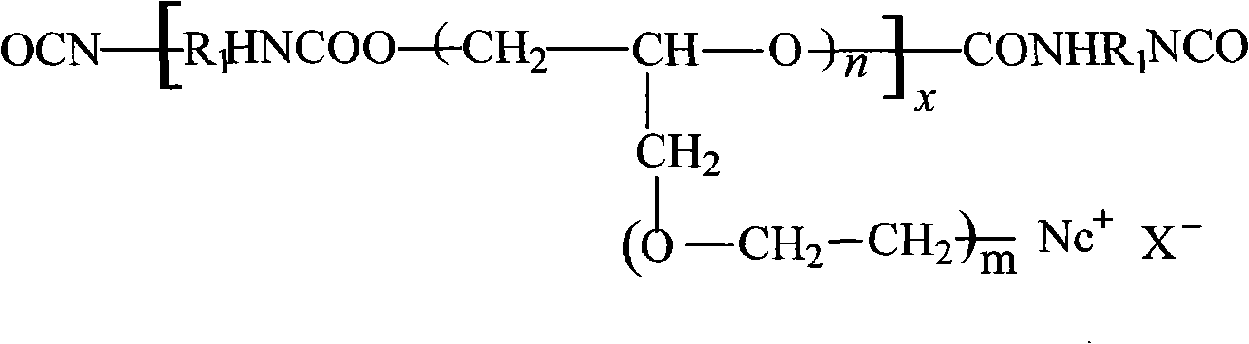

Method for preparing comb-type polyether polyurethane macromolecular ionic liquid material

A technology of polyether polyurethane and ionic liquid, applied in the field of polymer materials, can solve the problems of low glass transition temperature, low ion density, low electrical conductivity, etc., and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

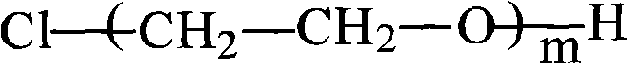

[0040] According to the molar ratio of N-methylimidazole and chloroethanol being 2, add N-methylimidazole and chloroethanol into the reaction bottle, and react at 80° C. for 24 hours under the protection of nitrogen. The reactant was washed with ether to obtain N-methyl N'-hydroxyethyl imidazolium chloride ionic liquid.

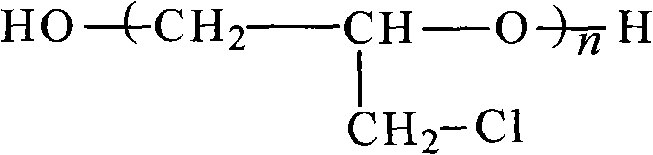

[0041] After the hydroxyl-terminated polyepichlorohydrin with a molecular weight of 1000 is protected with acetic anhydride under the action of pyridine, the N-methyl N'- Hydroxyethyl imidazolium chloride ionic liquid and sodium hydride, with acetone as solvent, reflux reaction under nitrogen protection for 10 hours. After adding water to the reaction system to remove the protection, it is extracted with dichloromethane to obtain the hydroxyl-terminated polyepichlorohydrin grafted with N-methyl N'-ethyl imidazolium chloride ionic liquid.

[0042] According to the national standard GB-T12008.3-1989 method, measure the number of moles of hydroxyl groups of hyd...

Embodiment 2

[0044] According to the ratio that the mol ratio of N-methylimidazole and monochlorodiethylene glycol is 2, add N-methylimidazole and monochlorodiethylene glycol in the reaction flask, under nitrogen protection, React at 80°C for 24 hours. The reactant was washed with ether to obtain N-methyl N'-hydroxyethoxyethyl imidazolium chloride ionic liquid.

[0045] After the hydroxyl-terminated polyepichlorohydrin with a molecular weight of 1000 is protected with acetic anhydride under the action of pyridine, the N-methyl N' -Hydroxyethoxyethyl imidazolium chloride ionic liquid and sodium hydride, with acetone as solvent, reflux reaction under nitrogen protection for 10 hours. After adding water to the reaction solution to remove the protection, it is extracted with dichloromethane to obtain the ionic liquid of hydroxyl-terminated polyepichlorohydrin grafted with N-methyl N'-oxyethyl ethyl imidazolium chloride.

[0046] According to the national standard GB-T12008.3-1989 method, mea...

Embodiment 3

[0048] According to the ratio that the mol ratio of N-methylimidazole and monochlorotriethylene glycol is 2, add N-methylimidazole and monochlorotriethylene glycol in the reaction flask, under nitrogen protection, React at 80°C for 24 hours. The reactant was washed with ether to obtain N-methyl N'-hydroxyethoxyethoxyethyl imidazolium chloride ionic liquid.

[0049] After the hydroxyl-terminated polyepichlorohydrin with a molecular weight of 1000 is protected with acetic anhydride under the action of pyridine, the N-methyl N' -Hydroxyethoxyethoxyethyl imidazolium chloride ionic liquid and sodium hydride, with acetone as solvent, reflux reaction for 10 hours under nitrogen protection. After adding water to the reaction liquid to remove the protection, it is extracted with dichloromethane to obtain the ionic liquid of hydroxyl-terminated polyepichlorohydrin grafted with N-methyl N'-ethoxyethoxyethyl imidazolium chloride.

[0050] According to the national standard GB-T12008.3-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com