Method for preparing cobalt octoate by using LiCoO, anode material of waste lithium battery

A positive electrode lithium cobalt oxide and waste lithium battery technology, which is applied in carboxylate preparation, organic chemistry, etc., can solve the problems of lithium cobalt oxide material discarding, environmental management hidden dangers, etc., and achieve improved extraction rate and production efficiency with low cost , the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

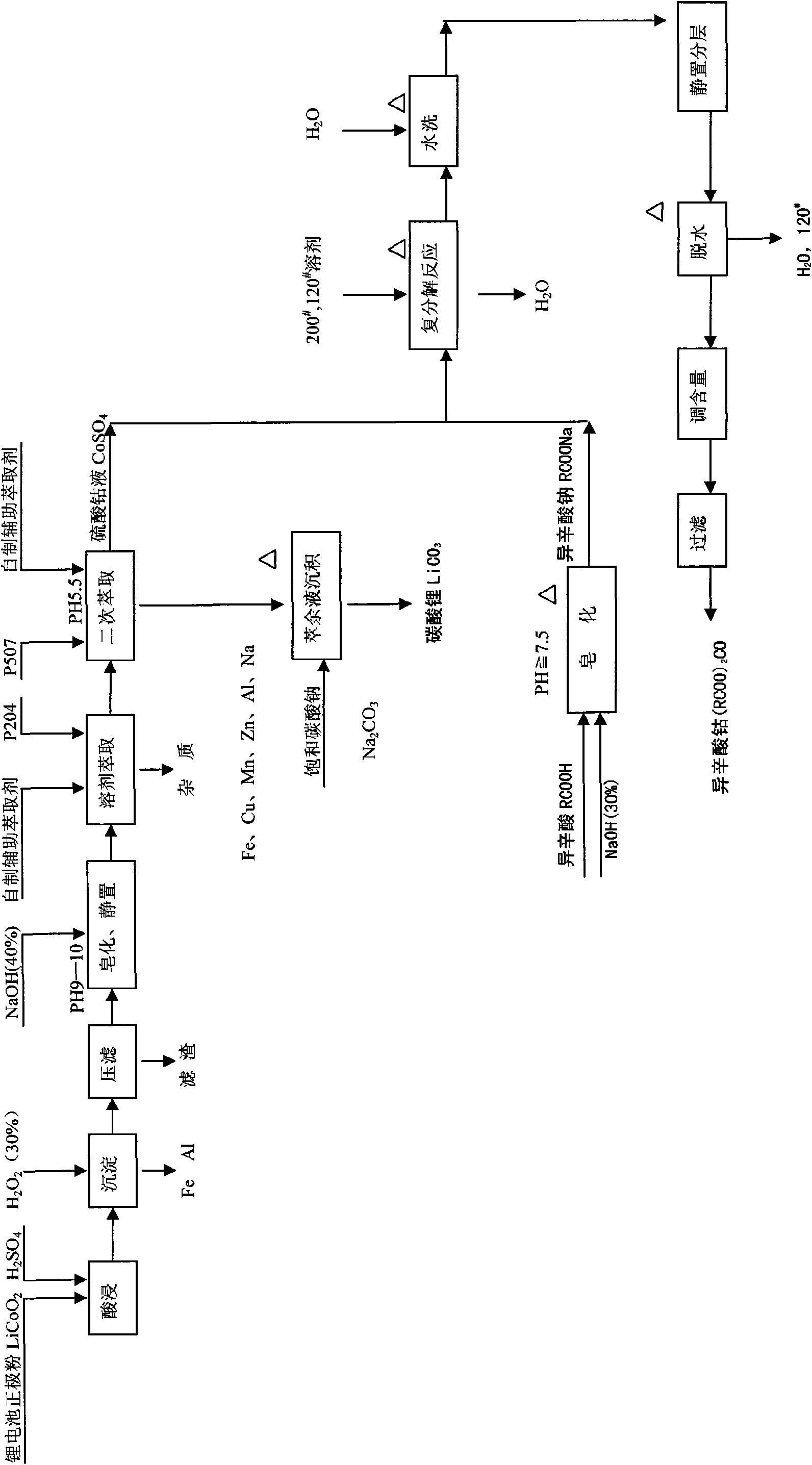

Method used

Image

Examples

Embodiment 1

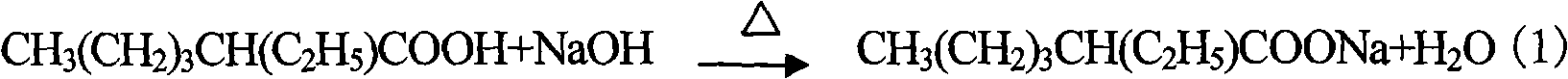

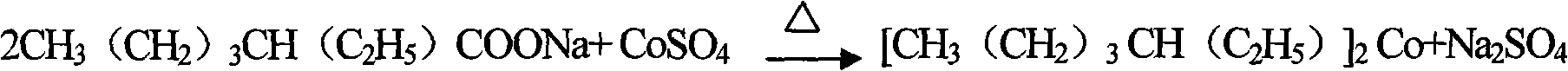

[0067] Example 1: First, put the 100-mesh lithium cobaltate powder made from the positive lithium cobaltate of the waste lithium battery into a sulfuric acid acidolysis tank with a concentration of 39% and stir, so that the lithium cobaltate powder exists in the state of a compound in each group After 2 hours, add hydrogen peroxide with a concentration of 29.5%, the amount of which is 1.5 times the weight of lithium cobaltate powder, and control the temperature at 80 ° C. Stop stirring and settling for 1 hour, so that the impurity elements and cobalt 1. The main lithium metal is precipitated in the acidolysis tank, and Fe and Al are removed to below 0.1g / L; then, the metal cation solution from which Fe and Al impurities are removed is introduced into the filter press from the acidolysis tank, and two press filtrations are performed Remove the filter residue, and then import in the static tank; adding concentration in the static tank is 40% lye NaOH to make the pH value reach 9,...

Embodiment 2

