Nanometer ceramic alumina coated abrasive tool and manufacture method thereof

A technology of nano-ceramics and coated abrasives, which is applied to chemical instruments and methods, manufacturing tools, abrasives, etc., can solve problems such as burns, and processing efficiency is difficult to meet the pursuit of efficiency, so as to reduce grinding stress and improve grinding environment , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

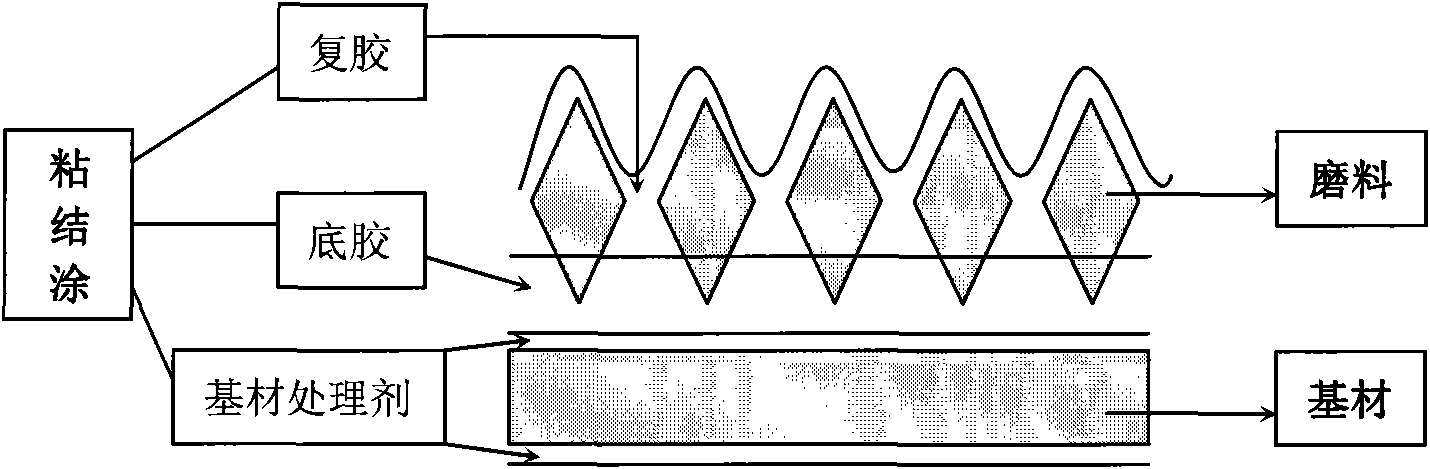

[0024] Such as figure 1 The nano-ceramic alumina-coated abrasive tool shown includes: a base material with opposite upper and lower surfaces, the base material can be a blended cloth or polyester cloth base material, and the base material is treated with a base material treatment agent Pass. There is a primer layer on the upper surface of the base material, and the rubber material in the primer layer contains the following materials by weight: 100 parts by weight of liquid water-soluble phenolic resin, 20-100 parts by weight of ultra-fine calcium carbonate, 0.1-1.0 parts by weight parts of coupling agent, the coating amount of the primer layer is 30 ~ 800g / m 2 , the viscosity of the primer layer is 500-6000CP at 20°C, and the physical and chemical parameters of the liquid water-soluble phenolic resin are as follows: the solid content is 60-80%, the water solubility is 50-280%, and the phenolic resin of 0.5g The polymerization rate is 80-280 seconds at 135°C, and the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com