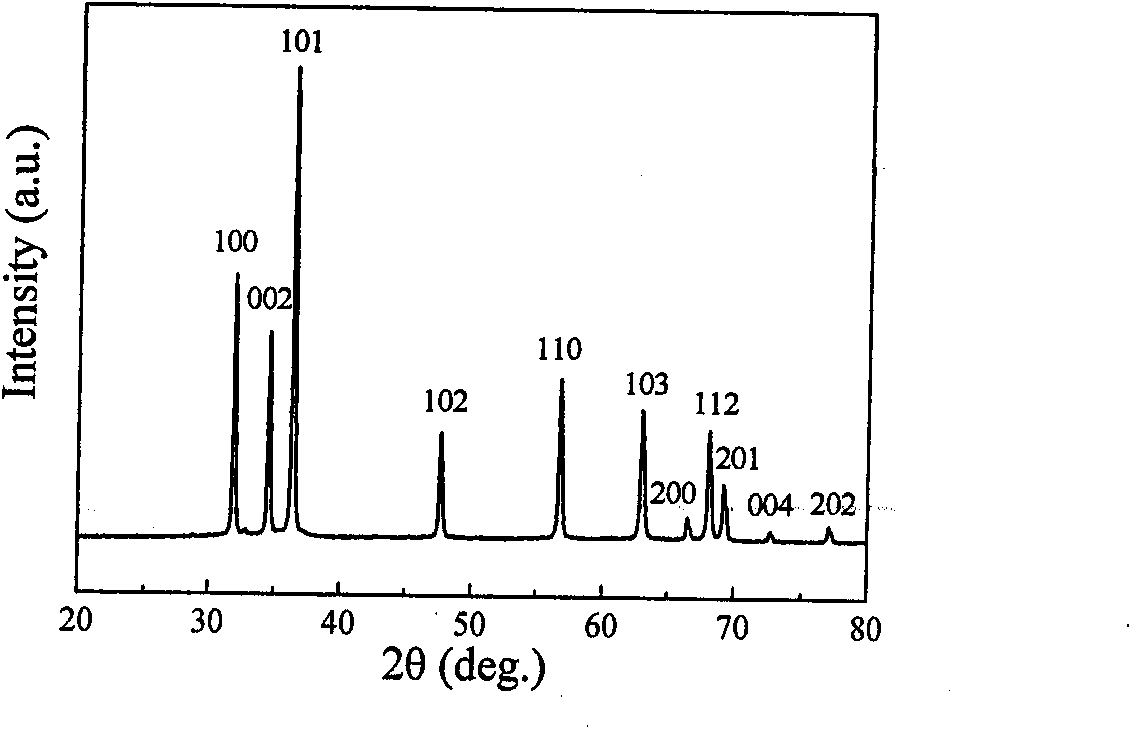

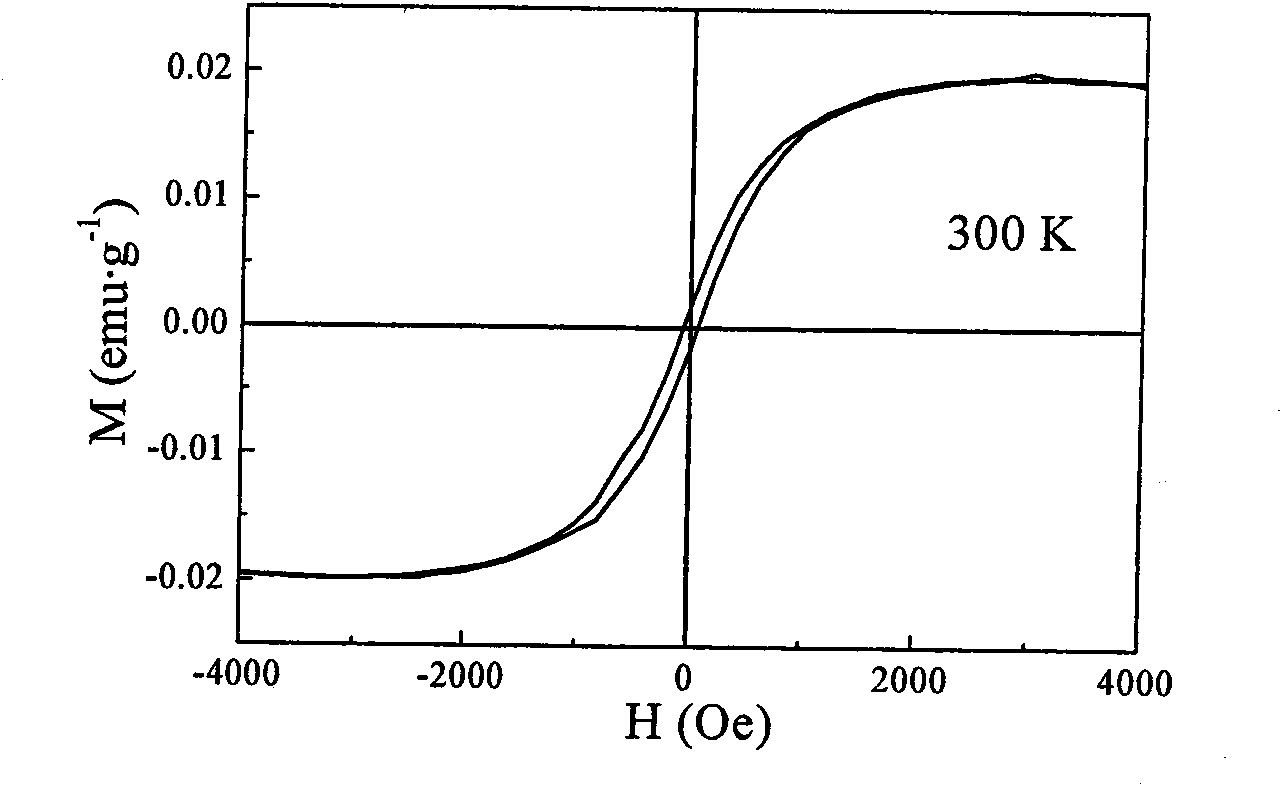

Preparation method of nano ZnO material having room temperature ferromagnetic property

A room-temperature ferromagnetism and nano-material technology, applied in nano-structure manufacturing, magnetic objects, nano-technology, etc., can solve problems such as difficult to improve the room-temperature magnetic properties of ZnO, and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

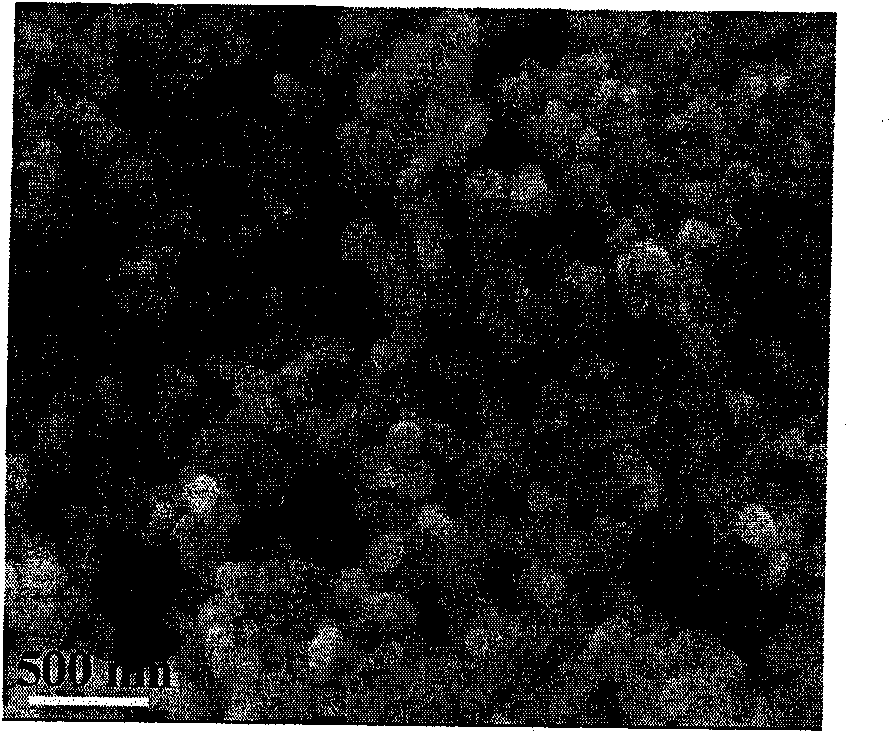

example 1

[0015] The concrete processing steps of this example are as follows:

[0016] Weigh an appropriate amount of Zn(Ac) according to the molar ratio of 1:10 2 2H 2 O and NaOH, and then add the two into an appropriate amount of absolute ethanol, so that Zn(Ac) 2 2H 2 The concentration of O is 0.0125mol / L, and then the solution is ultrasonicated for 30min and then transferred to a 50mL hydrothermal reactor liner, sealed and kept at 120°C for 5h, and the clear liquid is removed after natural cooling, and the obtained product is centrifuged and used The samples were washed with deionized water and absolute ethanol, and finally dried at 70°C for 10 h. Put the dried ZnO nanorods into a strong magnetic field heating furnace for magnetic field heat treatment. The treatment temperature is 700°C, the treatment time is 2h, the atmosphere is air, and the magnetic field is 12T during the heat treatment process, and from the beginning to the end of the heat treatment process A constant magn...

example 2

[0019] ZnO nanoparticles were prepared by chemical water bath deposition. Concentration of 20mmol / L Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine (C 6 h 12 N 4 ) in ethanol solution at 70°C in a water bath for 20 h. Afterwards, the precipitate obtained is centrifuged, washed, and dried to obtain ZnO nanoparticles. Then ZnO nanoparticles are placed in a strong magnetic field heating furnace with an air atmosphere for magnetic field heat treatment. The treatment temperature is 400°C, the treatment time is 5h, the atmosphere is air, and the magnetic field is 12T during the heat treatment process. A constant magnetic field was applied until the end, and the samples were taken out after natural cooling to room temperature.

example 3

[0021] Preparation of ZnO nanowires. ZnO nanowires were prepared by chemical vapor deposition. Then place the ZnO nanowires in a strong magnetic field heating furnace with an air atmosphere for magnetic field heat treatment. The treatment temperature is 800°C, the treatment time is 3h, the atmosphere is air, and the magnetic field is 12T during the heat treatment process. A constant magnetic field was applied until the end, and the samples were taken out after natural cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com