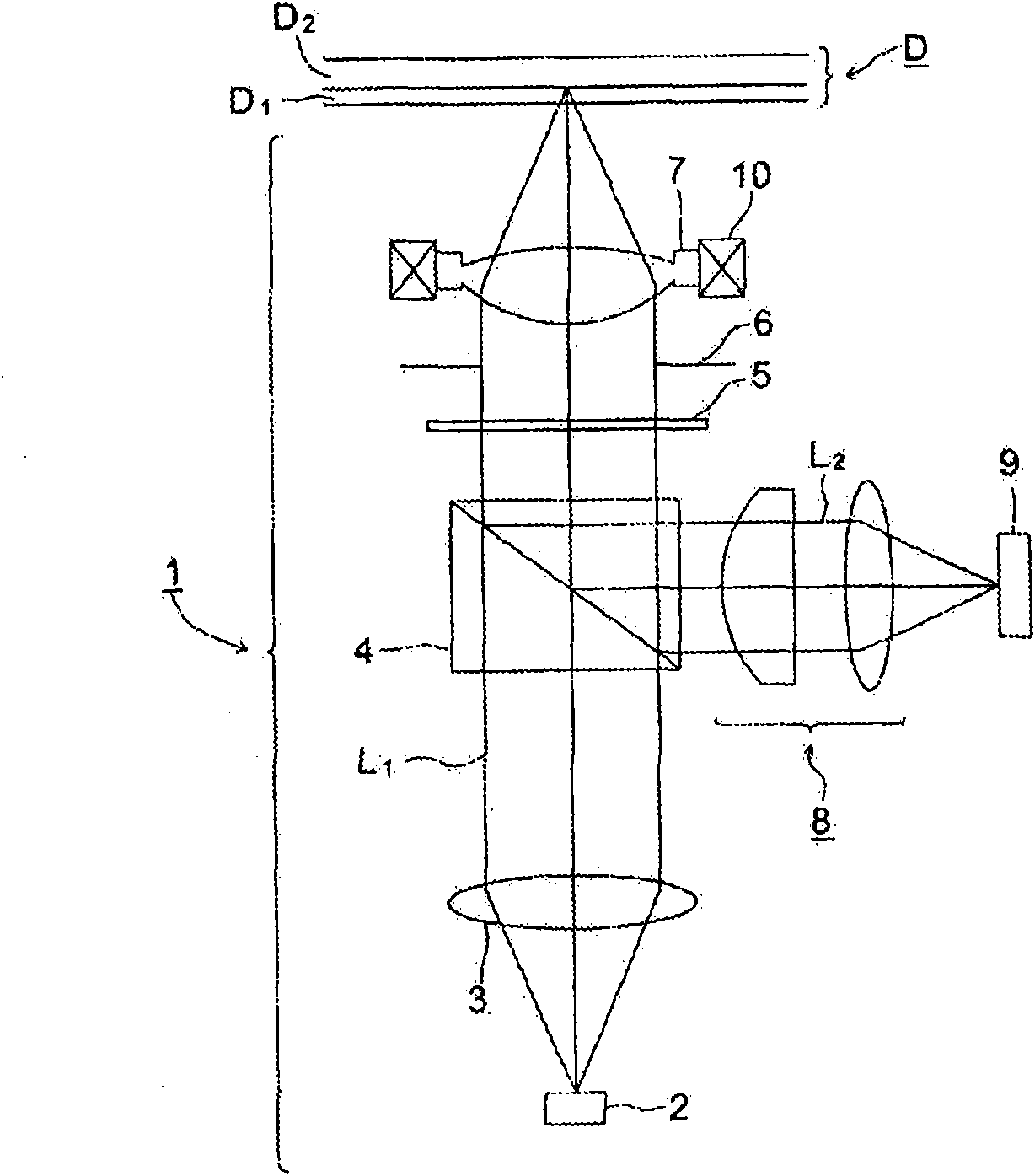

Organic/inorganic composite material for optical applications and optical element

An inorganic composite material, organic technology, applied in the direction of optical components, optics, optical recording head, etc., can solve the problem of light transmittance reduction, achieve the effect of improved temperature dependence and excellent light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