[0068]Example 2: First, put the 105-mesh lithium cobaltate powder made from the positive lithium cobaltate of the waste lithium battery into a sulfuric acid acidolysis tank with a concentration of 40% and stir, so that the lithium cobaltate powder exists in the state of a compound in each group After 2.5 hours, add 30% hydrogen peroxide in an amount twice the weight of lithium cobaltate powder, control the temperature at 85°C, stop stirring and settling for 1.5 hours, so that the impurity elements and cobalt 1. The main lithium metal is precipitated in the acidolysis tank, and Fe and Al are removed to below 0.1g / L; then, the metal cation solution from which Fe and Al impurities are removed is introduced into the filter press from the acidolysis tank, and two press filtrations are performed Remove the filter residue, and then import it into the static tank; add the lye NaOH with a concentration of 40% to the static tank to make the pH value reach 9.5, and leave it to stand for 1...

Embodiment 3

[0069] Example 3: First, the 120-mesh lithium cobaltate powder made from the positive lithium cobaltate of the waste lithium battery is put into a sulfuric acid acid hydrolysis tank with a concentration of 41% and stirred, so that the lithium cobaltate powder exists in the state of a compound in each group After 3 hours, add hydrogen peroxide with a concentration of 30.5%, the addition amount is 2.5 times the weight of lithium cobaltate powder, the temperature is controlled at 90 ° C, stop stirring and settling for 3 hours, so that the impurity elements and cobalt 1. The main lithium metal is precipitated in the acidolysis tank, and Fe and Al are removed to below 0.1g / L; then, the metal cation solution from which Fe and Al impurities are removed is introduced into the filter press from the acidolysis tank, and two press filtrations are performed Remove the filter residue, and then import in the static tank; adding concentration to the static tank is 40% lye NaOH to make the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com