Composite powder body by utilizing alumina for coating barium strontium titanate and preparation method thereof

A technology of coating barium strontium titanate and composite powder, which is applied in the field of powder surface treatment and microwave dielectric ceramic materials, can solve the problems of affecting electrical properties and material grains are too large, and achieve the effect of optimizing dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

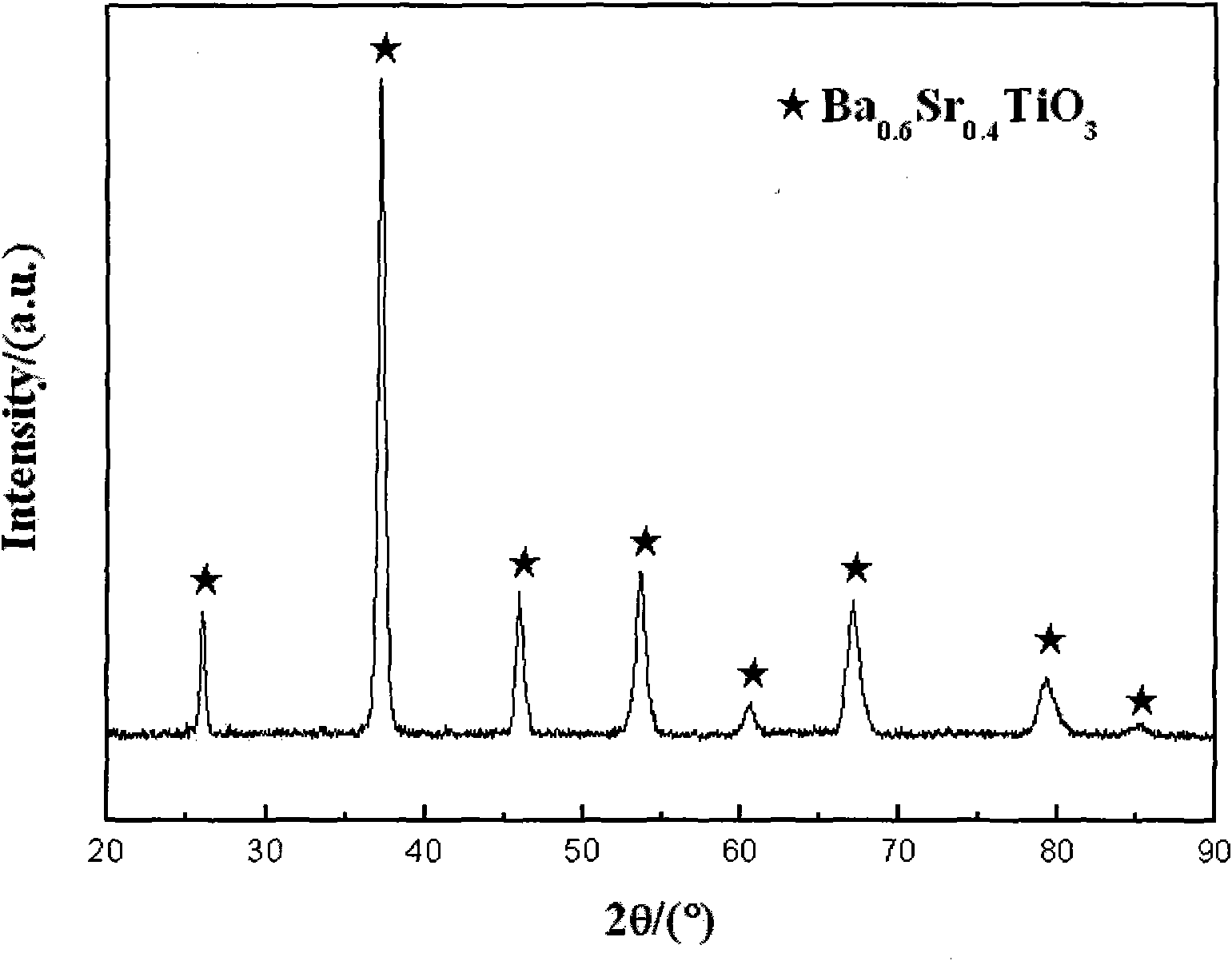

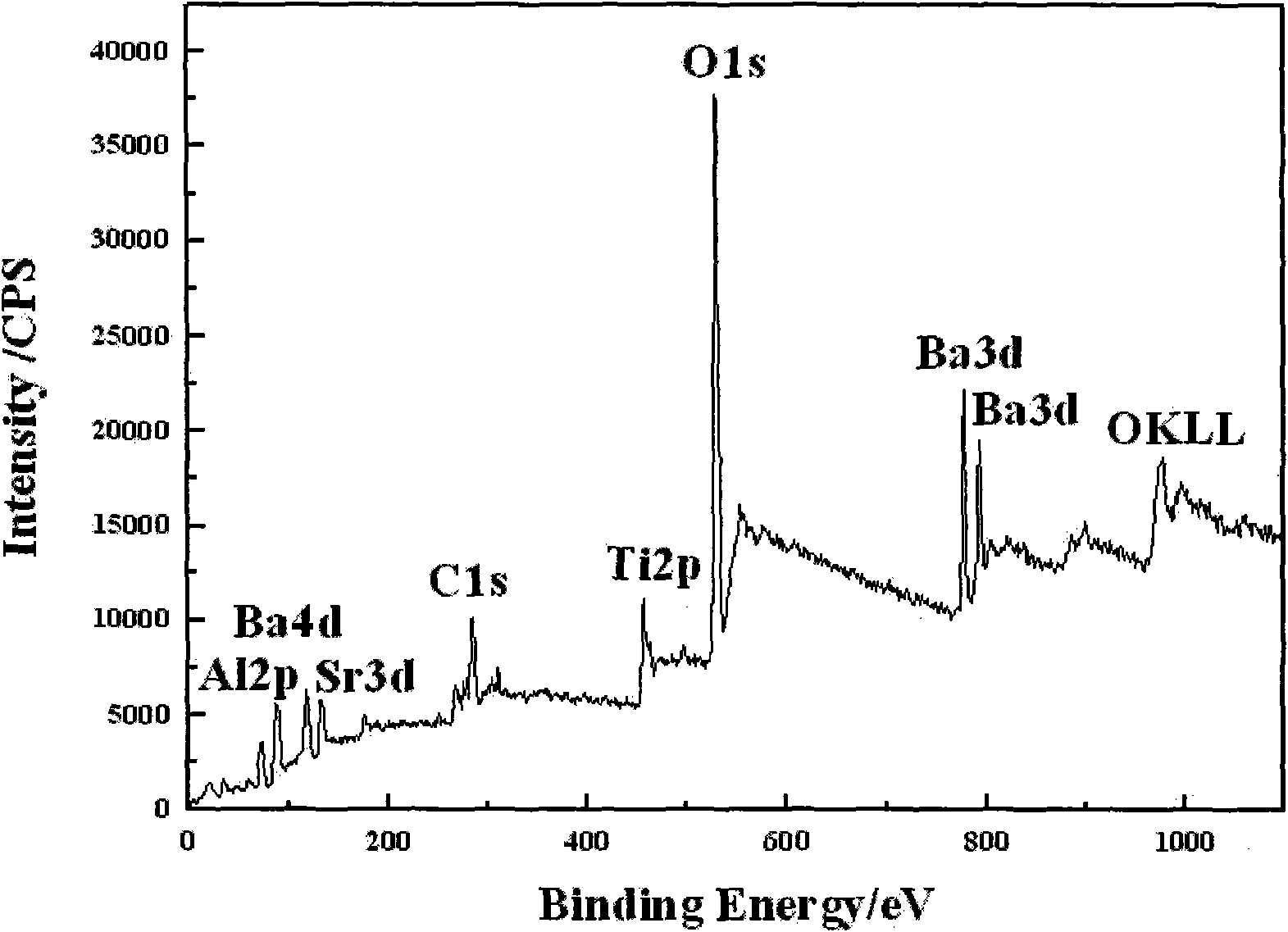

[0016] In this example, Ba 0.6 Sr 0.4 TiO 3 and AlCl 3 It is a precursor material, and the composition of the precursor material is (1-y) Ba 0.6 Sr 0.4 TiO 3 +yAlCl 3 , where y=25wt%. Deionized water was used as a solvent, and ammonia water was used to adjust the pH value of the solution, and PMAA-NH 4 As a dispersant, PMAA-NH 4 The average molecular weight is 5000, and Al is prepared by liquid phase coating method 2 o 3 Coated Ba 0.6 Sr 0.4 TiO 3 Composite powder, specific preparation steps are as follows:

