Etching bath composition for transparent conductive film

A technology of transparent conductive film and corrosive solution, which is applied in the direction of surface etching composition, chemical instrument and method, etc., and can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

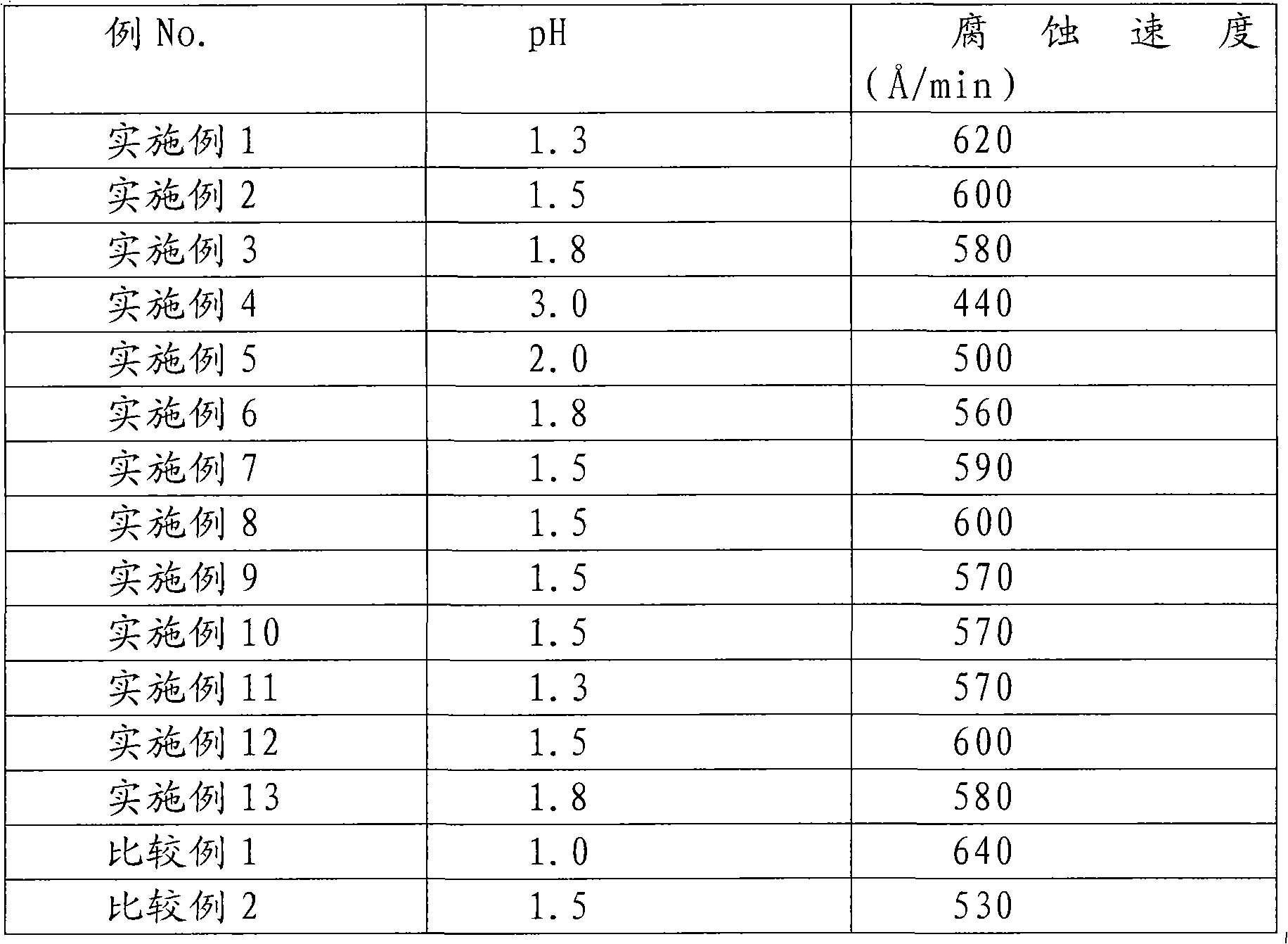

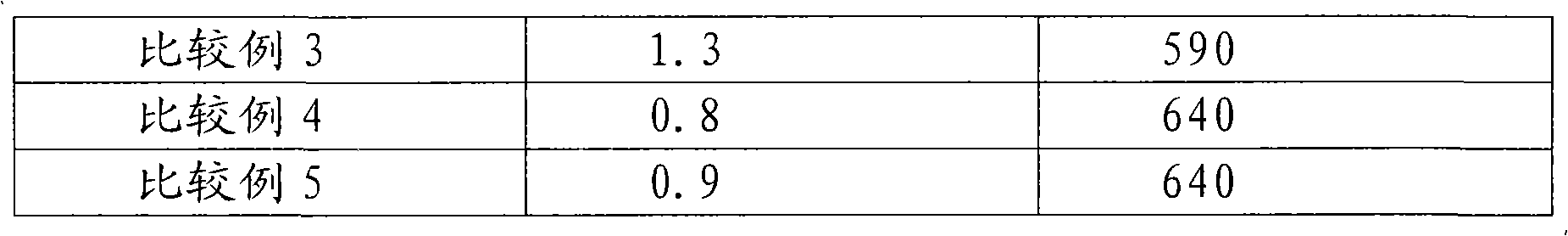

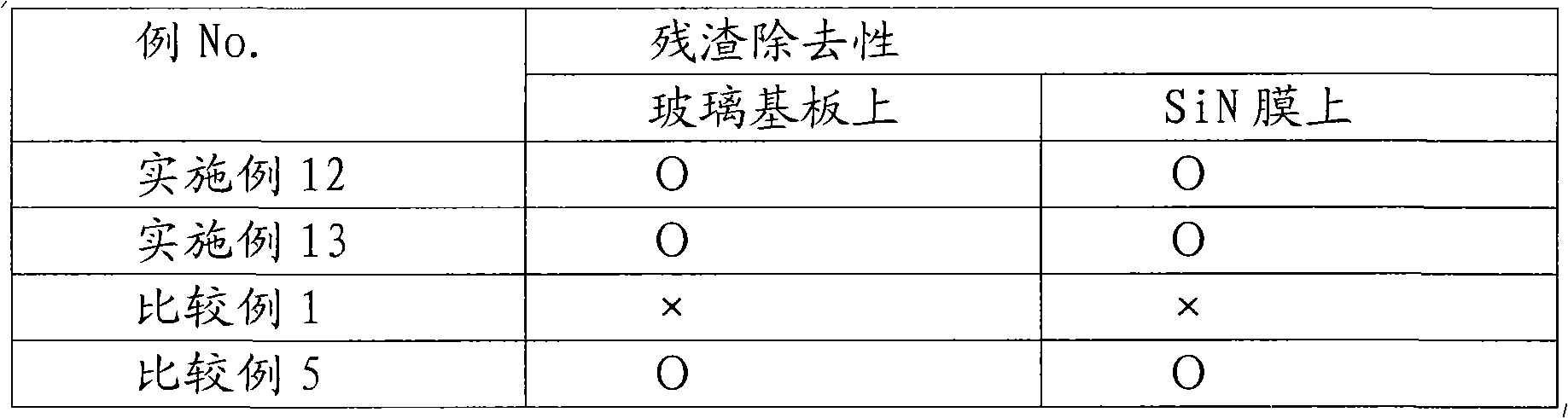

[0064] (Composition of corrosion solution)

[0065] Table 1 shows the compositions of the etching solutions of Examples and Comparative Examples of the present invention.

[0066] Table 1

[0067] Example No.

basic compound

polysulfonic acid compound

water

Example 1

3.4% by weight

TMAH

1.5% by weight

-

Residual amount

Example 2

3.4% by weight

TMAH

2.0% by weight

-

Residual amount

Example 3

3.4% by weight

TMAH

2.7% by weight

-

Residual amount

Example 4

3.4% by weight

TMAH

3.8% by weight

-

Residual amount

Example 5

0.5% by weight

TMAH

0.4% by weight

-

Residual amount

Example 6

1.0% by weight

TMAH

0.7% by weight

-

Residual amount

Example 7

5.0% by weight

TMAH

3.2%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com