Method for processing light hydrocarbons oxidation sweetening tail gas

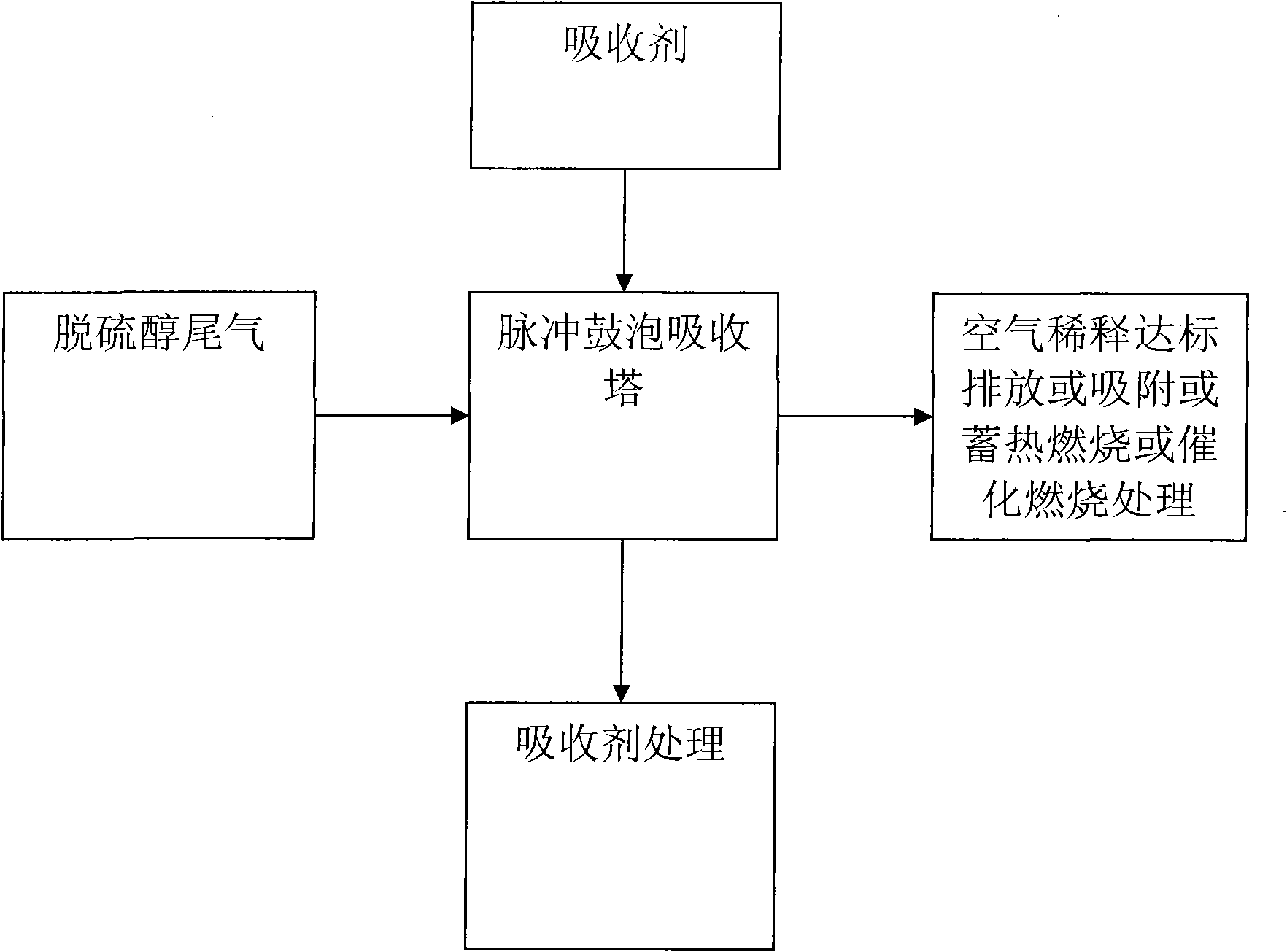

A technology for oxidatively removing mercaptans and tail gas, applied in chemical instruments and methods, separation methods, and refining hydrocarbon oil, etc., can solve the problems of economic decline, economic impact, increase in operating costs, etc., to improve absorption rate and operation flexibility, The effect of improving the gas-liquid contact effect and reducing the scale of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Small lab experiments.

