Power taking method for large-current high-voltage transmission bus

A power transmission bus and high-current technology, which is applied in the field of high-current and high-voltage power transmission bus, can solve the problems of volume and installation constraints, inability to work with instruments and devices, and poor high-temperature resistance of rechargeable batteries, and achieve simple structure and installation , save the cost of installation materials, good effect of explosion-proof sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical scheme of the present invention is described below in conjunction with accompanying drawing and embodiment:

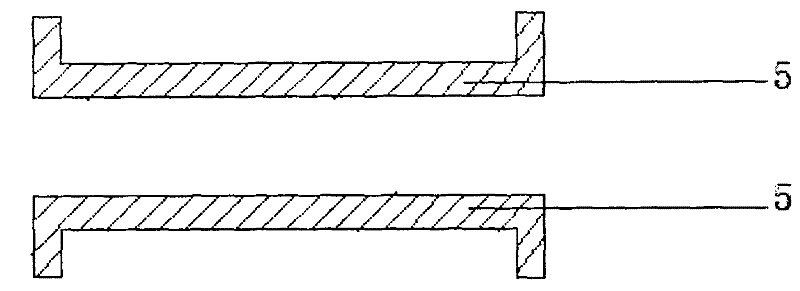

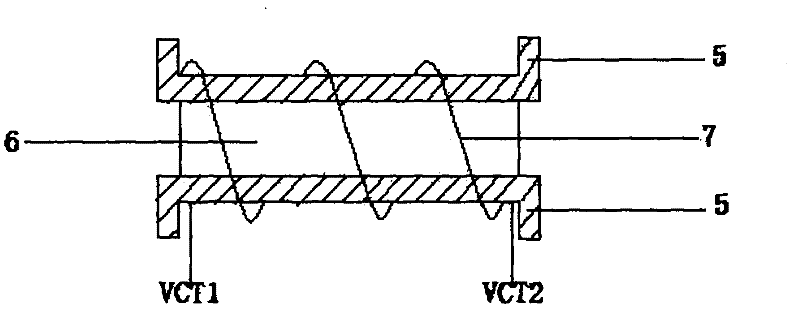

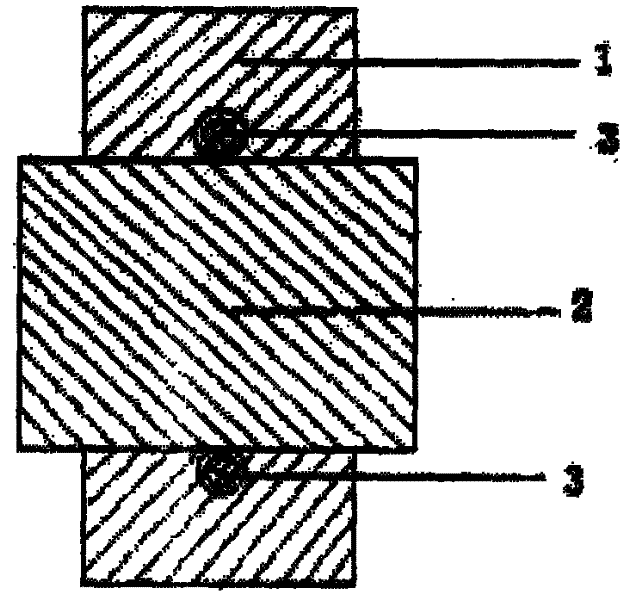

[0037] figure 1 It is a longitudinal section schematic diagram of the magnetic induction coil frame 5, and the magnetic induction coil frame 5 is made of polytetrafluoroethylene. figure 2 It is a schematic diagram of the structure of the magnetic induction coil, in which the silver-plated copper wire 7 is wound on the coil frame 5, and the powder of magnetic iron oxide powder is compacted and packaged inside the coil frame 5 to form the iron core 6, VCT1, VCT2 Connected to the filter circuit as wiring. As preferably, the length of the bobbin 5 is 60mm, the diameter is 15mm, and the wall thickness is 1mm. The diameter of the silver-plated copper wire 7 is 2mm and is wound on the bobbin 5 at intervals of 1mm. The magnetic iron oxide The specification of the powder is 2000 mesh, and the inside of the coil frame 5 is sealed with 502 glue drops. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com