Ultrasound field intensity coupling suspension driving device of metal suspension liquid and using method thereof

A suspension drive and suspension technology, which is applied in the field of metal material alloying and composite material preparation devices, can solve the problems of difficulty in continuous production, low surface reactivity, and low renewal strength of the reaction interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

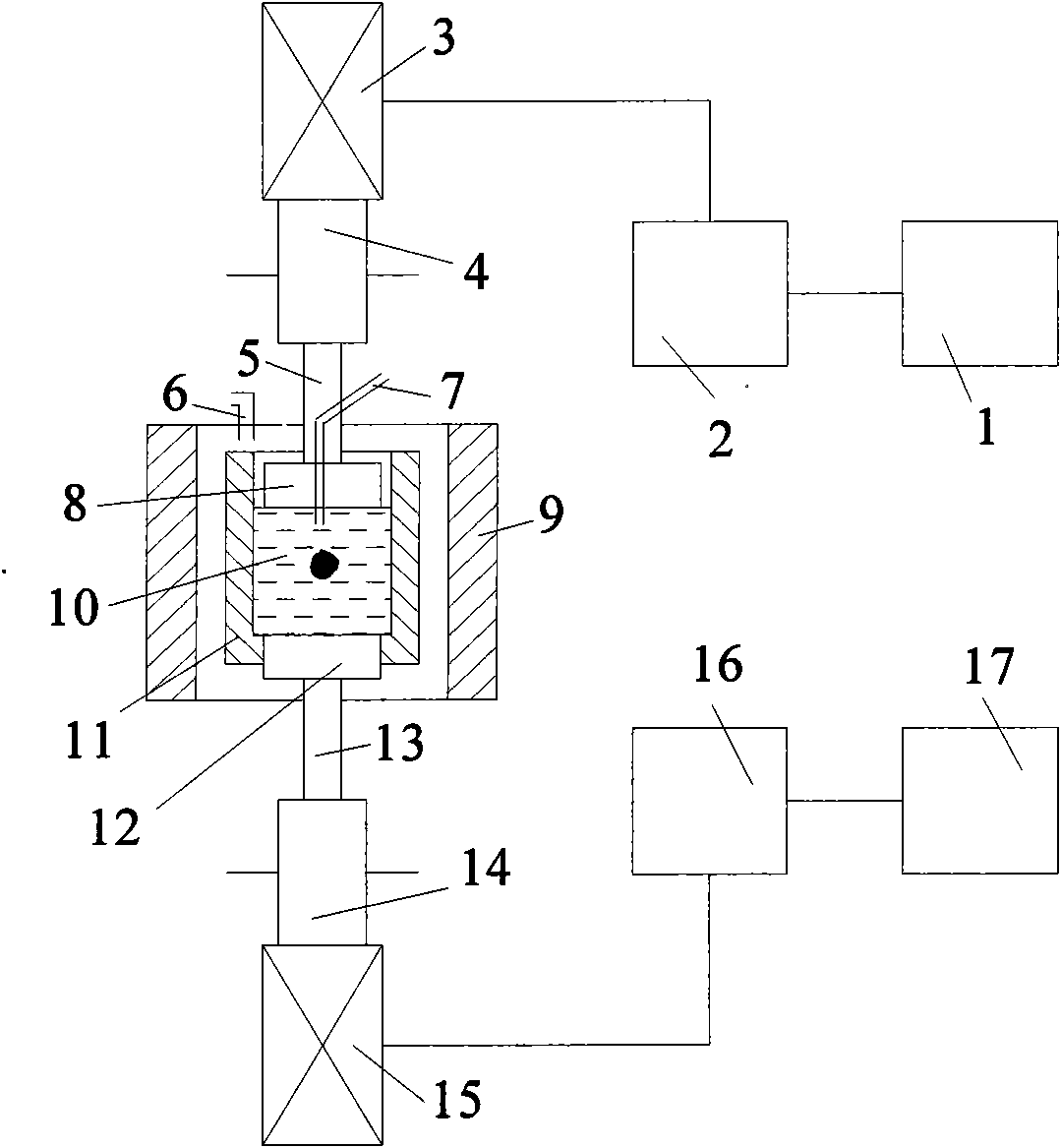

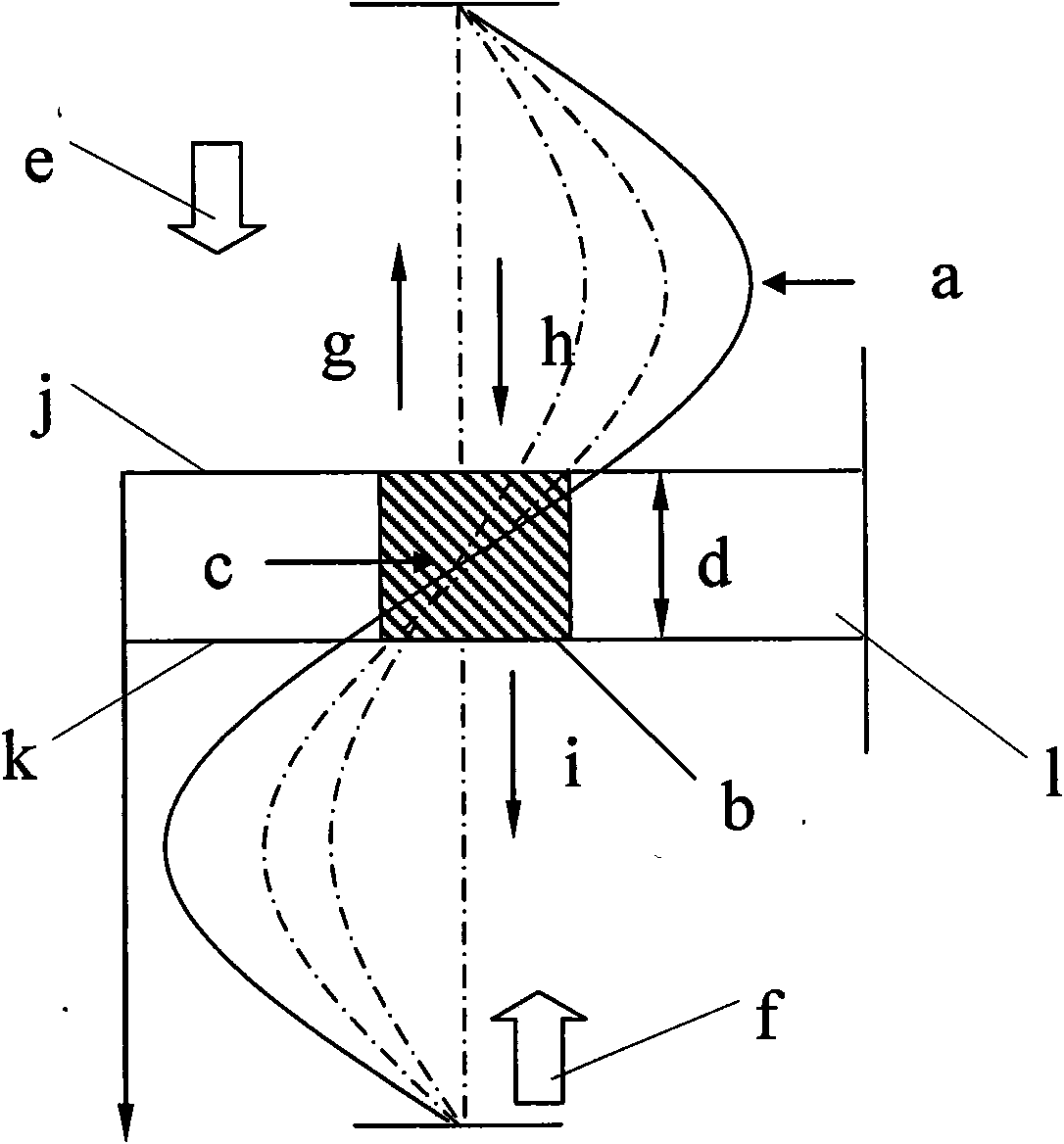

[0050] The structure of the metal suspension ultrasonic field strength coupling suspension drive device is as follows: figure 1 As shown, the upper power regulator 1 and the upper ultrasonic generator 2 are connected by wires, the upper ultrasonic generator 2 and the upper ultrasonic transducer 3 are connected by wires, and the upper ultrasonic transducer 3 and the upper horn 5 are assembled together. The upper horn 5 is assembled with the upper coupling radiation block 8; the lower power regulator 17 is connected with the lower ultrasonic generator 16 through a wire, the lower ultrasonic generator 16 is connected with the lower ultrasonic transducer 15 through a wire, and the lower ultrasonic transducer The device 15 is assembled with the lower horn 13, and the lower horn 13 is assembled with the lower coupling radiation block 12; the upper end of the upper horn 5 is covered with an upper water cooling jacket 4, and the lower end of the lower horn 13 is covered with The lower...

