Membrane electrode integrated component with sealed frames and preparation method thereof

A membrane electrode and sealing frame technology, which is applied in the field of fuel cells, can solve the problems of reducing the internal insulation of the battery, leaking fuel and oxidant, and decreasing the efficiency of the battery, so as to ensure gas barrier properties, simplify assembly and disassembly, and improve airtightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

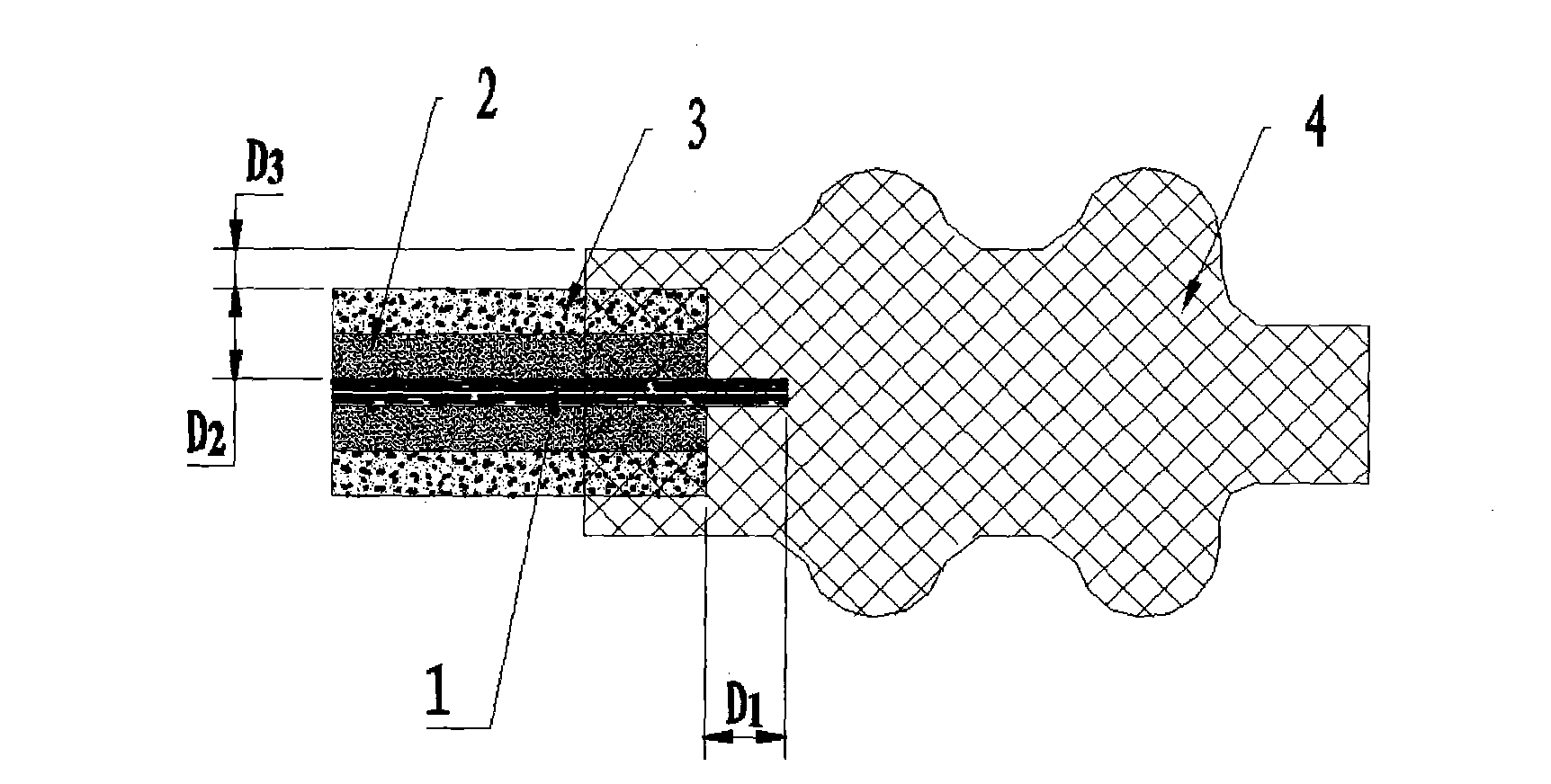

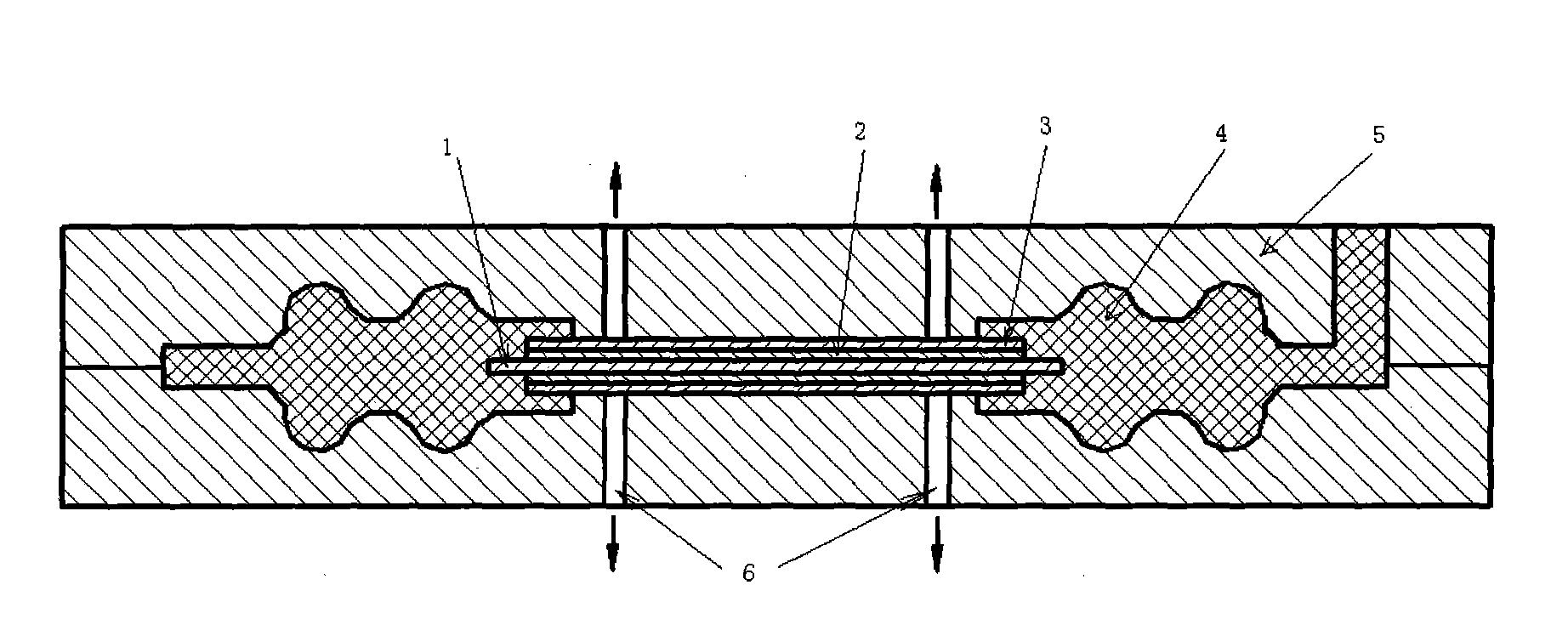

[0025] as attached figure 1 As shown, it is a membrane electrode-sealing frame integrated assembly with two raised sealing lines. Firstly, the membrane and electrode are cut according to the design size to meet the requirements of D2≤D1≤D2+D3. Press into a membrane-electrode preform under the pressure of 1-15MPa and room temperature to 150°C, or press the precisely tailored electrode and a larger-sized membrane using the above conditions, and then trim the membrane around the edge of the electrode. Make it meet the requirements of D2≤D1≤D2+D3. The elastic sealing frame is made of liquid silicone rubber using an injection mold 5 with a vacuum-promoted permeation opening 6 (as attached image 3 ), the two-component liquid silicone rubber penetrates into the micropores on the edge of the electrode catalyst layer 2 and the electrode diffusion layer 3, and the silicone rubber is cured to form an elastomer sealing frame 4, which is designed with two raised sealing lines, which I...

