Escherichia coli strain for recombined engineering

A technology of Escherichia coli and recombinant engineering, applied in the field of genetic engineering, can solve the problem of keeping the temperature uniform and difficult to control, and achieve the effect of rapid growth and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

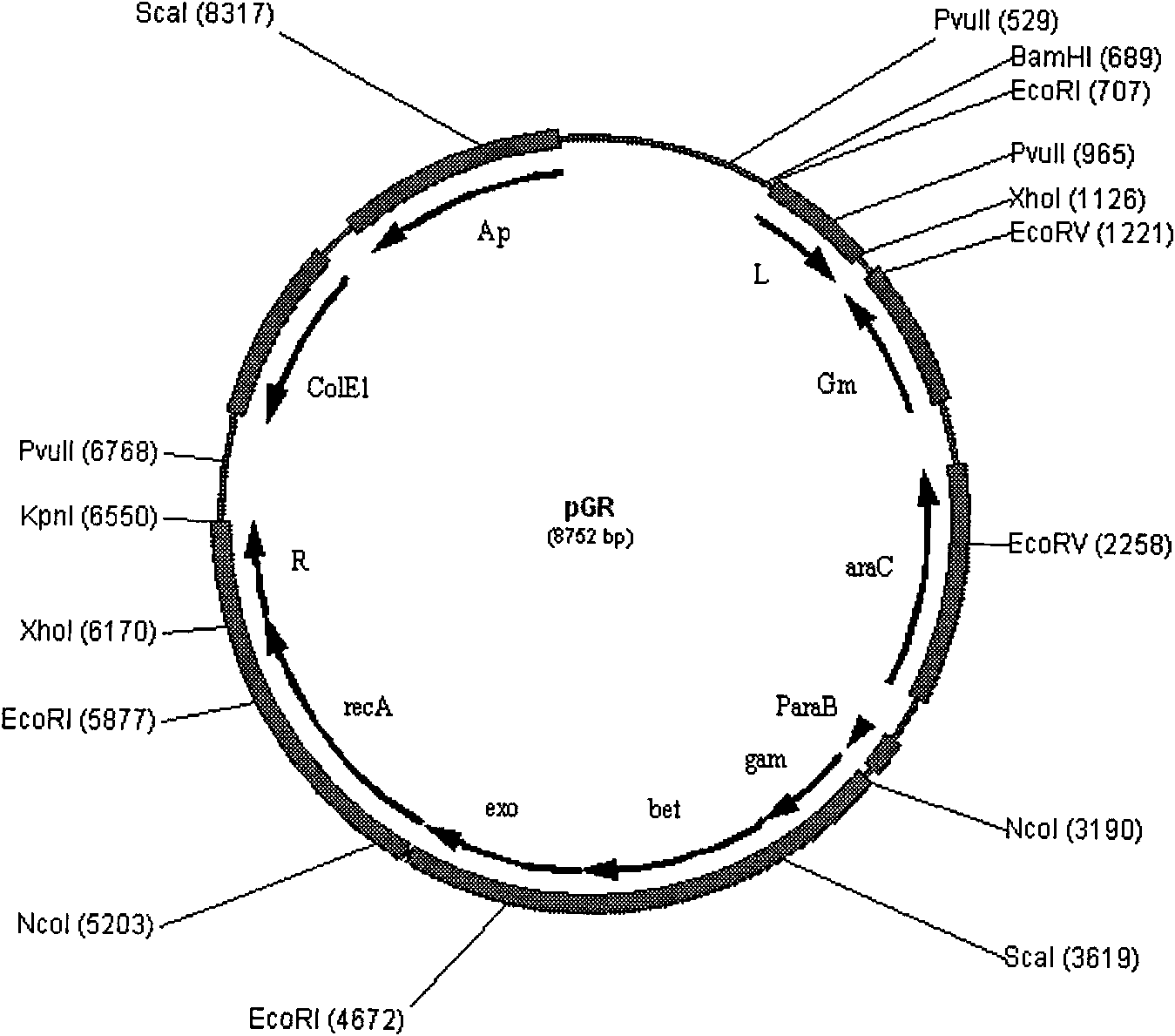

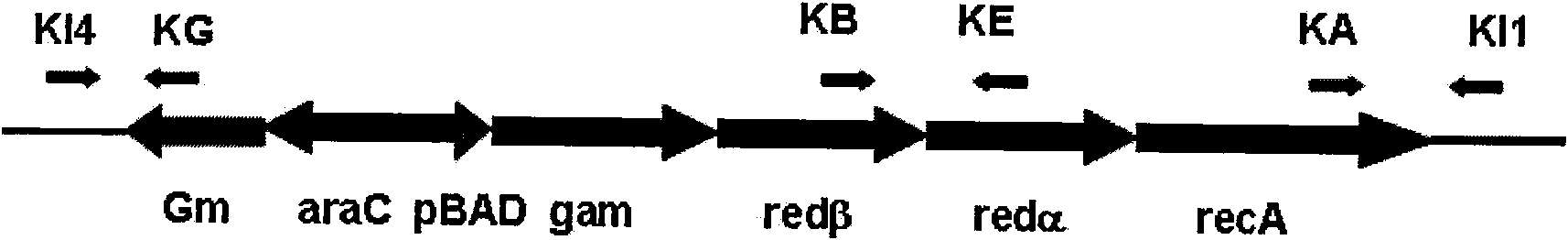

[0087] The process of Escherichia coli LS-GR construction of the present invention is as follows:

[0088] 1. Preparation of Escherichia coli DH10B electroporation competent and DNA transformation

[0089] Inoculate a freshly streaked single colony from the plate into 2ml LB liquid medium and shake overnight at 37°C, then transfer to 50ml LB at 1 / 50 volume, and shake until the cell OD 600 About 0.6. Pour the bacterial solution into a pre-cooled centrifuge tube, place in an ice bath for 10 minutes, centrifuge at 5000 rpm for 5 minutes at 4°C, and discard the supernatant. The precipitate was washed twice with 10% glycerol, and finally suspended in 200 μl of 10% glycerol, and distributed in 50 μl per tube.

