Regeneration method of inactivated carbonyl sulfide hydrolysis catalyst taking activated carbon as carrier

A technology of hydrolysis catalyst and carbonyl sulfide, which is applied in the field of regeneration after deactivation of the preparation of carbonyl sulfide hydrolysis catalyst, can solve the problems such as non-regeneration, and achieve the effect of simple regeneration method, high activity, and simple and easy-to-obtain impregnation solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

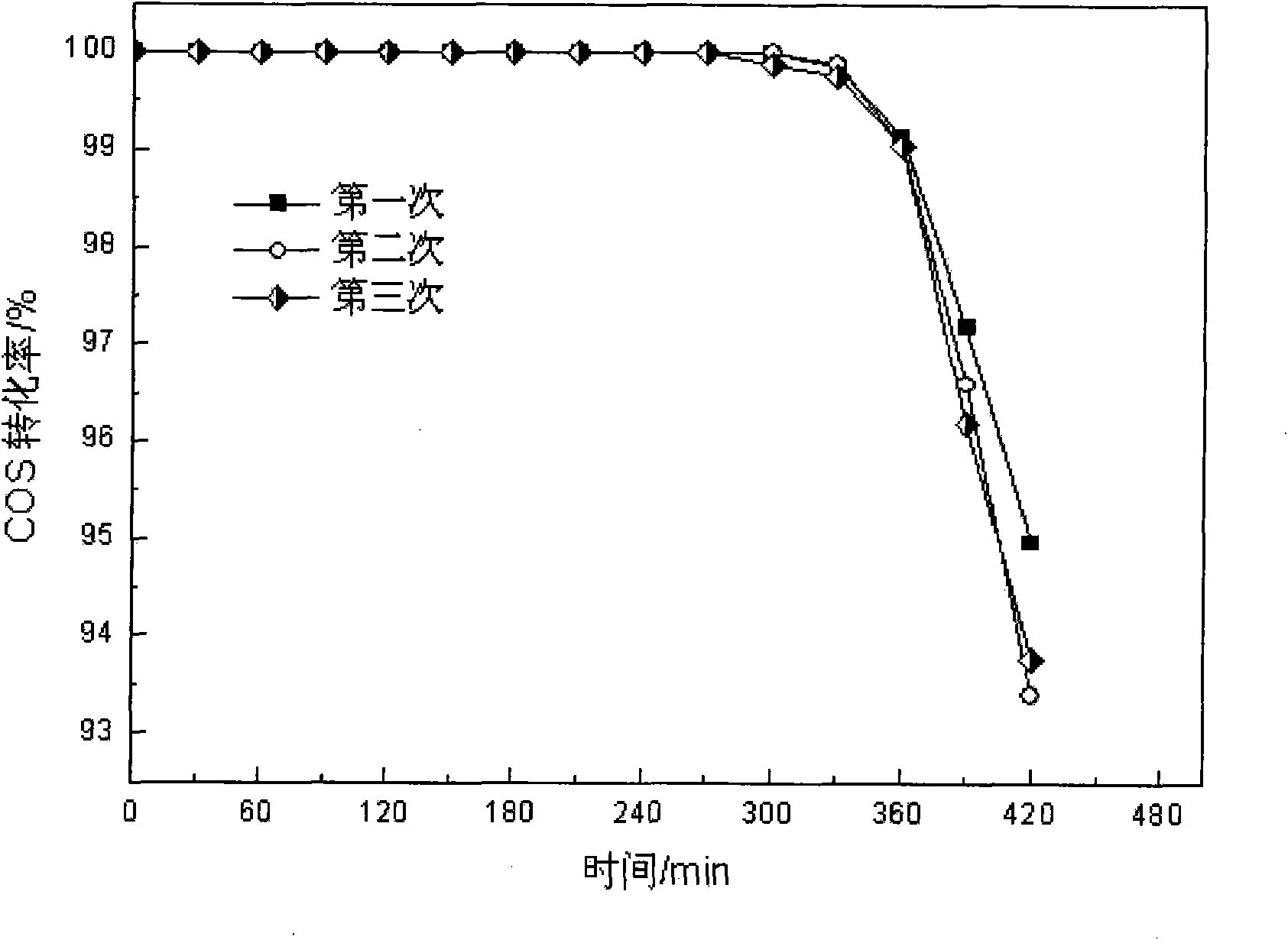

[0023] The 3g carbonyl sulfide hydrolysis catalyst I with the coal-based activated carbon as the carrier after the above-mentioned deactivation is put in a conventional tube furnace, under N 2 Under air protection, roast at 150°C for 3 hours, then wash with distilled water for 40 minutes on a conventional ultrasonic instrument at a temperature of 30°C and a frequency of 45KHz ultrasonic waves, dry at 120°C for 3 hours, and then add 0.24g Na 2 CO 3 Dissolve in 6ml of distilled water, impregnate the dried catalyst in it, use the same ultrasonic instrument as above, immerse for 20min under the conditions of 30°C and 40Hz ultrasonic assist, and finally dry at 120°C for 3h. The activity test of the catalyst was carried out in a fixed-bed reactor (Φ4mm×100mm), and the reaction conditions were: take 0.4g of the regenerated catalyst, the temperature was 70°C, and the space velocity was 1000h -1 , COS concentration 2565mg / m 3 , the oxygen concentration is 0.5%, and no H is detected a...

Embodiment 2

[0026] Put the deactivated 3g carbonyl sulfide hydrolysis catalyst II with coal-based activated carbon as the carrier in a conventional tube furnace, N 2 Under protection, it was roasted at 200°C for 4h, and then washed with distilled water for 30min on a conventional ultrasonic instrument at a temperature of 30°C and a frequency of 45KHz ultrasonically assisted, and dried at 130°C for 3h, and then 0.3g NaHCO 3Dissolve in 6ml of distilled water, impregnate the dried catalyst in it, use the same ultrasonic instrument as above, immerse for 30min under the assisted conditions of 30°C and 40Hz ultrasonic waves, and finally dry at 110°C for 6h. The activity test of the catalyst was carried out in a fixed-bed reactor (Φ4mm×100mm), and the reaction conditions were: take 0.4g of the regenerated catalyst, temperature 70°C, space velocity 1000h -1 , COS concentration 2245mg / m 3 , the oxygen concentration is 0.5%, and no H is detected at the reaction outlet 2 S, and COS catalytic hydro...

Embodiment 3

[0029] The deactivated 3g carbonyl sulfide hydrolysis catalyst III with coconut shell activated carbon as a carrier is placed in a tube furnace, N 2 Under protection, it was roasted at 250°C for 3h, then washed with distilled water for 20min on a conventional ultrasonic instrument at a temperature of 30°C and a frequency of 28KHz, and then dried at 110°C for 6h, and then 0.27g NaOH was dissolved in Immerse the dried catalyst in 6ml of distilled water, use the same ultrasonic instrument as above, immerse for 40min at 30°C and 40Hz ultrasonic assist conditions, and finally dry at 120°C for 4h. The activity test of the catalyst was carried out in a fixed-bed reactor (Φ4mm×100mm), and the reaction conditions were: take 0.4g of the regenerated catalyst, the temperature was 70°C, and the space velocity was 2000h -1 , COS concentration 1825mg / m 3 , the oxygen concentration is 0.5%, and no H is detected at the reaction outlet 2 S, and COS catalytic hydrolysis purification effect is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com