Embodiment 2

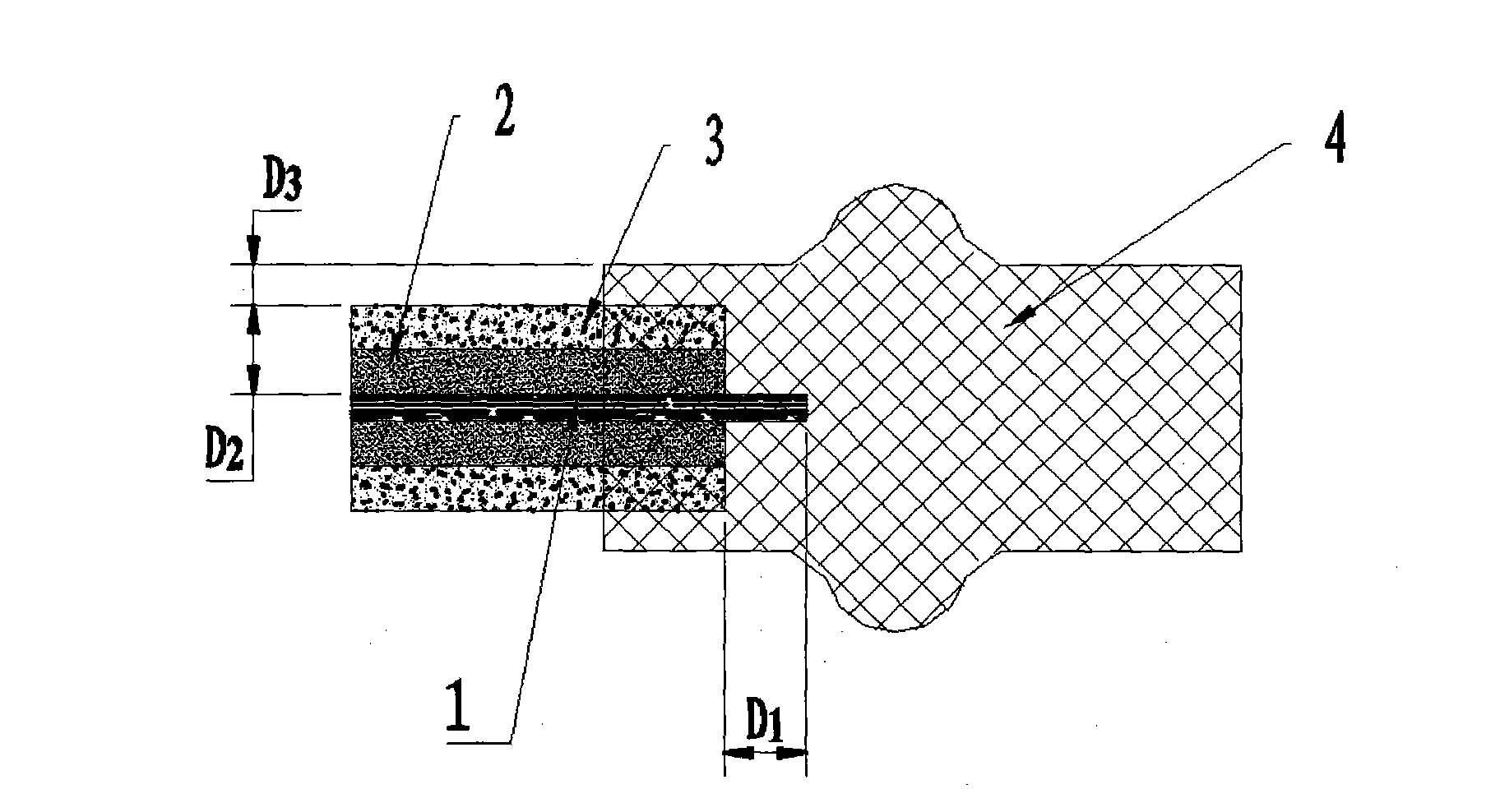

[0027] as attached figure 2 As shown, it is a membrane electrode-sealing frame integrated assembly with a raised sealing line. First, the membrane and electrode are cut according to the design size to meet the requirements of D2≤D1≤D2+D3. Press into a membrane-electrode preform under the pressure of 1-15MPa and room temperature to 150°C, or press the precisely tailored electrode and a larger-sized membrane using the above conditions, and then trim the membrane around the edge of the electrode. Make it meet the requirements of D2≤D1≤D2+D3. Spread the penetration enhancer on the outer edges of the electrodes on both sides of the membrane (as attached Figure 4 In area 7), the elastic sealing frame is made of liquid silicone rubber injection molding, the two-component liquid silicone rubber penetrates into the micropores on the edge of the electrode catalyst layer 2 and the electrode diffusion layer 3, and the silicone rubber is cured to form an elastomer seal Frame 4, a raised...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com