[0090] Add the DNA to 50 μl of ice-thawed DH10B electroporation-competent cells, flick and mix well. The mixture was transferred to a pre-cooled 1mm electroporation cuvette on ice, and transformed by electric shock. Electroporation conditions: 1mm electroporation cup, 2...

Embodiment 2

[0153] Such as Figure 4 As shown in the schematic diagram of the experimental process, this patent is to test the function of the recombinant engineering of Escherichia coli LS-GR, and the plasmid pACYC184 ( Figure 5 ) on the tetracycline resistance gene (Tc) was replaced by the kanamycin resistance gene (neo), and the resulting new plasmid was named pAEN ( Image 6 ).

[0154] 1. Amplification of the kanamycin resistance gene (neo) with a homology arm

[0155] Design primers:

[0156] AEN1: 5′- ATGTTTGACAGCTTATCATCGATAAGCTTTAATGCGGTAGTTTATCACAG TATGGACAGCAAGCGAACCGG-3' (SEQ ID NO. 17)

[0157] AEN2: 5′- TTGATTGGCTCCAATTCTTGGAGTGGTGAATCCGTTAGCGAGGTGCCGCC TCAGAAGAACTCGTCAAGAAG-3' (SEQ ID NO. 18)

[0158] The first 50 bases of the primer are the homology arms (underlined) at both ends of the Tc gene on the pACYC184 plasmid, and the following bases are the two ends of the neo gene on the pKD4 plasmid.

