Chitosan nano particles embedded with alpha-galactosidase and preparation method thereof

A technology of galactosidase and chitosan nanometer, which is applied in the molding or processing of animal feed, animal husbandry, additional food elements, etc. The effect of roundness, good spheroidization and simple preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

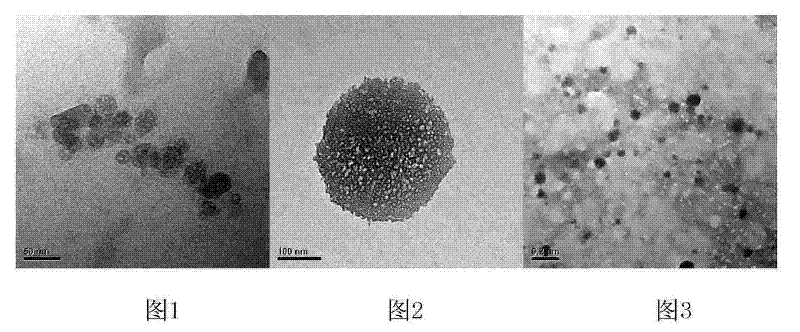

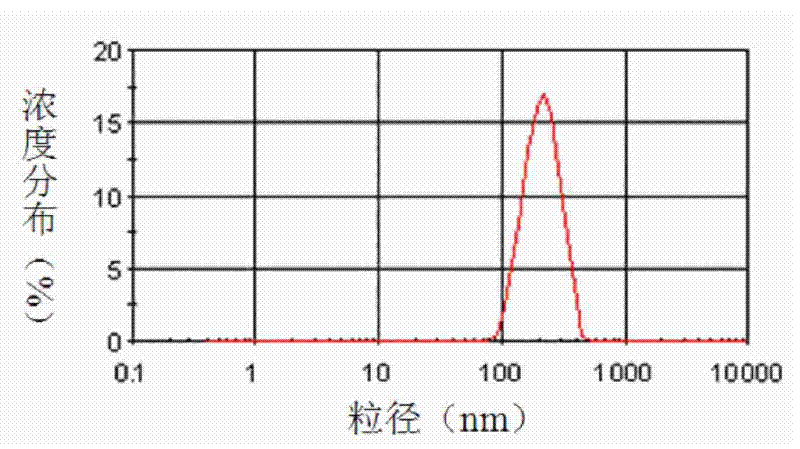

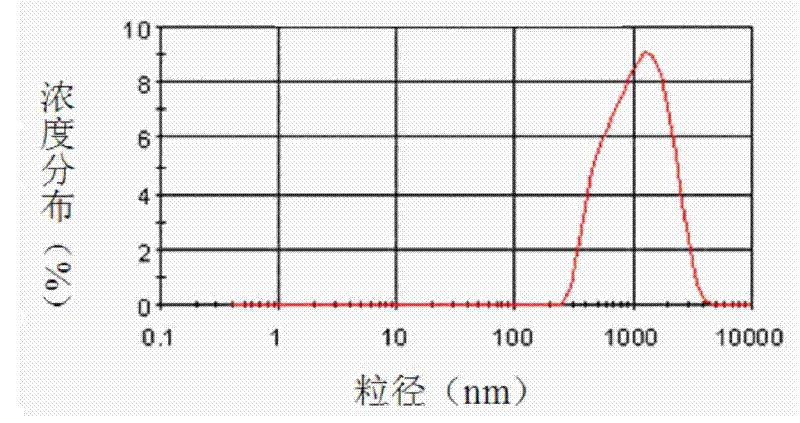

Image

Examples

Embodiment 1

[0034] Dissolve 50mg chitosan (50kd) in 50mL 1% acetic acid solution, adjust the pH to 4.0; slowly add an equal volume of α-galactosidase crude enzyme solution (0.1mg / mL) under magnetic stirring; Add 25mL sodium tripolyphosphate solution (1mg / mL) dropwise to the α-galactosidase; stir at room temperature for 30 minutes, the α-galactosidase mixture presents a uniform blue-white color, that is, the embedded α-galactosidase has been formed. Chitosan nanoparticles of lactosylase. The encapsulation efficiency of α-galactosidase was 63.0%; under the condition of pH 5.5, the tolerance was increased by 35.5% after warming at 60°C for 30 minutes; under the condition of pH 5.5, the enzyme activity was lost by 6.9% when stored at room temperature for 90 days; Under the environment of pH 3.0, the release rate within 10 minutes was 93.2%.

Embodiment 2

[0036] Dissolve 1000mg chitosan (1800kd) in 50mL 1% acetic acid solution, adjust the pH to 6.0; slowly add an equal volume of α-galactosidase crude enzyme solution (5.0mg / mL) under magnetic stirring; Add 250mL sodium tripolyphosphate solution (1mg / mL) dropwise to the α-galactosidase mixture; stir at room temperature for 30 minutes, the α-galactosidase mixture appears blue-white with a small amount of flocculent precipitate, namely Chitosan nanoparticles entrapping alpha-galactosidase have been formed. The encapsulation efficiency of α-galactosidase was 72.5%; under the condition of pH 5.5, the tolerance was increased by 50.2% after warming at 60°C for 30 minutes; under the condition of pH 5.5, the enzyme activity was lost by 4.6% when stored at room temperature for 90 days; The release rate was 82.4% within 10 minutes under the environment of pH 10.0.

Embodiment 3

[0038] Dissolve 475mg chitosan (900kd) in 50mL 1% acetic acid solution, adjust the pH to 5.0; slowly add an equal volume of α-galactosidase crude enzyme solution (2.45mg / mL) under magnetic stirring; Add 120mL sodium tripolyphosphate solution (1mg / mL) dropwise to the α-galactosidase mixture; stir at room temperature for 30 minutes, the α-galactosidase mixture appears uniform blue-white, that is, the embedded α - Chitosan nanoparticles of galactosidase. The encapsulation efficiency of α-galactosidase was 87.3%; under the condition of pH 5.5, the tolerance was increased by 60.3% after warming at 60°C for 30 minutes; under the condition of pH 5.5, the enzyme activity was lost by 2.7% when stored at room temperature for 90 days; The release rate was 35.2% within 10 minutes under the environment of pH 7.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com