Single-stage forward type high-frequency linked inverter

A high-frequency transformer and forward-type technology, which is applied in the field of power electronic converters, can solve the problems of not maximizing device utilization, limiting the maximum duty cycle of switching tubes, and high voltage stress of switching tubes, so as to improve the equivalent duty cycle. Duty ratio and inductor current pulsation frequency, increase equivalent switching frequency and equivalent duty ratio, and reduce the effect of voltage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

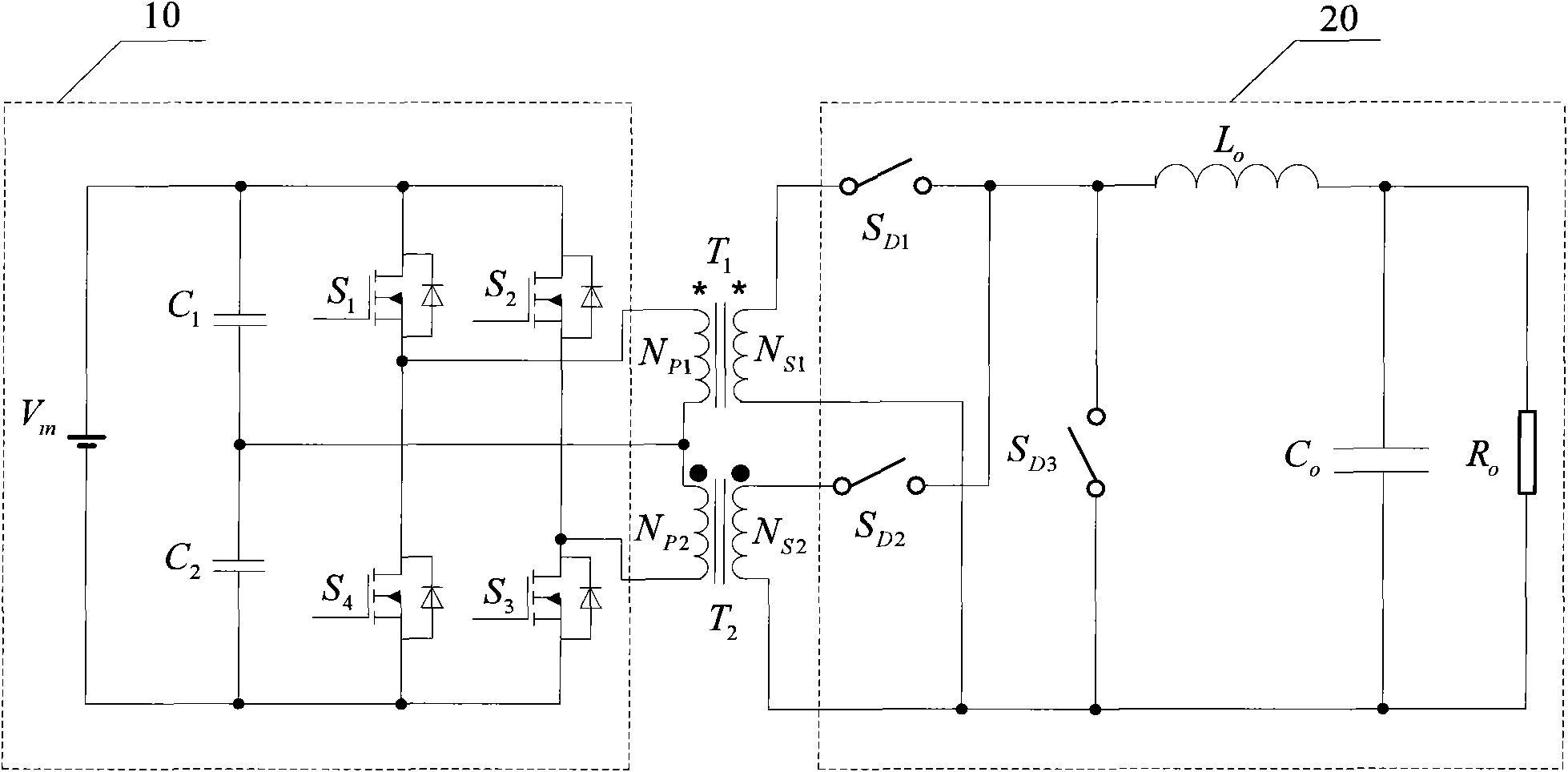

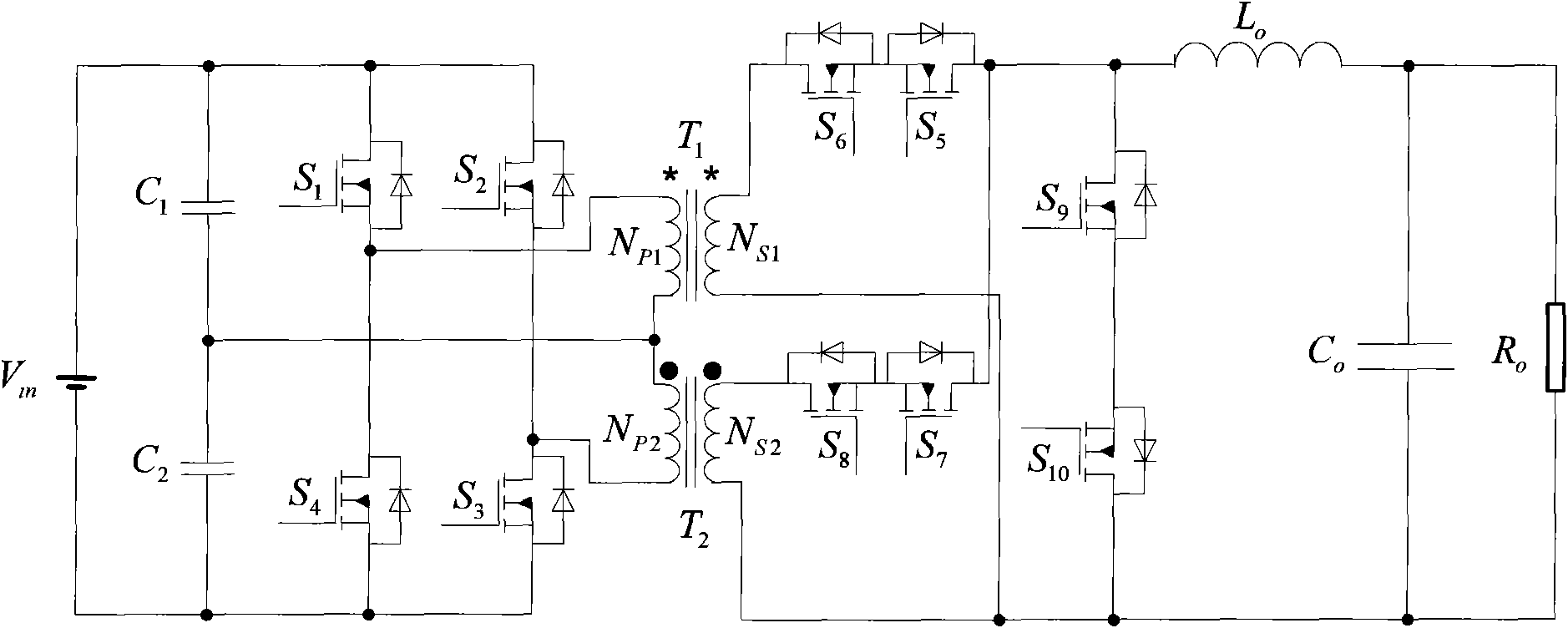

[0021] like figure 1 As shown, the structure of the single-stage forward high-frequency link inverter of the present invention includes: a primary side circuit 10, a first high-frequency transformer T 1 , the second high frequency transformer T 2 and the secondary side circuit 20, wherein: the primary side circuit 10 includes a DC power supply V in , the first voltage dividing capacitor C 1 , the second voltage dividing capacitor C 2 , the first power switch tube S 1 , the second power switch tube S 2 , the third power switch tube S 3 and the fourth power switch S 4 , DC supply V in The positive poles of are respectively connected to the first voltage dividing capacitor C 1 One end of the first power switch tube S 1 The drain and the second power switch S 2 the drain of the DC supply V in The negative poles of are respectively connected to the second voltage dividing capacitor C 2 One end of the fourth power switch tube S 4 The source and the third power switch S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com