal oil heating furnace, a heat exchanger and a fluidized bed; the sludge digestion and fermentation system is mainly composed of a biogas tank, between the sludge thermal drying system and the sludge digestion and fermentation system, Set up a condensing heat exchanger, the condensing heat exchanger is divided into a high temperature end and a low temperature end, the condensing heat exchanger is provided with a pair of gas inlet and outlet, connected with the fluidized bed gas inlet and outlet; a digestive system liquid inlet; System liquid outlet, connected with biogas tank;

[0029] Wherein, if the sludge thermal drying system is composed of a thermal oil heating furnace, a heat exchanger and a non-fluidized bed drying system, the exhaust port at the hot end of the condensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com