Method for comprehensively utilizing tail gas of sludge phosphorus-prepared sodium hypophosphite

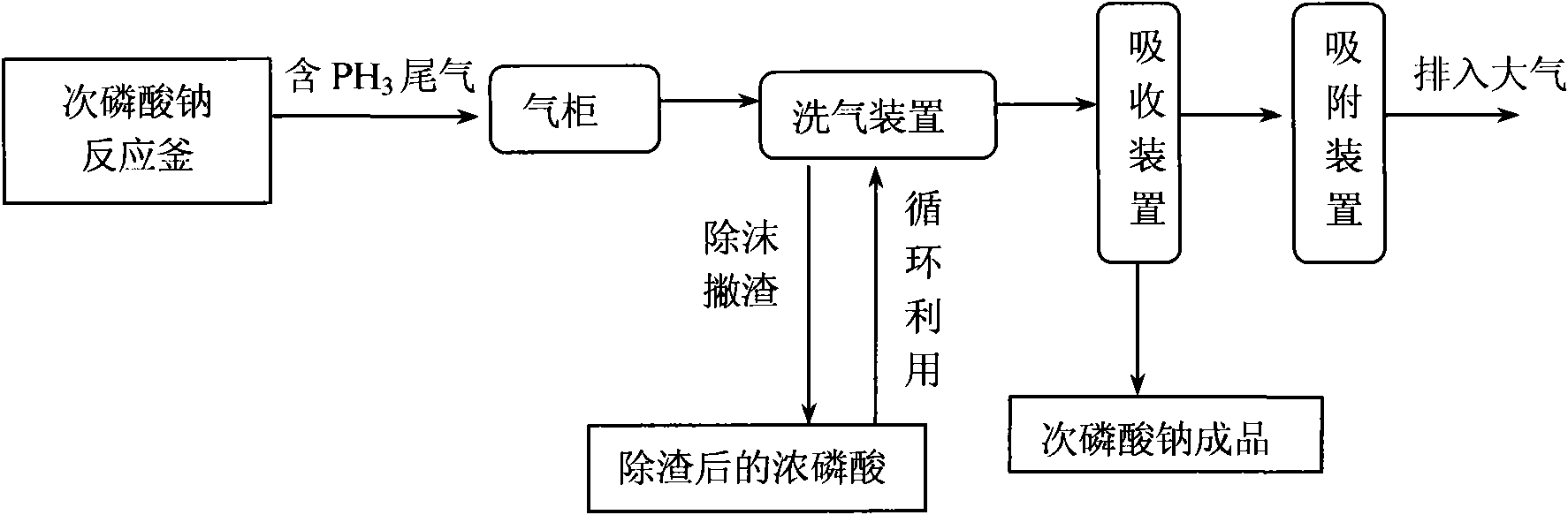

A technology of sodium hypophosphite and sodium hypochlorite solution, applied in the directions of hypophosphorous acid, phosphorus oxyacid, separation method, etc., can solve the problems of long process, high risk, environmental pollution, etc., and achieves improved absorption efficiency, good gas scrubbing effect, The effect of high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

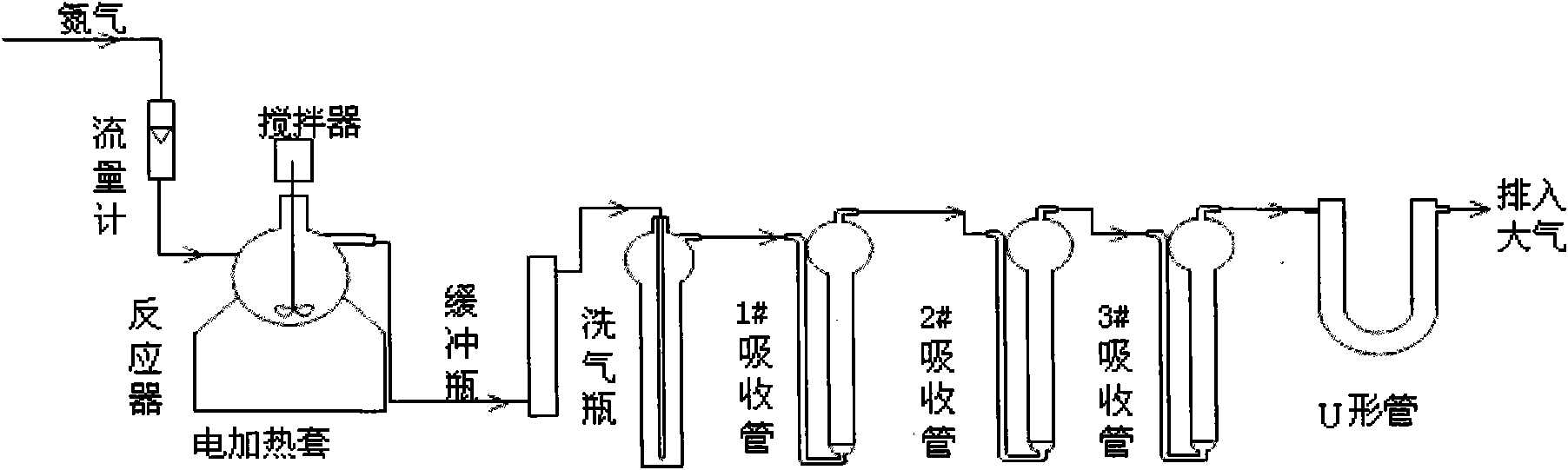

[0030] Get 21.03g of mud phosphorus from Kunyang Phosphate Fertilizer Factory with an average phosphorus content of 33.1%, containing about 6.98g of phosphorus. According to the water-to-phosphorus ratio of 105:1 and the alkali-to-phosphorus ratio of 3.5:1, the proportioning ratio of sodium hydroxide and calcium hydroxide is 5:1 into the reactor, the temperature is controlled at 85°C for reaction, and the flow rate of carrier gas nitrogen is 20mL / min.

