Processing method for reducing solubility of polyvinyl alcohol (PVA) film

A treatment method, polyvinyl alcohol technology, applied in the treatment field of reducing the solubility of polyvinyl alcohol film, can solve problems such as unsatisfactory, reduced solubility, decreased solubility, etc., to prevent moisture from entering, reduce solubility, and crystallinity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

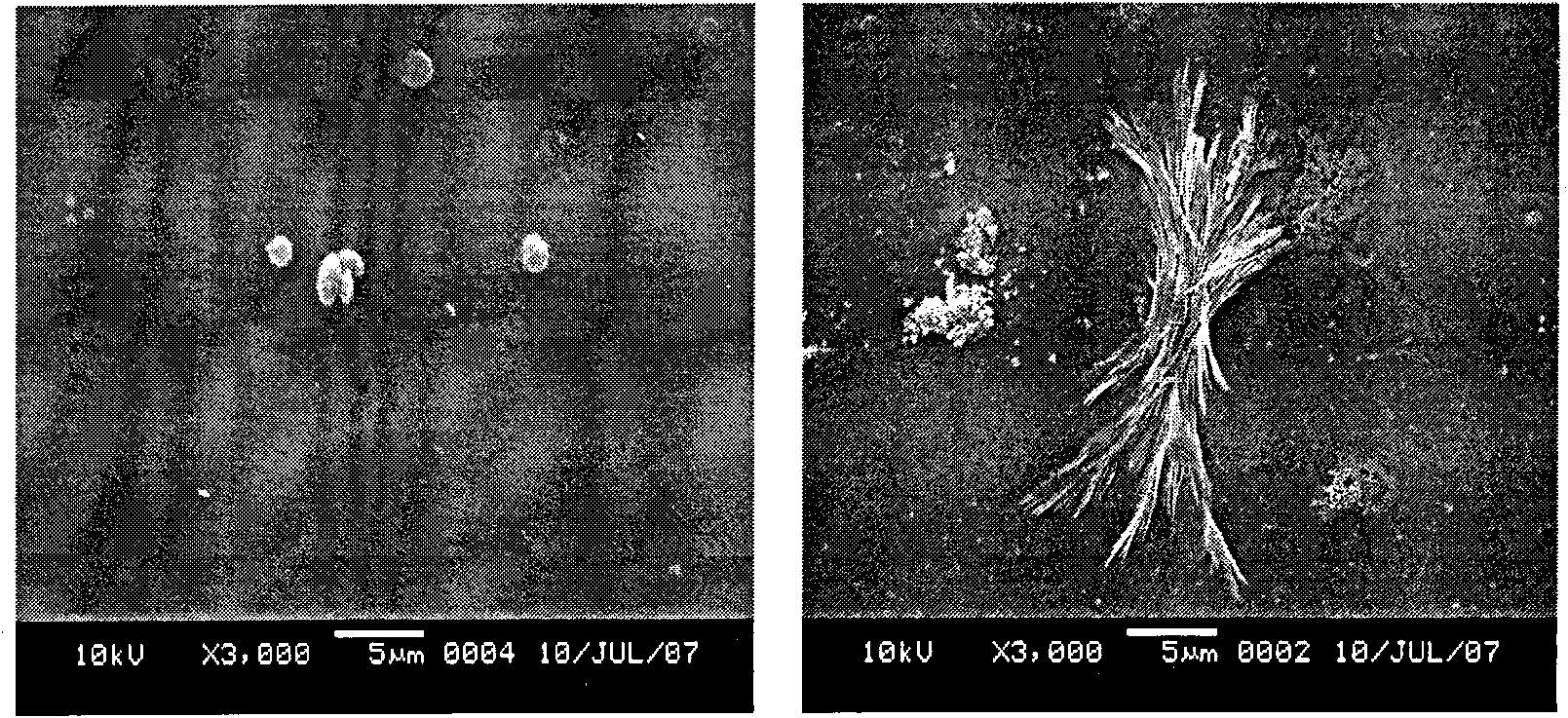

Image

Examples

Embodiment 1

[0015] (1) Weigh 6 grams of polyvinyl alcohol particles (specification: 1799, degree of polymerization is 1700, degree of alcoholysis is 99%) with a microbalance, dissolve in 200 milliliters of deionized water, heat and stir at 95°C for 2-3 hours, and The boiled slurry is vacuumed to remove air bubbles, slowly poured on the polyester film, and then peeled off after natural drying to form a film. The thickness of the film is measured by a thickness gauge to be about 40 μm.

[0016] (2) Put water in the desiccator, put the PVA film on the partition, and do not touch the water surface. Try to seal the desiccator and place it for 24 hours to make the film completely absorb moisture, and the moisture regain rate reaches 78.31%.

[0017] (3) Regulating atmospheric pressure plasma treatment parameters (using gas as He / O 2 , the processing power is 80-100W, the frequency is 13.56MHz, and the distance between the nozzle and the substrate is 2-4mm), and then the wet-balanced PVA film i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com