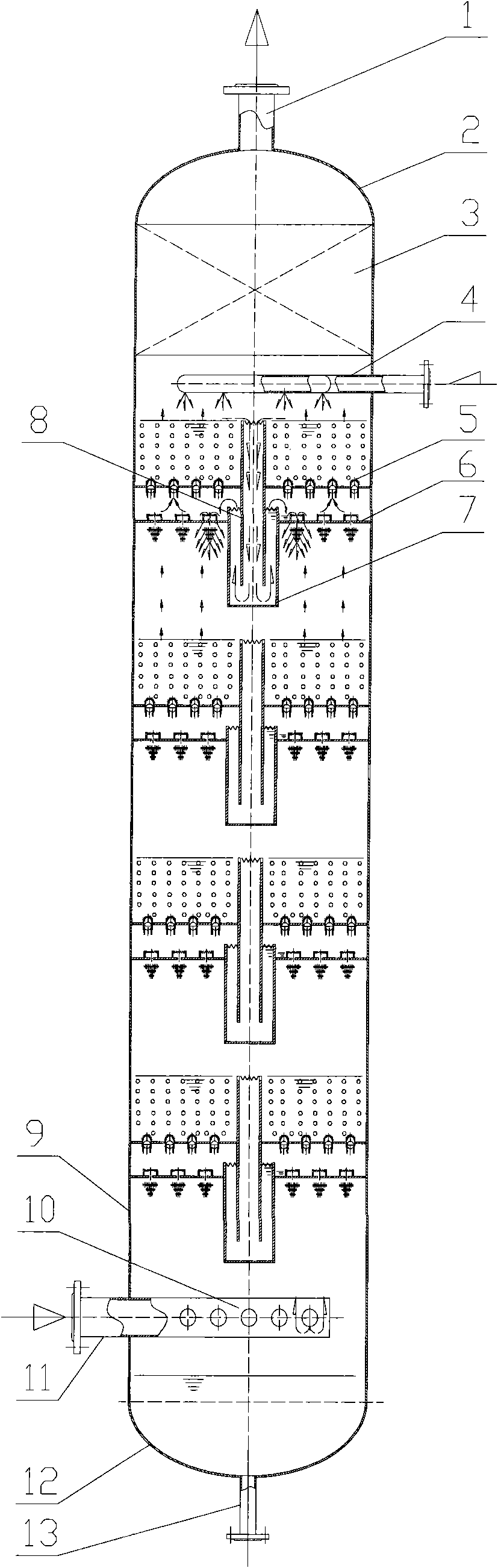

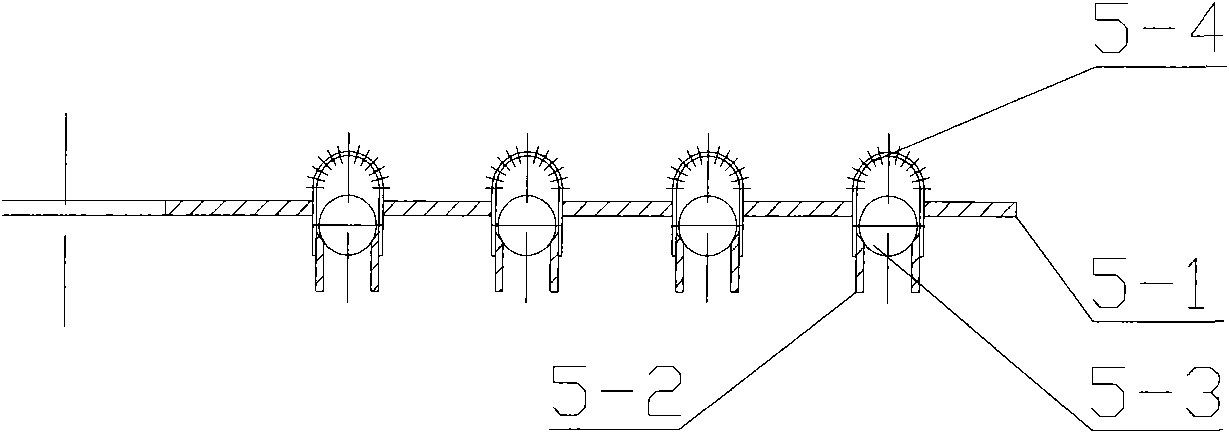

[0029] A first-stage pulse bubbling absorption tower is adopted, including a bubbling absorption zone, and the internal components of the absorption tower are determined according to the preferred data in the specific embodiment. The thickness of the liquid phase layer in the bubbling absorption zone is 400mm, and the height of the spray section is 300mm. The absorbents were three different diesel fractions. After absorption, the tail gas is diluted with air and then discharged.

[0030] Gasoline fraction (distillation range 70-170°C) and petroleum ether (distillation range 30-60°C) are simulated by bubbling air through oxidative sweetening tail gas to conduct absorption and recovery tests. The inlet pressure of the gas phase is 0.1MPa (gauge pressure). The outlet is normal pressure, and the results are listed in Table 1, Table 2, and Table 3. (Nm 3 Indicates the standard state cubic meter)

[0031] Table 1 The absorption effect of differen...

Embodiment 2

[0038] An enterprise gasoline oxidative sweetening tail gas contains 32v% hydrocarbons (volume fraction, the same below), the tail gas temperature is 53°C, the oxygen content is 17v%, the pressure is 0.2MPa (gauge pressure), and the flow rate is 70Nm 3 / h or so. A three-stage pulse bubbling absorption tower is adopted, including three bubbling absorption zones and three spraying absorption zones, and the internal components of the absorption tower are determined according to the preferred data in the specific embodiment. The thickness of the liquid layer in the bubbling absorption zone is 350mm, and the height of the spray section is 250mm. The absorbent is catalytic diesel oil, and the liquid-gas ratio is 100L / m 3 , The operating temperature is 25-40°C. The absorbed catalytic diesel oil enters the hydrogenation unit together with other catalytic diesel oils, and the absorbed tail gas is led to the air cooler inlet of the catalytic cracking unit.

[0039] After absorption t...

Embodiment 3

[0041] Same as Example 2, the exhaust gas after absorption treatment, the amount is about 50Nm 3 / h, the concentration of organic matter is about 20g / Nm 3 , the hydrocarbon emission rate was about 1 kg / h. Dilute with air to a total hydrocarbon concentration of 50093000mg / Nm 3 , using a conventional heat storage combustion device for treatment, and the purified gas meets the current national emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com