[0017] (1) Preparation of Ba 0.6 Sr 0.4 TiO 3 Powder: Analytical pure BaCO 3 , SrCO 3 、TiO 2 As raw material, according to Ba 0.6 Sr 0.4 TiO 3 The stoichiometric ratio ingredients were ball milled in anhydrous ethanol medium for 12 hours; the powder was dried and pre-calcined at 1100°C for 3 hours to obtain pure Ba 0.6 Sr 0.4 TiO 3 Powder; powder drying temperature is 80°C;

[0018] (2) Preparation of Ba 0.6 Sr 0.4 TiO 3 Stable suspension: usi...

Embodiment 2

[0023] In this example, Ba 0.7 Sr 0.3 TiO 3 and AlCl 3 It is a precursor material, and the composition of the precursor material is (1-y) Ba 0.7 Sr 0.3 TiO 3 +yAlCl 3 , where y=40wt%. Deionized water was used as a solvent, and ammonia water was used to adjust the pH value of the solution, and PMAA-NH 4 As a dispersant, PMAA-NH 4 The average molecular weight is 5000, and Al is prepared by liquid phase coating method 2 o 3 Coated Ba 0.7 Sr 0.3 TiO 3 Composite powder, specific preparation steps are as follows:

[0024] (1) Preparation of Ba 0.7 Sr 0.3 TiO 3 Powder: Analytical pure BaCO 3 , SrCO 3 、TiO 2 As raw material, according to Ba 0.7 Sr 0.3 TiO 3 The stoichiometric ratio ingredients were ball milled in anhydrous ethanol medium for 12 hours; after the powder was dried, it was pre-calcined at 1200 °C for 6 hours to obtain pure Ba 0.7 Sr 0.3 TiO 3 Powder; powder drying temperature is 80°C;

