An optical waveguide, method for preparing same and wavelength converter

A technology of optical waveguide and waveguide layer, which is applied in the field of communication, can solve the problems of reducing conversion efficiency, low waveguide manufacturing temperature, and enhancement of frequency-doubled optical absorption, so as to reduce photoinduced absorption, widen pump bandwidth, and improve conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

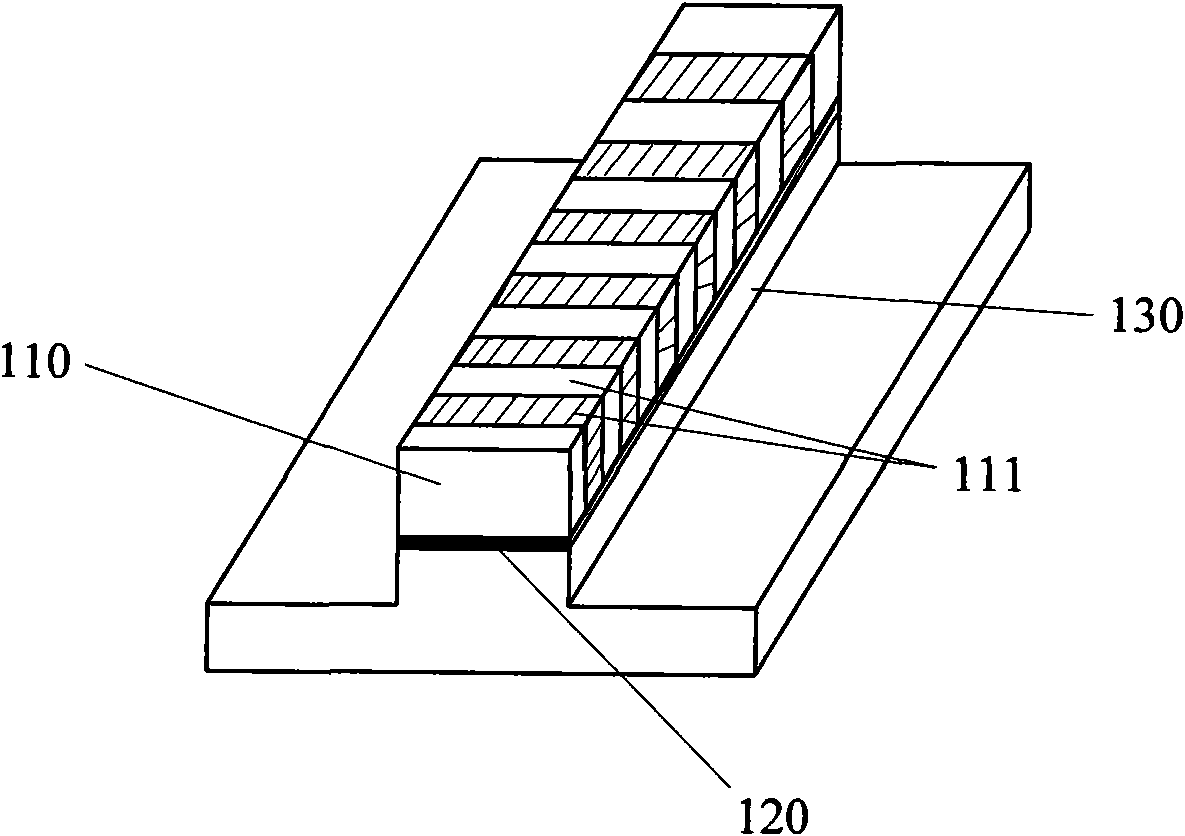