Embodiment 2

[0060] The metal suspension ultrasonic field strength coupling levitation driving device used is the same as that in Embodiment 1.

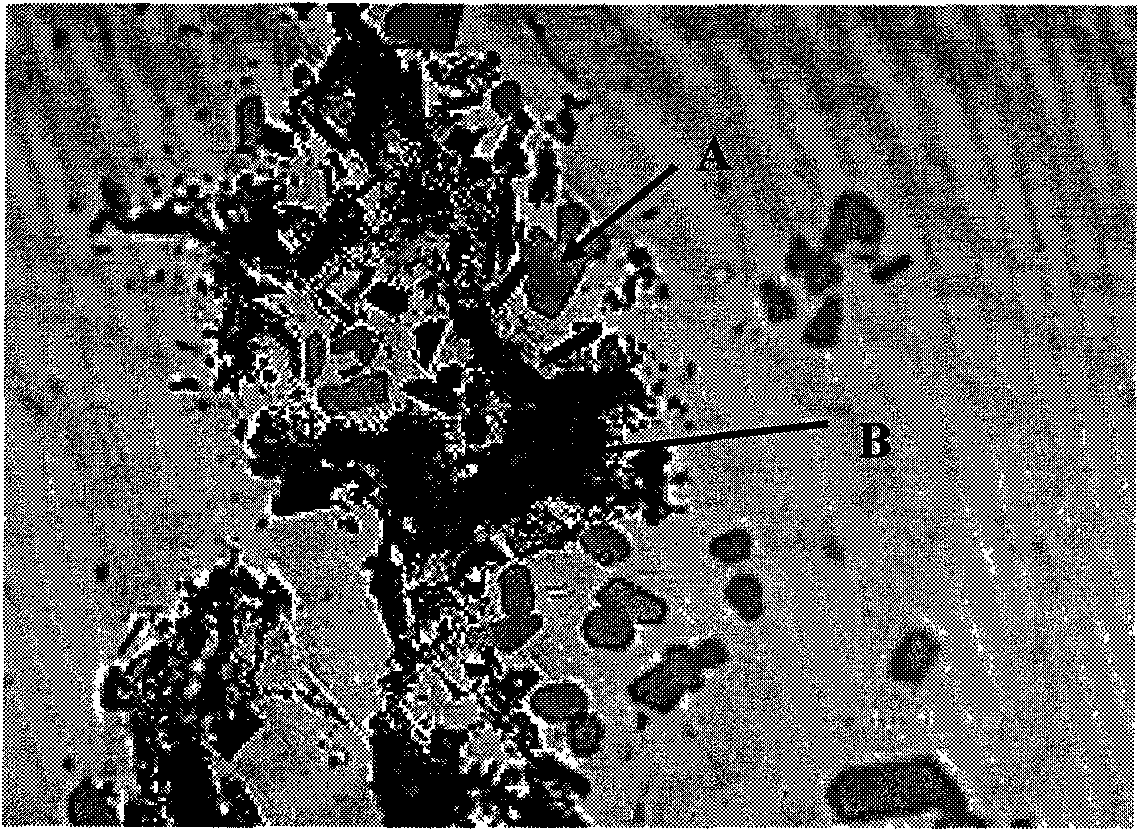

[0061] Three parallel experiments on the preparation of high-performance Al-12Si alloys were carried out using Al-20Si master alloys: the Al-20Si alloy was placed in a mold, heated to a temperature of 760 °C to become an alloy melt under the condition of feeding a protective gas, and then Add Al to react, the reaction time is 20, 22 and 25min respectively, the addition of Al is 150% of the total weight of the Al-20Si master alloy; the flow rate of the protective gas is controlled at 2, 2.4 and 2.5l / min respectively, and the protective gas is A mixture of hydrogen and argon, the volume ratio of hydrogen and argon in decibels is 1:5, 1:4 and 1:6.

[0062] Then adopt the mode described in embodiment 1 to carry out ultrasonic field coupling to alloy molten liquid emission ultrasonic wave, the frequency of upper sonotrode emitting sound wave is 20kHz,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com