[0031] The washing liquid is 80% concentrated phosphoric acid;

[0032] Fill the primary absorption tube with 100mL of 0.75% NaClO solution, pH=9;

[0033] Fill the secondary absorption tube with 100mL of 7% NaClO solution, pH=9;

[0034] Fill the tertiary absorption tube with 100mL of 7% NaClO solution, pH=13;

[0035] Put 80.01 g of modified activated carbon into the adsorption tube.

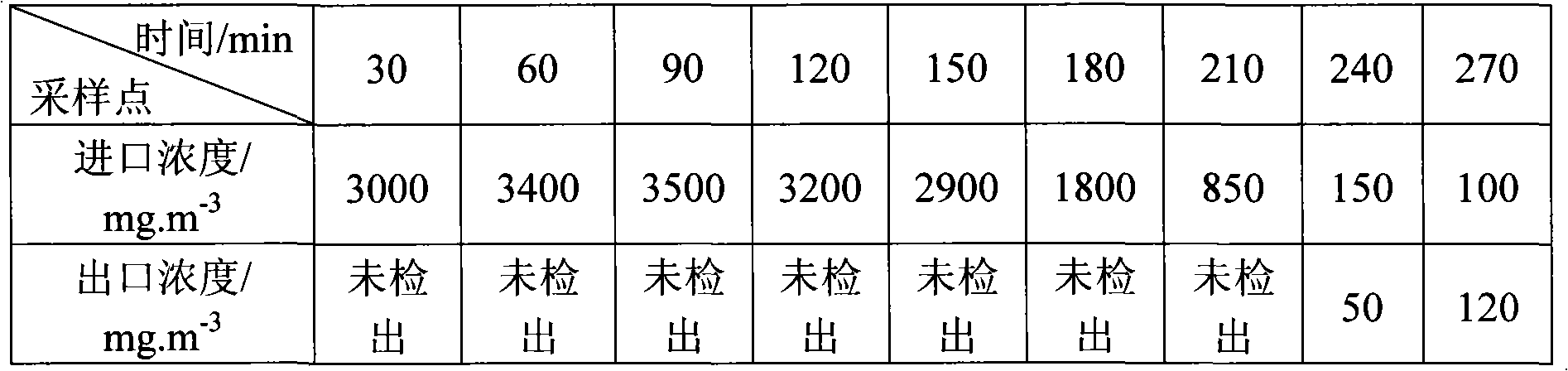

[0036] The results of the absorption test are as follows:

[0037] Table 1 Absorption test results

[0038] test results

re...

Embodiment 2

[0043] Get 19.68g of mud phosphorus from Kunyang Phosphorus Plant with an average phosphorus content of 45.1%, containing about 8.87g of phosphorus. The ratio is 5:1 into the reactor to react at a temperature of 80°C, and the nitrogen carrier gas flow rate is 25mL / min.

[0044] The washing liquid is 85% concentrated phosphoric acid;

[0045] Fill the primary absorption tube with 100mL of 0.75% NaClO solution, pH=9;

[0046] Fill the secondary absorption tube with 100mL of 7% NaClO solution, pH=9;

[0047] Fill the tertiary absorption tube with 100mL of 7% NaClO solution, pH=13;

[0048] 90.21 g of modified activated carbon was placed in the adsorption tube.

[0049] The results of the absorption test are as follows:

[0050] Table 3 Absorption test results

[0051] test results

reactor

1 # absorption tube

2 # absorption tube

3 # absorption tube

Sodium hypophosphite content / g

14.54

2.64

1.175

0.881

Phosph...

Embodiment 3

[0056] Take 22.84g of phosphorus from the Kunyang Phosphorus Plant with a phosphorus content of 35.6%, containing about 8.13g of phosphorus, according to the water-to-phosphorus ratio of 105:1, the alkali-to-phosphorus ratio of 3.5:1, the proportioning of sodium hydroxide and calcium hydroxide 5:1 into the reactor for reaction at a temperature of 90 ° C, nitrogen carrier gas flow rate of 40mL / min.

[0057] The washing liquid is 90% concentrated phosphoric acid;

[0058] Fill the primary absorption tube with 100mL of 0.75% NaClO solution, pH=9;

[0059] Fill the secondary absorption tube with 100mL of 7% NaClO solution, pH=9;

[0060] Fill the tertiary absorption tube with 100mL of 7% NaClO solution, pH=13;

[0061] 99.83 g of modified activated carbon was placed in the adsorption tube.

[0062] The results of the absorption test are as follows:

[0063] Table 5 Absorption test results

[0064] test results

reactor

1 # absorption tube

2 # absorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com