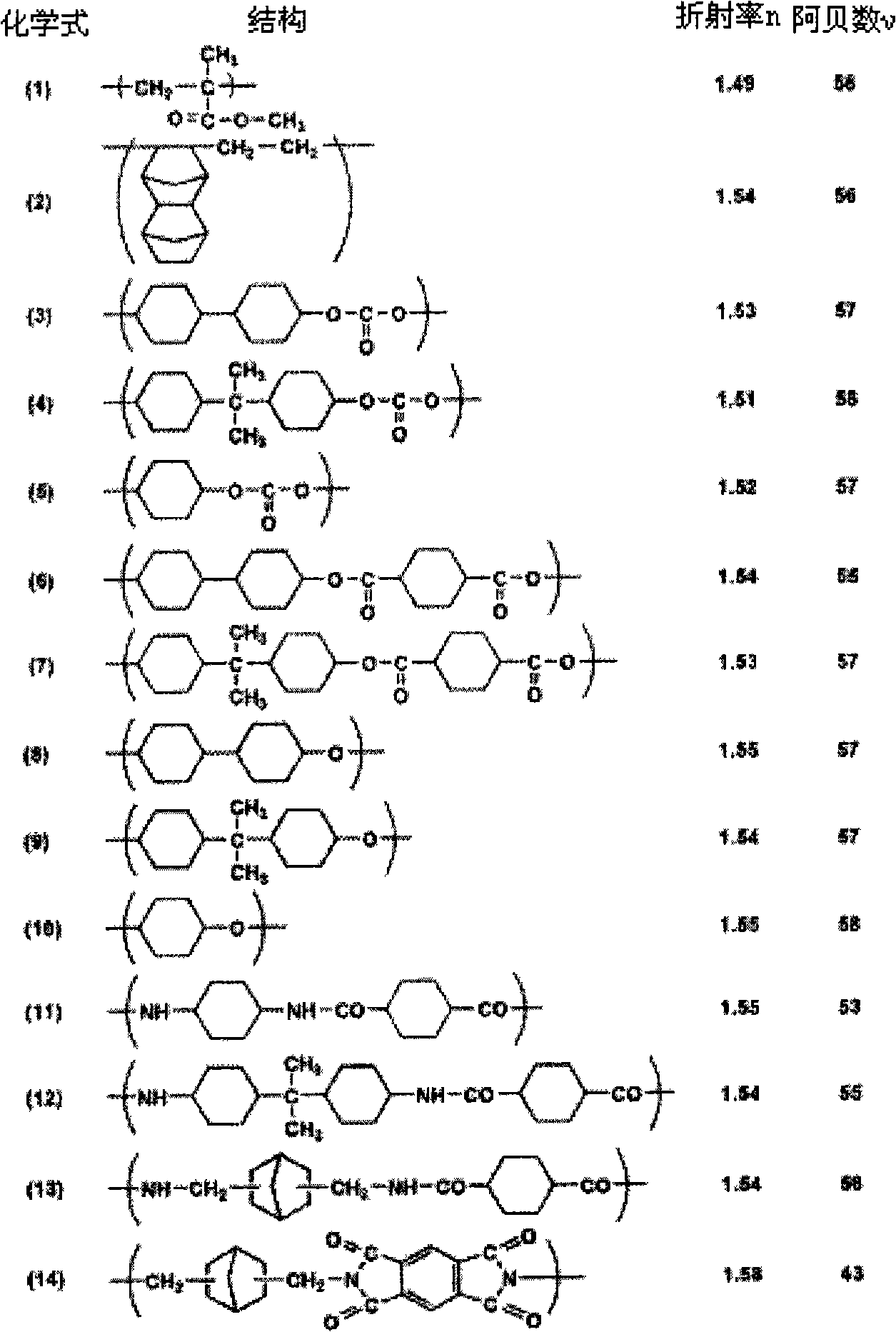

Method used

Image

Examples

Embodiment 1

[0171] "Preparation of Inorganic Microparticles"

[0172] "Preparation of Inorganic Microparticles A"

[0173] Inorganic fine particles A were prepared according to the steps shown below.

[0174] (dispersion process)

[0175] To 7.2 g of alumina (alumina C produced by Nippon Aerosil Co., Ltd., primary particle size 13 nm), 50 ml of pure water, 390 ml of special-grade ethanol (manufactured by Kanto Chemical Co., Ltd.), and 22 ml of 28% ammonia (manufactured by Kanto Chemical Co., Ltd.) were added to prepare a solution. To this solution, 0.72 g of tetraethoxysilane (LS-2430 manufactured by Shin-Etsu Chemical Co., Ltd.) was added, and Ultra Apex-Mill UAM-015 (manufactured by Kotobuki Kogyo Co., Ltd.) was used to disperse at a peripheral speed of 6 m / sec for 1 hour using 0.05 mm beads. . Then, 0.72 g of tetraethoxysilane (LS-2430 manufactured by Shin-Etsu Chemical Co., Ltd.) was further added to this dispersion liquid, and it stirred for 1 hour in the same manner as above.

...

Embodiment 2

[0214] "Production of Samples"

[0215] "Production of Sample 7"

[0216] Add 100 parts by mass of curable resin 3,4-epoxycyclohexenylmethyl-3',4'-epoxycyclohexene carboxylate (Seloxide 2021 manufactured by Daicel Chemical Industry Co., Ltd.) 100 parts by mass of methyl hexahydrophthalic anhydride (Epiclon B-650 manufactured by Dainippon Ink Chemical Industry Co., Ltd.), 2-ethyl-4-methylimidazole (manufactured by Shikoku Chemical Industry Co., Ltd. 2E4MZ) as a curing accelerator ) 3 parts by mass, 0.1 parts by mass of phenolic antioxidant (tetrakis(methylene-3-(3', 5'-di-tert-butyl-4'-hydroxyphenylpropionate) methane) as a stabilizer and Phosphorus stabilizer (2,2'-methylenebis(4,6-di-tert-butylphenyl)-2-ethylhexyl phosphite) 0.1 parts by mass, here, add the Inorganic microparticles A were mixed and dispersed using Labo Plastomill (manufactured by Toyo Seiki Seisakusho Co., Ltd., Labo Plastomill KF-6V). After the dispersion was decompressed and degassed, it was poured into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com