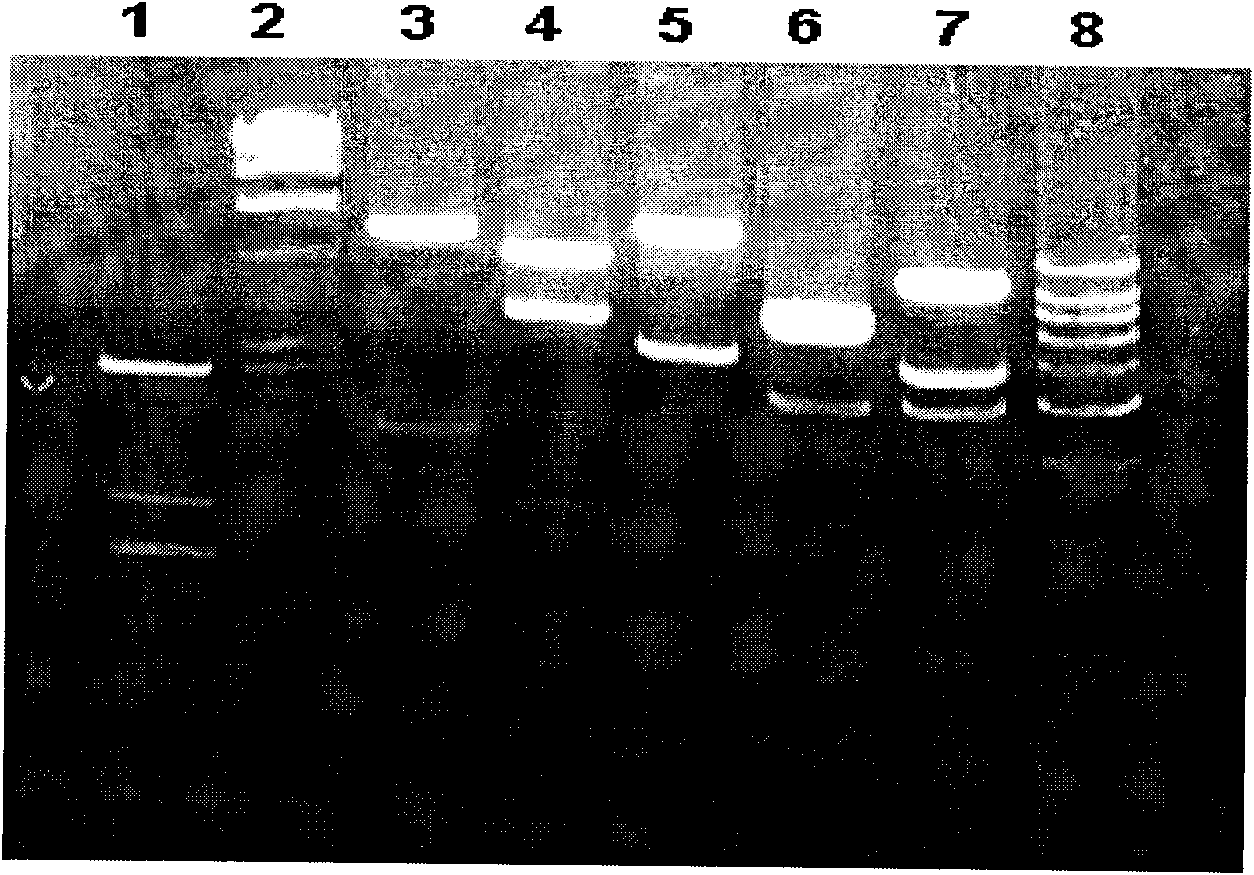

[0159] A 0.8 kb neo gene was amplified by PCR using the pKD4 tem...

Embodiment 3

[0170] Using the function of recombination engineering of Escherichia coli LS-GR, the single-copy plasmid pECBAC1 ( Figure 12 ) The chloramphenicol resistance gene (Cm) was replaced by the kanamycin resistance gene (neo), and the resulting new plasmid was named pBACN ( Figure 13 ).

[0171] 1. Amplification of the kanamycin resistance gene (neo) with a homology arm

[0172] Design primers:

[0173] CEN1: 5′- TAAGGGCACCAATAACTGCCTTAAAAAAATTACGCCCCGCCCTGCCACT C TATGGACAGCAAGCGAACCGG-3' (SEQ ID NO.19)

[0174] CEN2: 5′- GCGTATTTTTTGAGTTATCGAGATTTTCAGGAGCTAAGGAAGC TAAAATG TCAGAAGAACTCGTCAAGAAG-3' (SEQ ID NO. 20)

[0175] The first 50 bases of the primer are the homology arms (underlined) at both ends of the Cm gene on the pECBAC1 plasmid, and the following bases are the two ends of the neo gene on the pKD4 plasmid.

[0176] A 0.8 kb neo gene was amplified by PCR using the pKD4 template, detected by electrophoresis on 1% agarose gel, and the PCR product was precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com