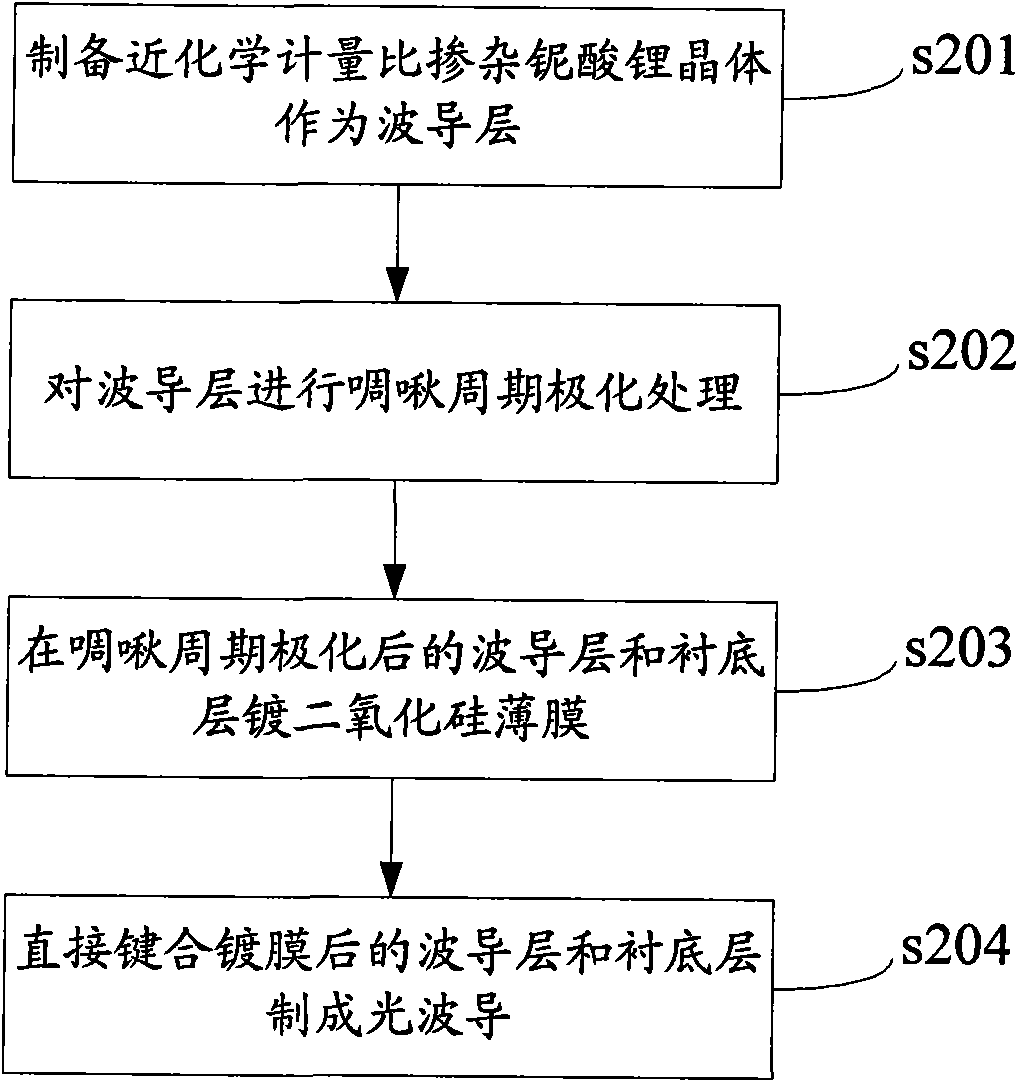

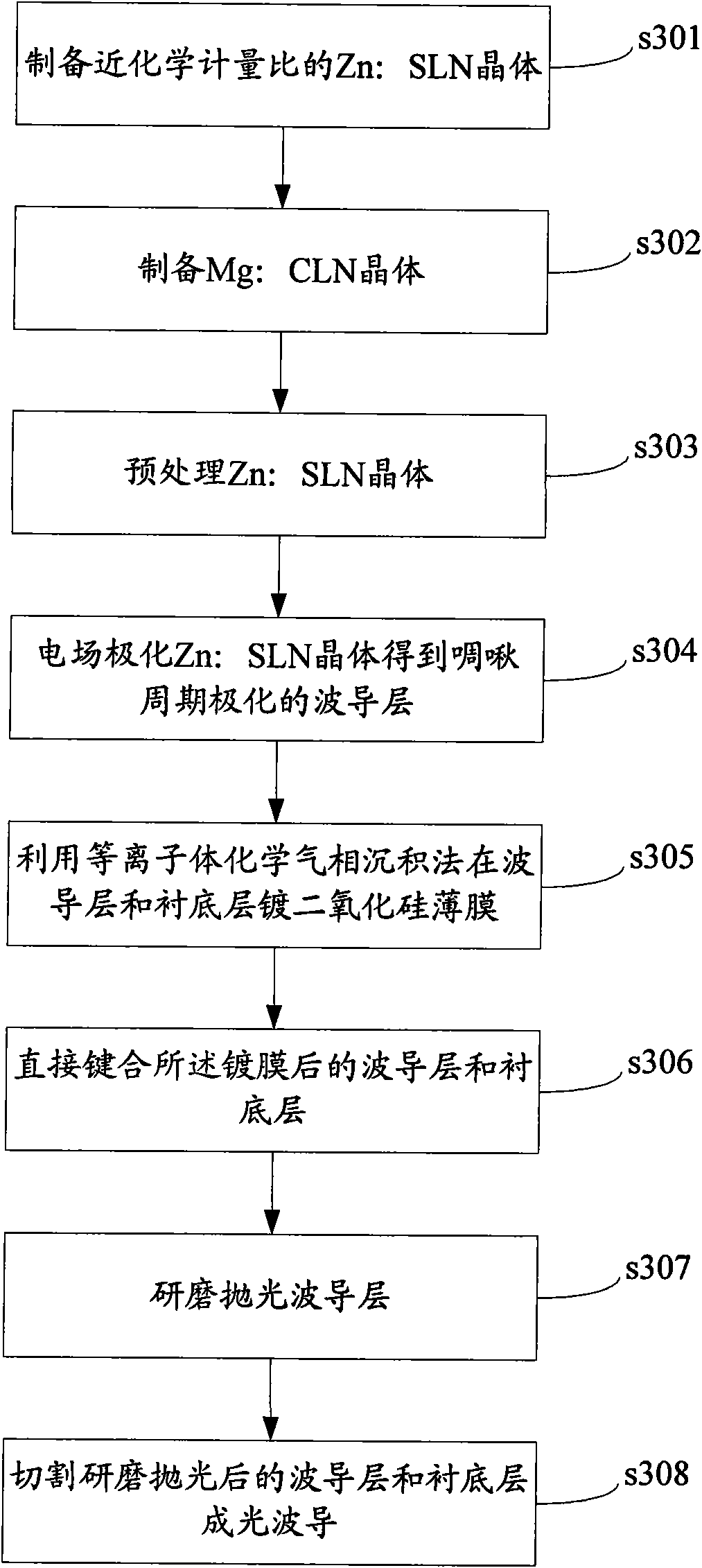

[0026] An embodiment of the present invention provides an optical waveguide, such as figure 1 As shown, the optical waveguide includes a chirped periodically polarized near-stoichiometric lithium niobate crystal waveguide layer 110, a Si-containing film 120 and a substrate 130; the cross-section of the optical waveguide is "convex" Shape: near-stoichiometric doped lithium niobate crystal waveguide layer 110 is on the upper layer of the optical waveguide, and is bonded to the lower substrate 130 through the middle thin film 120 .

[0027] The crystal polarity of the nearly stoichiometric doped lithium niobate crystal waveguide layer 110 changes periodically, and the polarization period increases linearly, forming a chirped periodic grating structure 111; the cross section of the waveguide layer 110 is rectangular or square. The material of the thin film 120 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com