[0025] (2) Preparation of Ba 0.7 Sr 0.3 TiO 3 Stable susp...

Embodiment 3

[0030] In this example, Ba 0.3 Sr 0.7 TiO 3 and AlCl 3 It is a precursor material, and the composition of the precursor material is (1-y) Ba 0.3 Sr 0.7 TiO 3 +yAlCl 3 , where y=50wt%. Deionized water was used as a solvent, and ammonia water was used to adjust the pH value of the solution, and PMAA-NH 4 As a dispersant, PMAA-NH 4 The average molecular weight is 5000, and Al is prepared by liquid phase coating method 2 o 3 Coated Ba 0.3 Sr 0.7 TiO 3Composite powder, specific preparation steps are as follows:

[0031] (1) Preparation of Ba 0.3 Sr 0.7 TiO 3 Powder: Analytical pure BaCO 3 , SrCO 3 、TiO 2 As raw material, according to Ba 0.3 Sr 0.7 TiO 3 The stoichiometric ratio ingredients were ball milled in anhydrous ethanol medium for 24 hours; after the powder was dried, it was pre-calcined at 1100°C for 3 hours to obtain pure Ba 0.3 Sr 0.7 TiO 3 Powder; powder drying temperature is 80°C;

[0032] (2) Preparation of Ba 0.3 Sr 0.7 TiO 3 Stable suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com