A Radiographic Digital Imaging Inspection System for Circumferential Welds of Pressure Equipment

A technology of pressure-bearing equipment and digital imaging, which is applied in the use of radiation for material analysis, etc., can solve problems such as difficult to discard liquid medicine, large fluctuations in the influence of ambient temperature and magnetic field, and environmental pollution, so as to reduce the radiation dose and its scope of influence , significant economic and social benefits, and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

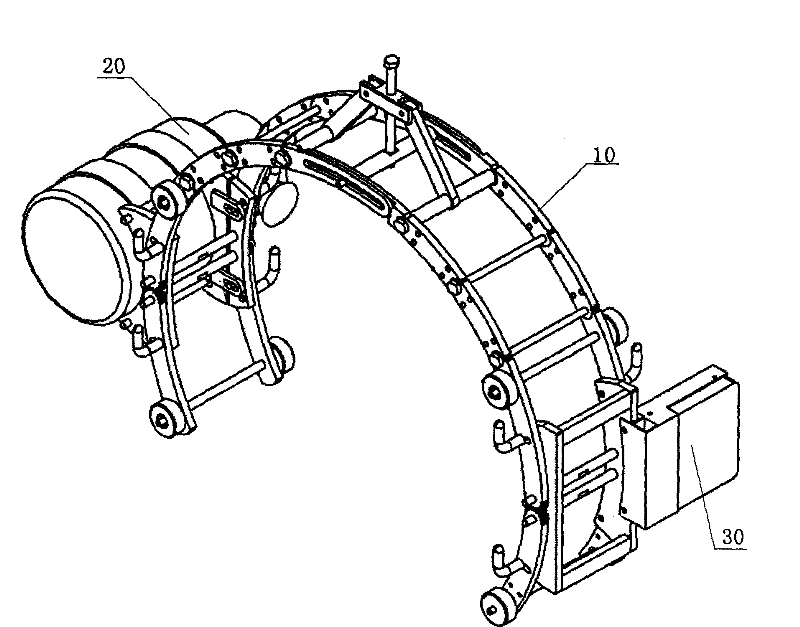

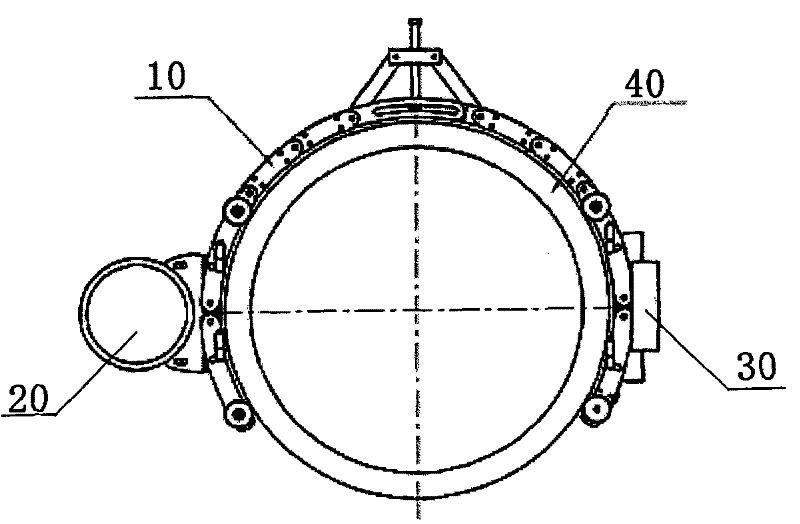

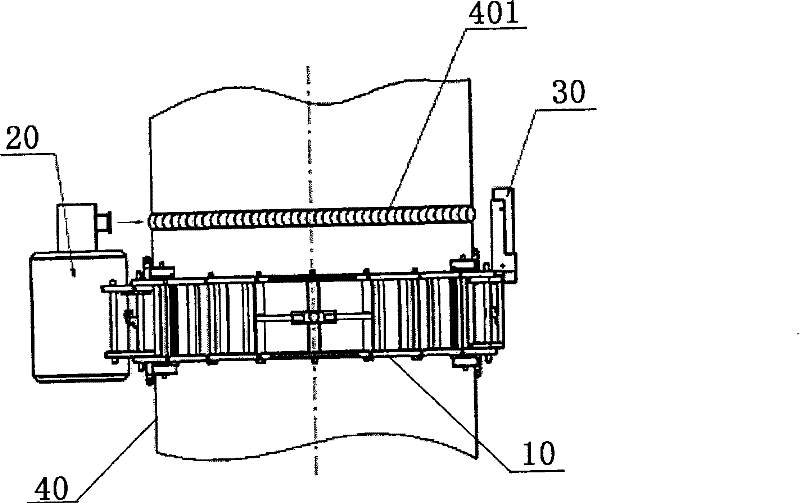

[0017] figure 1 It is a three-dimensional view of the radiography digital imaging detection system for the girth weld of the pressure equipment according to the embodiment of the present invention, Figure 2a for figure 1 main view of Figure 2b for figure 1 top view. The following combination Figure 1-Figure 2b Describe how the system works. The system includes: an automatic scanning device 10 for pressure-bearing equipment, which is arranged outside the pressure-bearing equipment 40, and is used to rotate around the axial direction of the pressure-bearing equipment 40; a ray emitting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com